Method for producing low aluminium silicon killed steel with converter by deoxidation of silicon alloy

A low-silicon-aluminum-killed steel and alloy technology, applied in the field of metallurgy, can solve the problems of large flocculation probability of the caster, high alloy cost, and large amount of aluminum alloy, so as to reduce the cost of deoxidized alloy, reduce the labor intensity of workers, and avoid The effect of production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] When the converter with a nominal volume of 100t produces low-silicon aluminum-killed steel, the tapping volume is 92t.

[0029] Use the following method to deoxidize the alloy in the converter, and at the same time change the original LF furnace treatment process so that the molten steel enters the station and is not killed, and the molten steel, especially the top slag, still has strong oxidation. After entering the LF furnace, blow argon and stir for 3 minutes to make the silicon component in the molten steel react with the FeO in the top slag. It can achieve the effect of reducing the risk of flocculation in the casting machine, reducing the cost of deoxidized alloy, and reducing the quality risk.

[0030] The method for producing low-silicon aluminum-killed steel by deoxidation of silicon-based alloys is as follows:

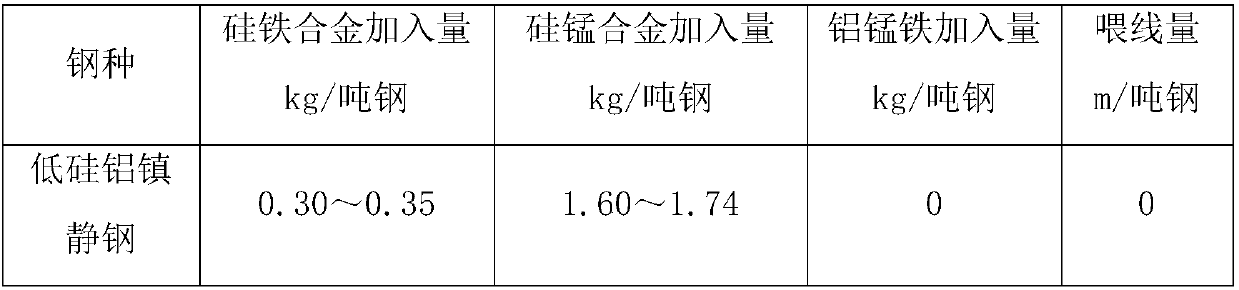

[0031] (1) Only silicon-based alloys are added to the converter, and the amount of alloys added is shown in Table 3;

[0032] table 3:

[0033] ...

Embodiment 2

[0048] When a converter with a nominal volume of 150t produces low-silicon aluminum-killed steel, the tapping volume is 132t.

[0049] Use the following method to deoxidize the alloy in the converter, and at the same time change the original LF furnace treatment process so that the molten steel enters the station and is not killed, and the molten steel, especially the top slag, still has strong oxidation. After entering the LF furnace, blow argon and stir for 3 minutes to make the silicon component in the molten steel react with the FeO in the top slag. It can achieve the effect of reducing the risk of flocculation in the casting machine, reducing the cost of deoxidized alloy, and reducing the quality risk.

[0050] The method for producing low-silicon aluminum-killed steel by deoxidation of silicon-based alloys is as follows:

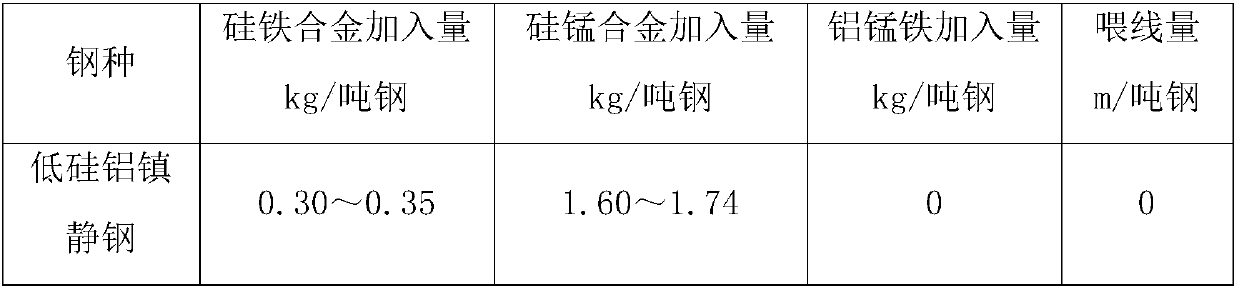

[0051] (1) Only silicon-based alloys are added to the converter, and the amount of alloys added is shown in Table 5;

[0052] table 5:

[0053] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com