Fiber stretching heating stage and small angle laser scattering instrument using fiber stretching heating stage

A laser scattering and fiber technology, which is applied in scattering characteristics measurement, instruments, scientific instruments, etc., can solve the problem of no fiber drawing hot stage, etc., and achieve the effects of high sensitivity, simple and convenient operation, and convenient crystallization induction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

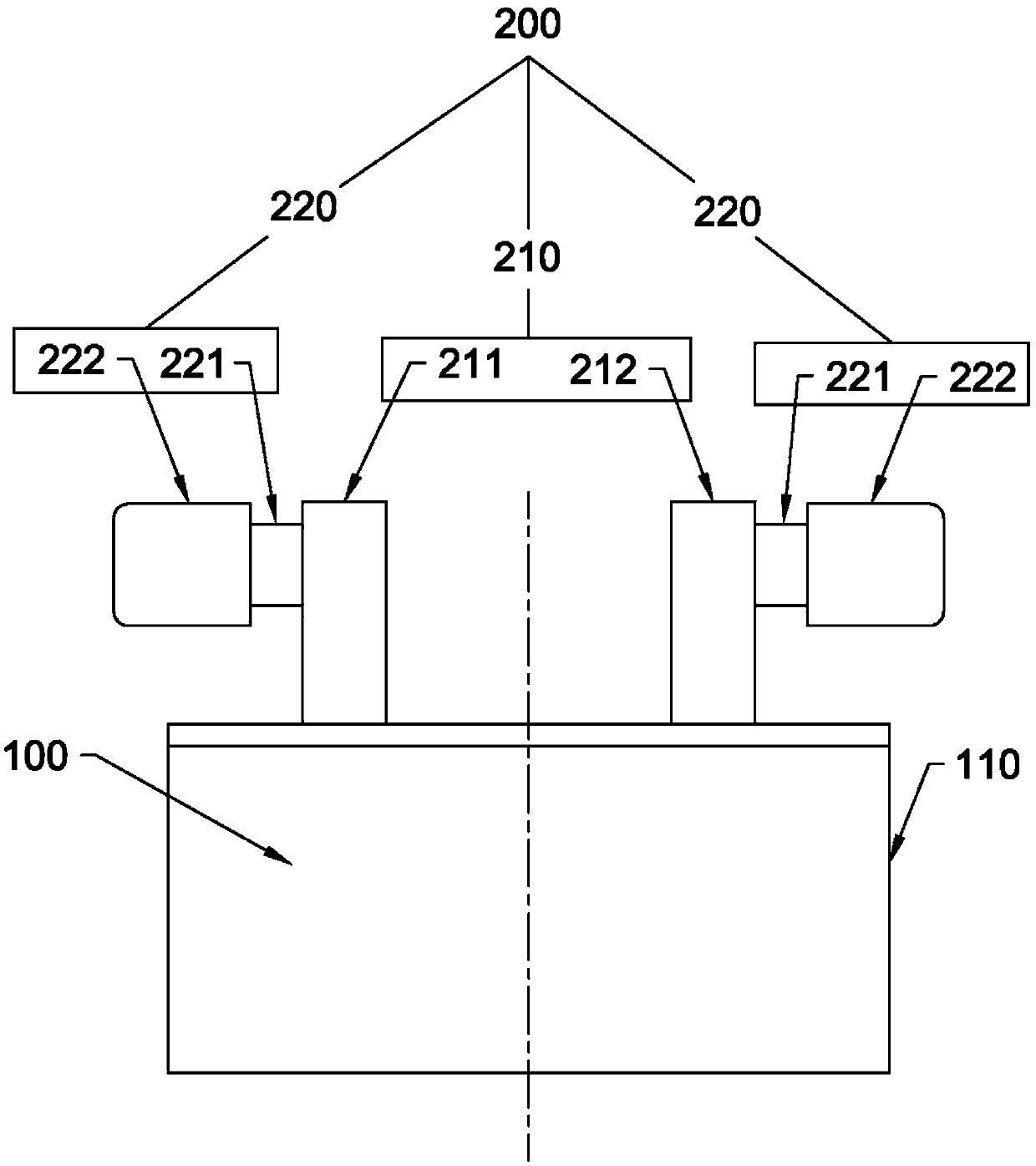

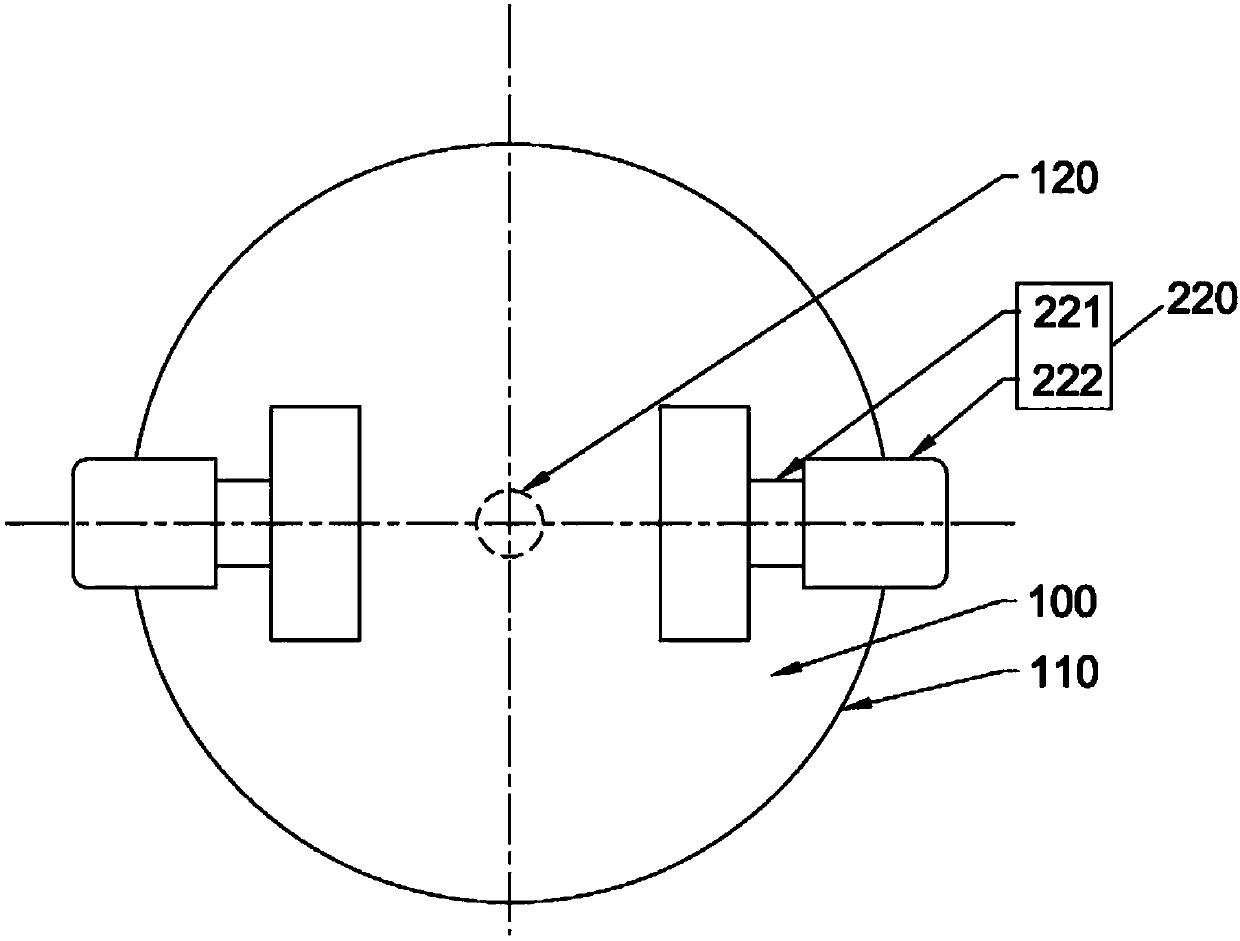

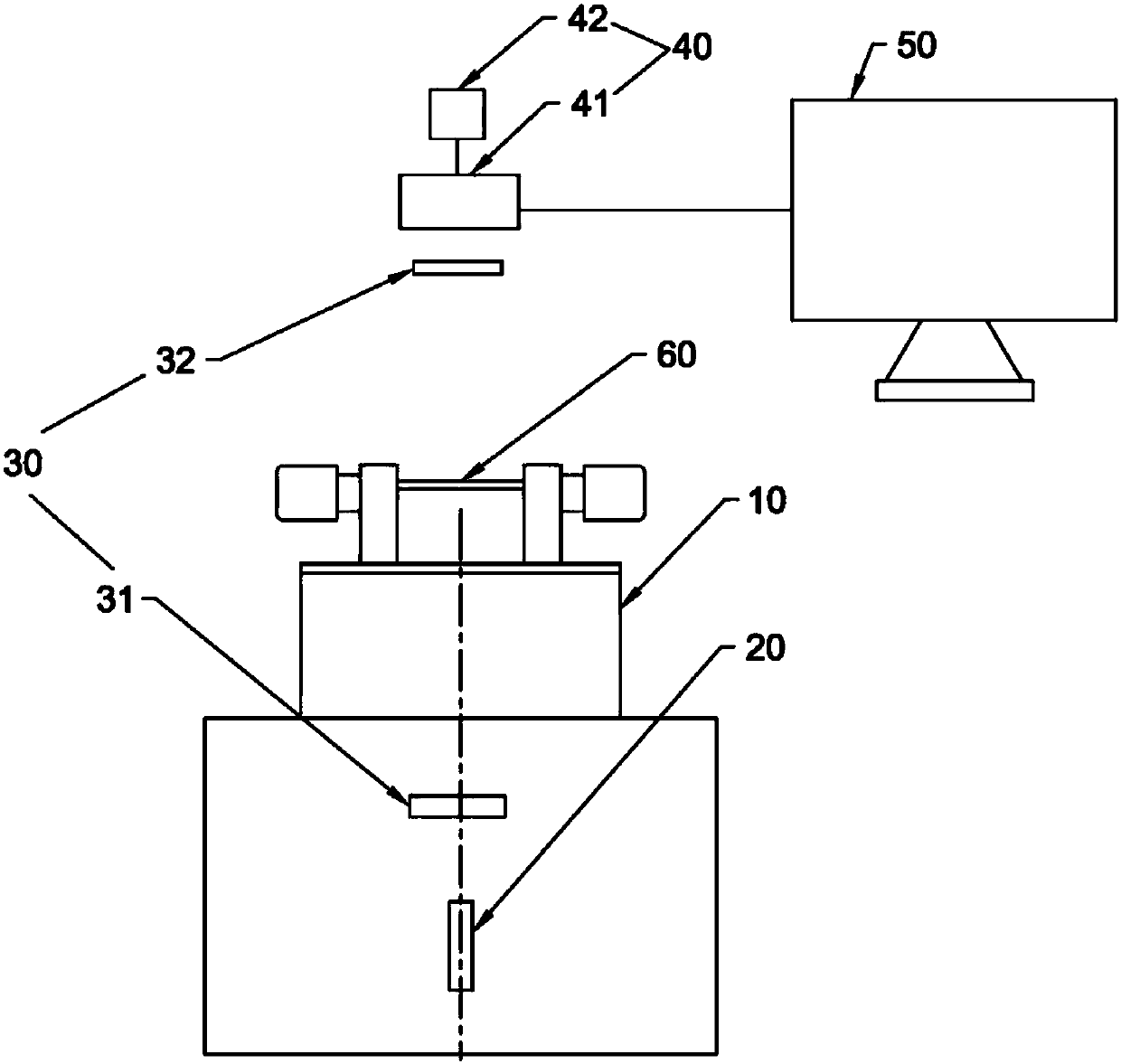

[0047] like figure 1 and figure 2As shown, the embodiment of the present invention provides a fiber drawing heat station, including a main body 100 and a mechanical drawing device 200 arranged on the main body 100 . The mechanical stretching device 200 includes a fixing unit 210 and an adjusting unit 220, the fixing unit 210 includes a first fixing end 211 and a second fixing end 212, and the two ends of the polymer fiber material sample are respectively fixed on the second fixing end. A fixed end 211 and a second fixed end 212, and the first fixed end 211 and / or the second fixed end 212 can move relatively along the line thereof, and the high polymer fiber material sample follows the first The relative movement of the fixed end 211 and / or the second fixed end 212 (when moving away) is stretched. The relative movement of the first fixed en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com