Joint structure of composite pipe and pipe assembly

An interface structure, composite pipe technology, applied in the direction of pipes/pipe joints/fittings, non-removable pipe connections, passing components, etc., can solve problems affecting product performance, toughness and plasticity decline, etc., to eliminate the phenomenon of lattice distortion. , the effect of eliminating lattice distortion and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

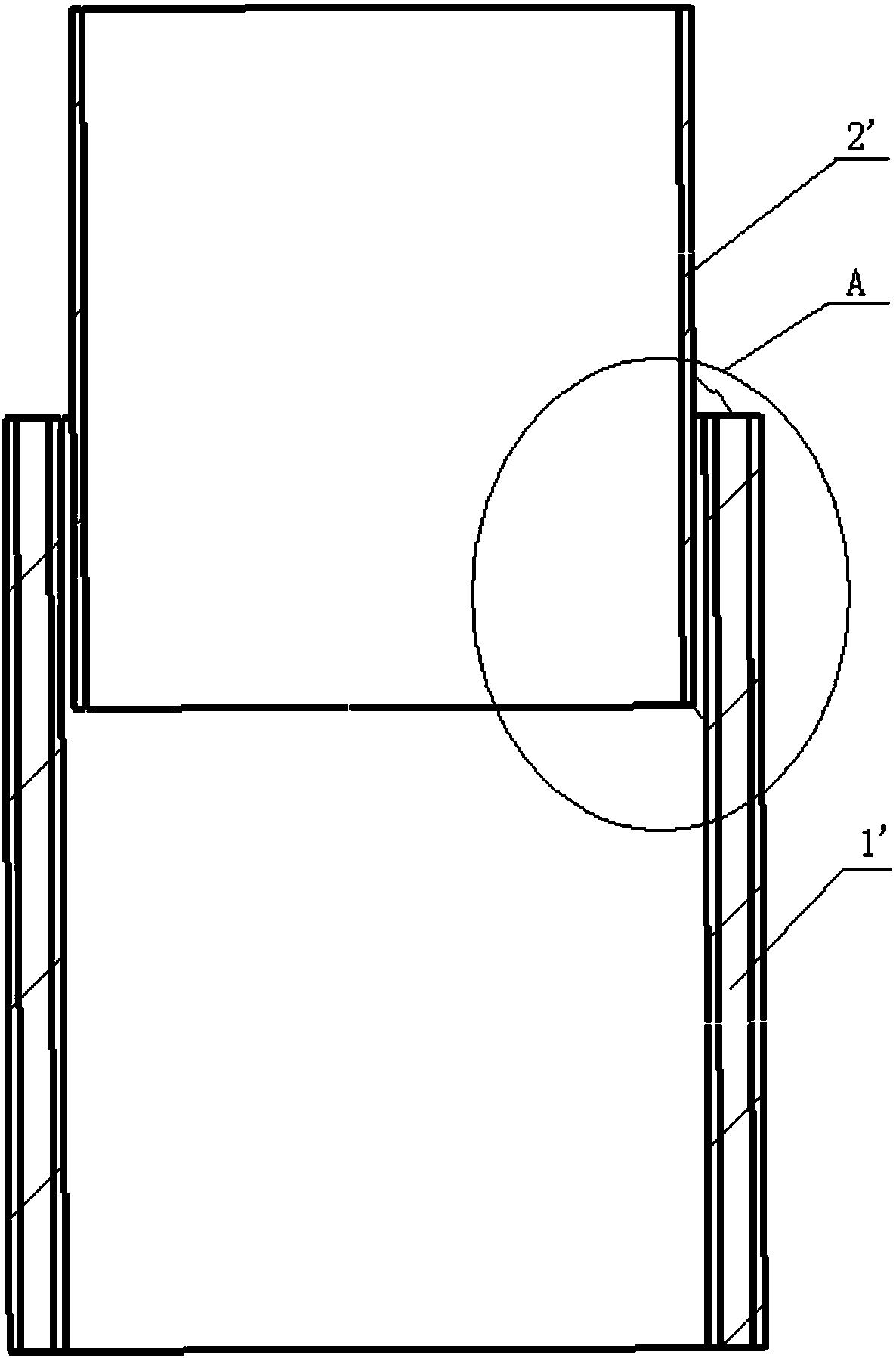

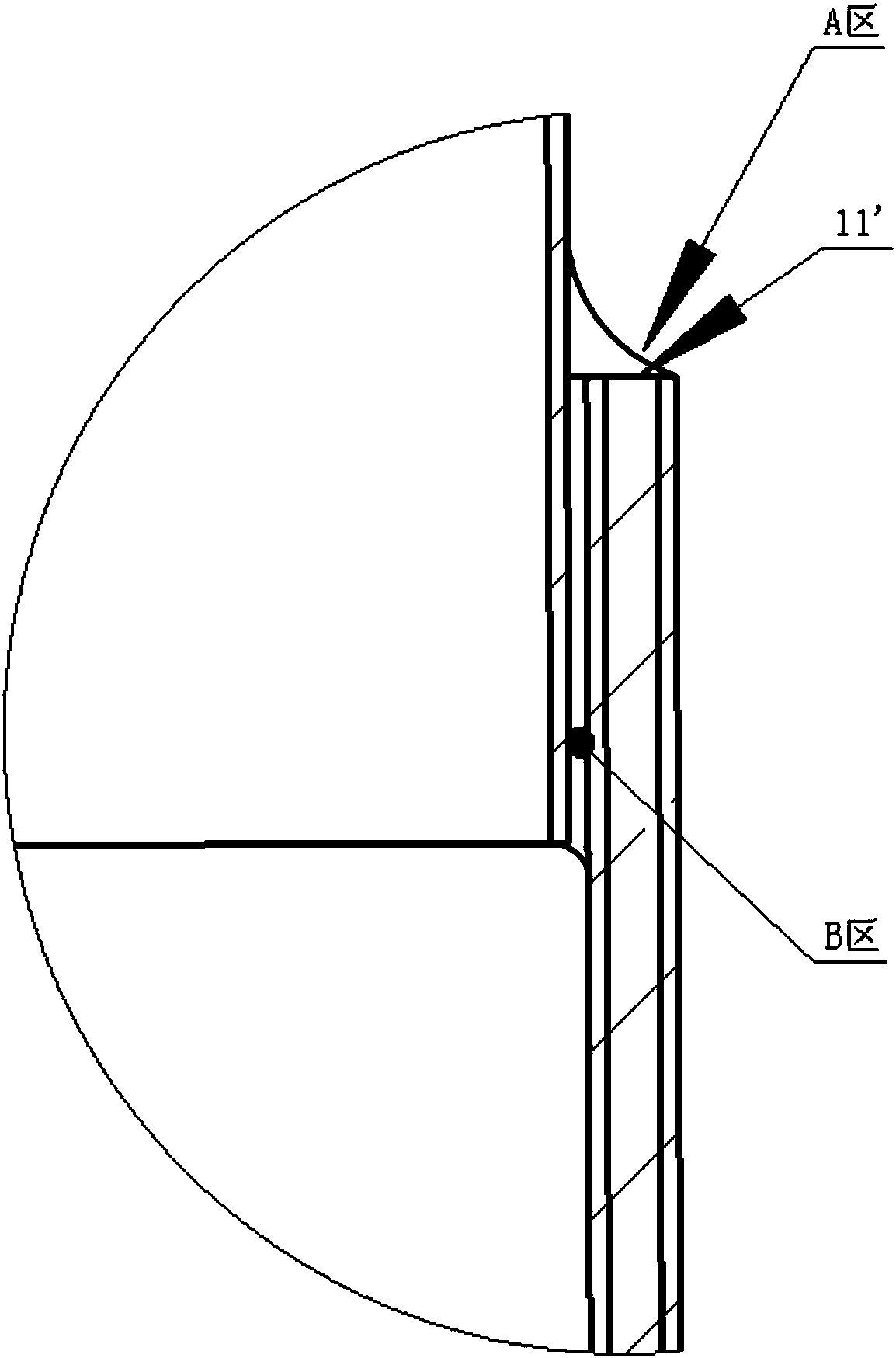

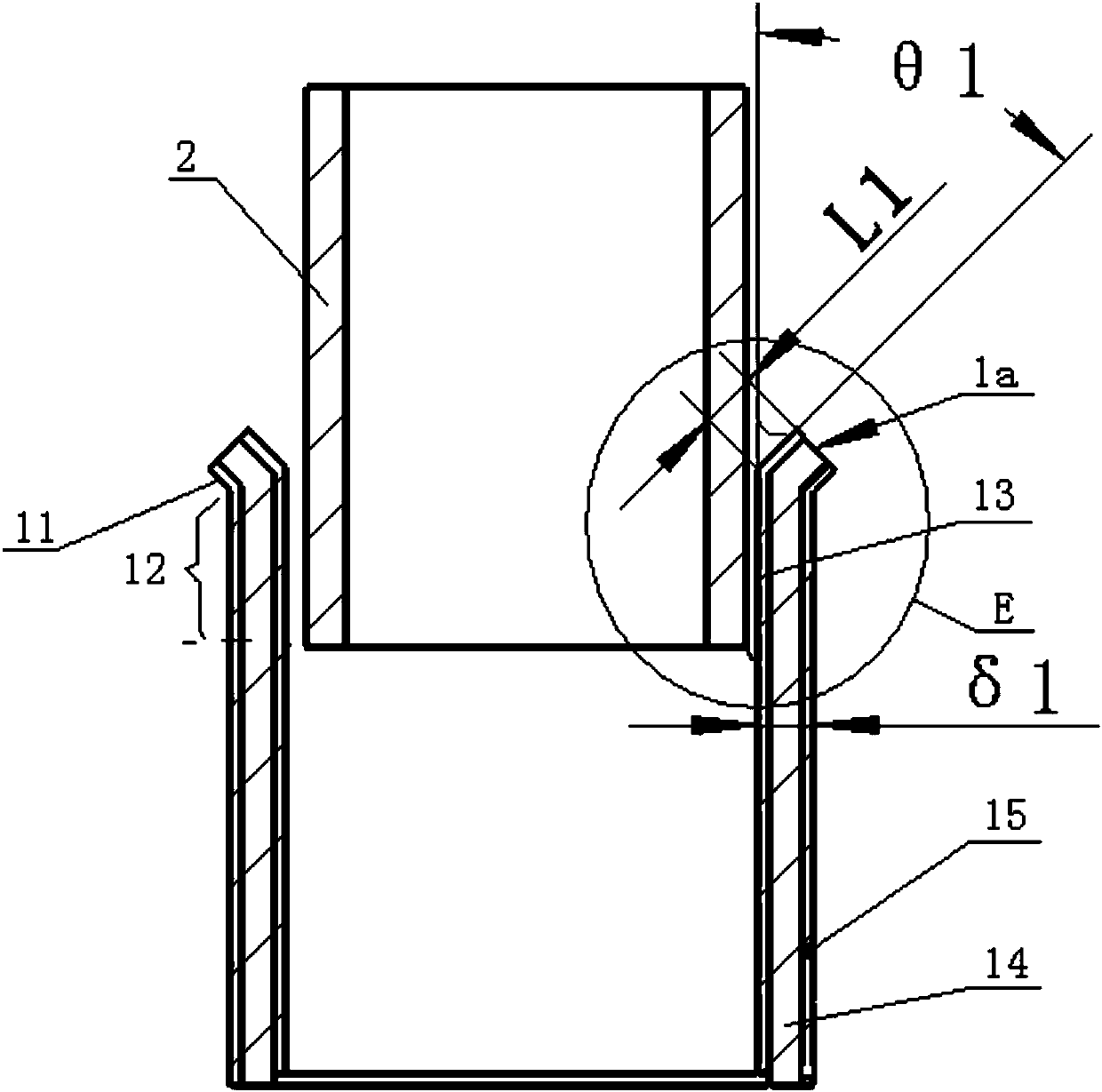

[0034] Aiming at the technical problem of poor performance of the copper-steel composite pipe welding section mentioned in the background technology, this paper conducts in-depth research. It is found that after the copper-steel composite pipe and copper pipe are welded, the solder is mainly distributed in two areas: The outer wall of the copper pipe and the end face of the steel-copper composite pipe ( figure 2 Middle A area) and the void space between the outer wall of the copper pipe and the inner wall of the copper-steel composite pipe and the root of the copper-steel ( figure 2 middle area B). The phosphor-copper solder located on the end face of the steel-copper composite pipe is in contact with the copper layer and the steel main body at the same time. Among them, the fluidity of the phosphor-copper solder on the surface of the steel material is relatively poor, and it is difficult to form a weld, resulting in the end face of the copper-steel composite pipe in area A....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com