Pyrogenic attack comprehensive recovery process for lead and silver slag leached from bismuth oxide slag

A technology of pyroprocessing and bismuth oxide slag, which is applied in the direction of improving process efficiency and can solve the problem of low direct metal recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

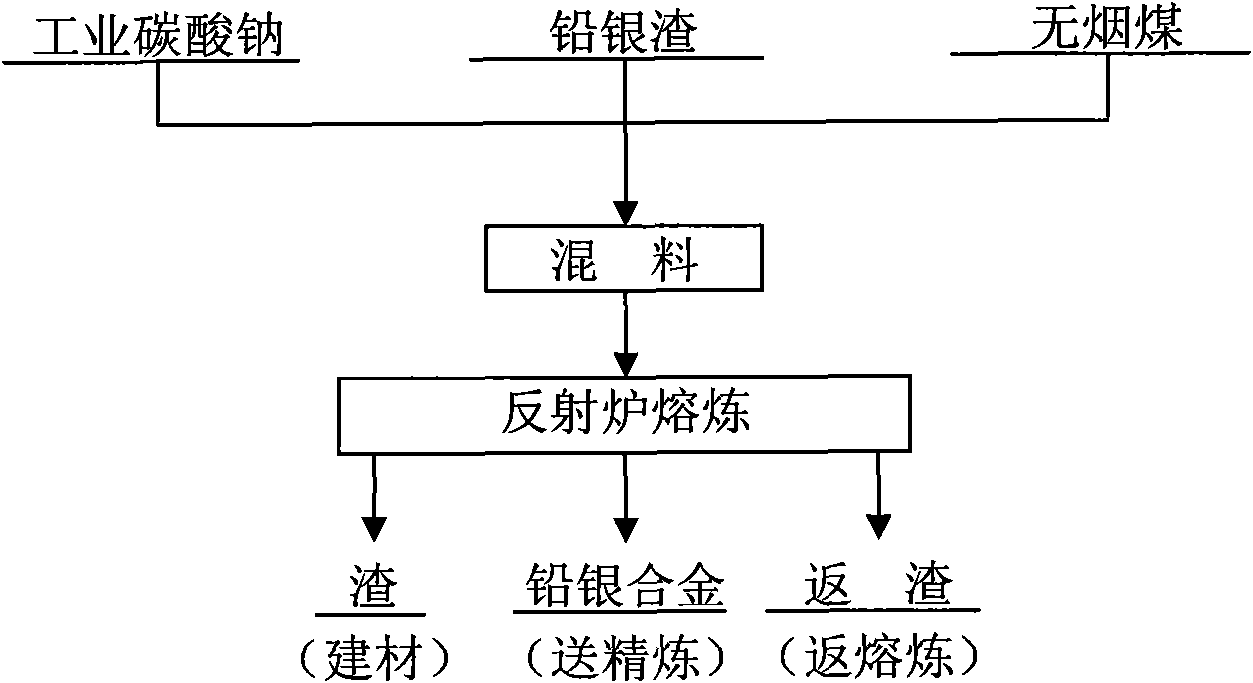

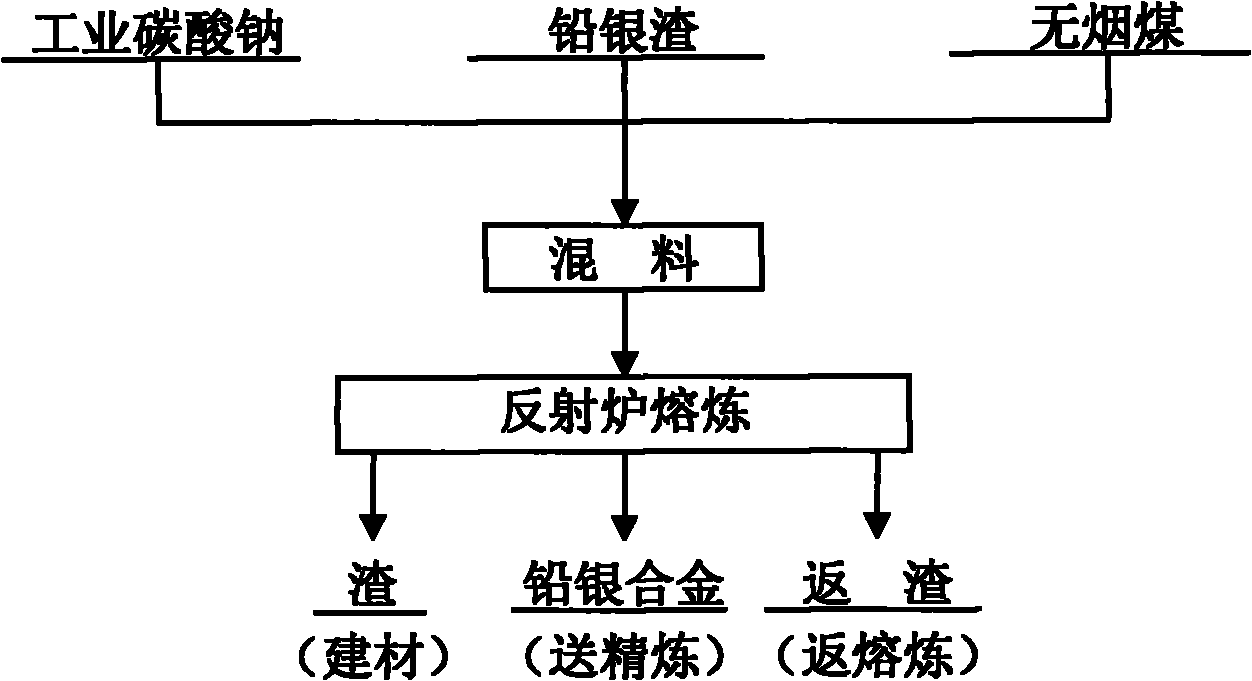

Method used

Image

Examples

Embodiment 1

[0027] The pyroprocessing comprehensive recovery process of lead-silver slag leached from bismuth oxide slag in this embodiment comprises the following major steps:

[0028] (1) the lead-silver slag is crushed, and evenly mixed by the mass ratio of lead-silver slag: industrial sodium carbonate: anthracite=100: 35: 8;

[0029] (2) Add the mixed materials into the reverberatory furnace hearth from the feed port;

[0030] (3) Heat up to 650°C with a coal block and keep warm for 0.5h;

[0031] (4) continue to heat to 1050 ℃, keep warm for 1.5h, so that the whole lead and silver slag can be melted completely as far as possible;

[0032] (5) release the slag on the melt surface;

[0033] (6) after the slagging is completed, the molten lead-silver liquid is put into the lead bucket, and the scum above the lead liquid is removed; cooling obtains the lead-silver alloy;

[0034] (7) Return the slag released from step (5) and the scum or ingredients produced by step (6) to the reverbe...

Embodiment 2

[0036] The pyroprocessing comprehensive recovery process of lead-silver slag leached from bismuth oxide slag in this embodiment comprises the following major steps:

[0037] (1) lead-silver slag is broken, by lead-silver slag: industrial sodium carbonate: the mass ratio of anthracite=100: 40: 10 is evenly mixed;

[0038] (2) Add the mixed materials into the reverberatory furnace hearth from the feed port;

[0039] (3) Heat up to 700°C with coal block and keep warm for 2.5h;

[0040] (4) continue to heat to 1100 ℃, keep warm for 2.5h, so that the whole lead and silver slag can be melted completely as far as possible;

[0041] (5) release the slag on the melt surface;

[0042] (6) after the slagging is completed, the molten lead-silver liquid is put into the lead bucket, and the scum above the lead liquid is removed; cooling obtains the lead-silver alloy;

[0043] (7) Return the slag released from step (5) and the scum or ingredients produced by step (6) to the reverberatory ...

Embodiment 3

[0045] The pyroprocessing comprehensive recovery process of lead-silver slag leached from bismuth oxide slag in this embodiment comprises the following major steps:

[0046] (1) lead-silver slag is broken, by lead-silver slag: industrial sodium carbonate: the mass ratio of anthracite=100: 30: 9 is evenly mixed;

[0047] (2) Add the mixed materials into the reverberatory furnace hearth from the feed port;

[0048] (3) Heating the temperature to 600°C with a coal block and keeping it warm for 1 hour;

[0049] (4) continue to heat to 1000 ℃, keep warm for 2 hours, so that the whole lead and silver slag can be melted completely as far as possible;

[0050] (5) release the slag on the melt surface;

[0051] (6) after the slagging is completed, the molten lead-silver liquid is put into the lead bucket, and the scum above the lead liquid is removed; cooling obtains the lead-silver alloy;

[0052] (7) Return the slag released from step (5) and the scum or ingredients produced by st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com