Continuous casting square billet corner defect automatic pre-warning system and method

An automatic early warning and defect technology, which is applied in the direction of optical testing flaws/defects, casting equipment, indicating equipment/measurement equipment configuration, etc., can solve the problems of early warning of defects in the corners of continuous casting billets, etc., to reduce the risk of occurrence, Effective and timely effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

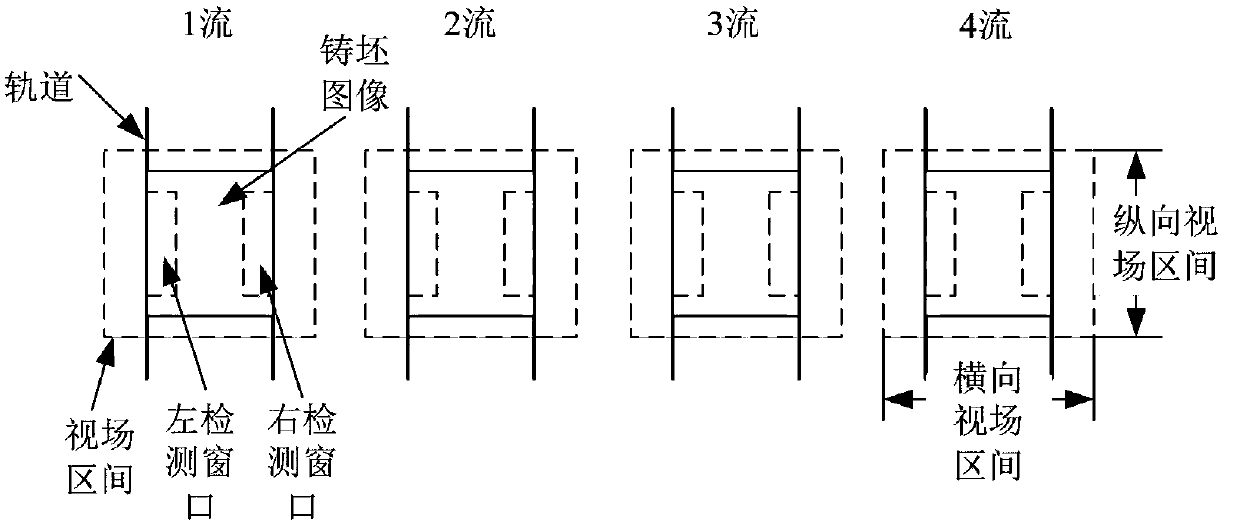

[0061] In this embodiment, the present invention is applied to Baosteel's four-strand bloom continuous casting machine, and the section of the billet of the continuous casting machine is 320*425mm. Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

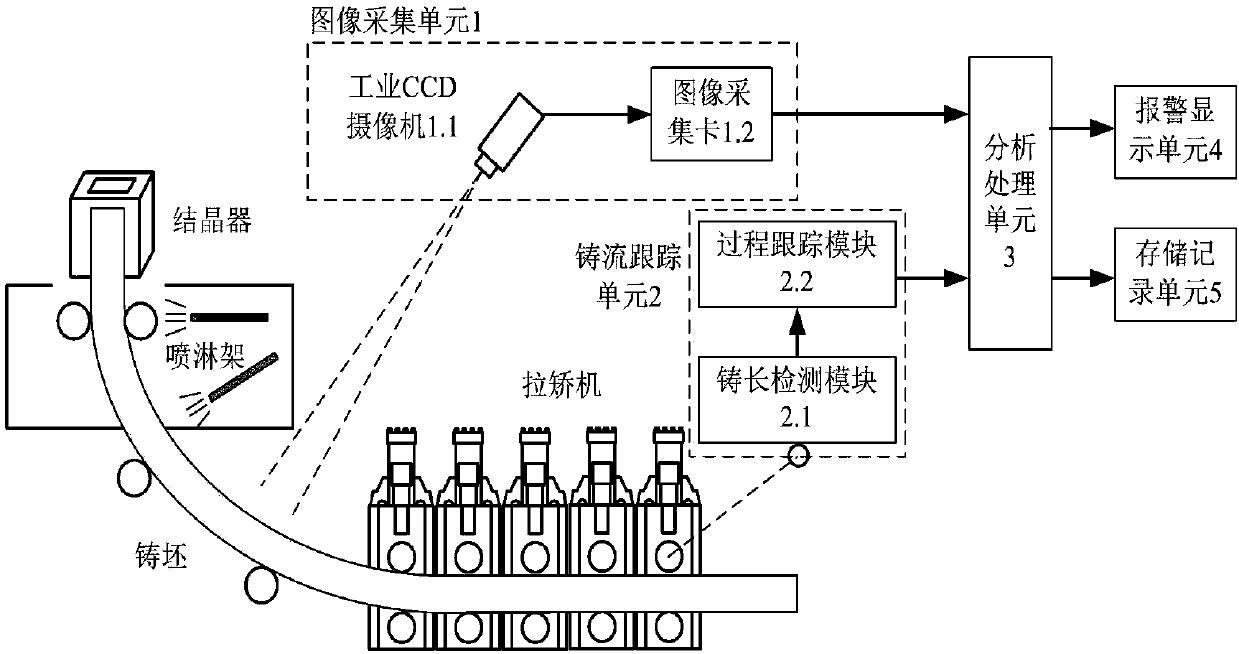

[0062] Such as figure 1 As shown, an automatic early warning system for corner defects of continuous casting billets includes an image acquisition unit 1 , a strand tracking unit 2 , an analysis and processing unit 3 , an alarm display unit 4 and a storage and recording unit 5 .

[0063] The image acquisition unit 1 includes an industrial CCD camera 1.1 and an image acquisition card 1.2; the industrial CCD camera 1.1 is equipped with a dustproof protective box with a window, and a three-dimensional adjustable pan-tilt bracket; the camera is contained in a dustproof protective box inside, fixed on the pan-tilt bracket, used to continuously collect images of high-temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com