Three-dimensional structure sulfur copper compound/carbon fiber composite material, its preparation method and application

A composite material and three-dimensional structure technology, applied in the manufacture of hybrid/electric double layer capacitors, nanotechnology for materials and surface science, hybrid capacitor electrodes, etc., can solve the problem that the electrochemical activity has not been substantially improved, the copper sulfide ratio Problems such as small surface area and low active material loading can achieve the effects of easy large-scale implementation, high production efficiency, and improved electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] First, about 2 mmol of CuCl 2 2H 2 O was stirred in 5 ml of dimethyl diamide (DMF) until dissolved, then about 1 g of polyacrylonitrile (PAN) was added and stirred for 12 hours to obtain a uniform spinning solution.

[0063] Build the electrospinning equipment, use DC high-voltage power supply, use aluminum foil as the collector and 5ml needle tube as the spinning generator, put the aforementioned spinning solution into the needle tube, introduce one pole of the DC power supply; connect the other pole to the collection device Aluminum foil, start electrospinning, select voltage 8-16Kv, flow rate 1-3ml / h, collector distance from spinning generator 8-16cm, temperature and humidity controlled at 25-40°C and 30-45%, to obtain spinning material .

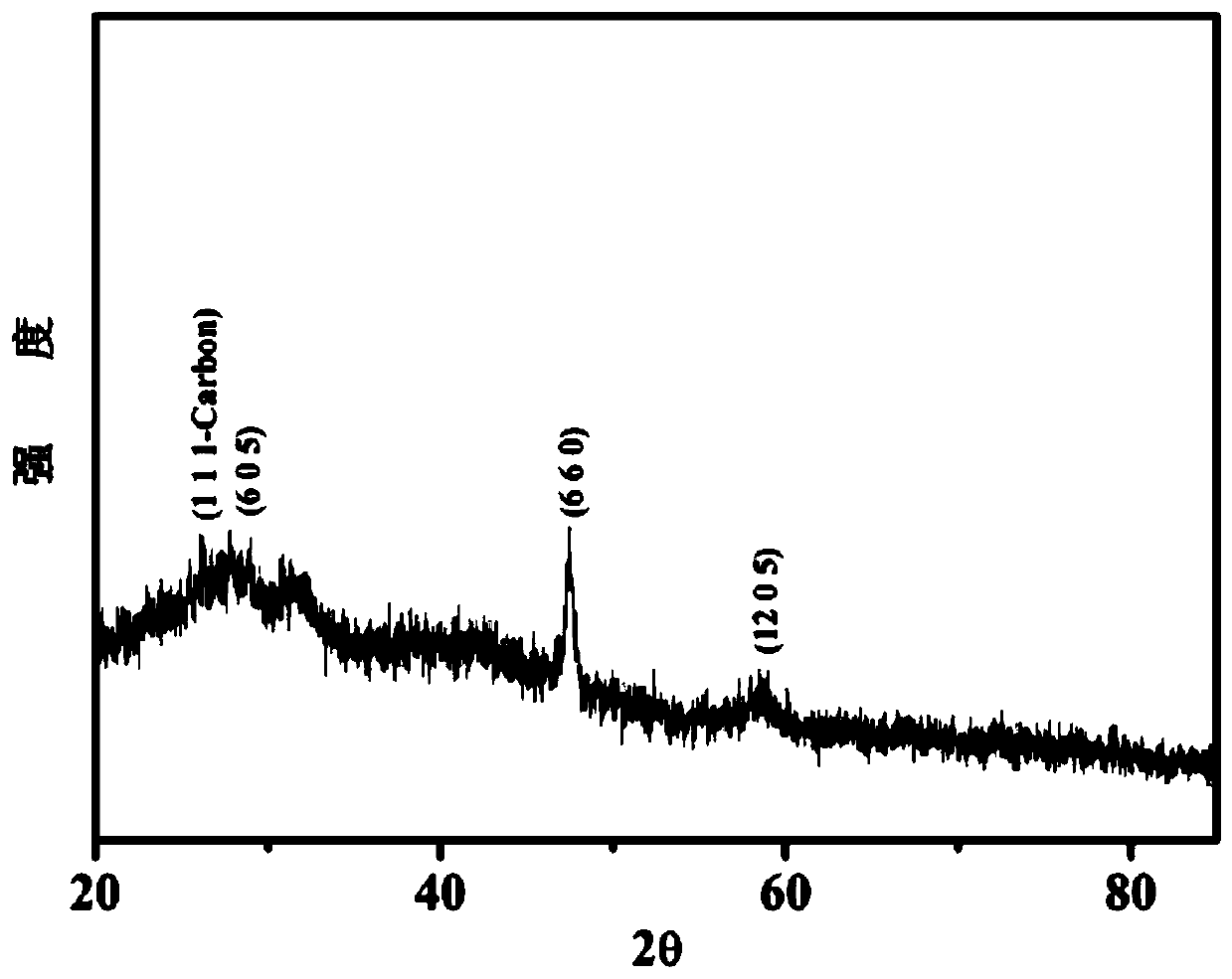

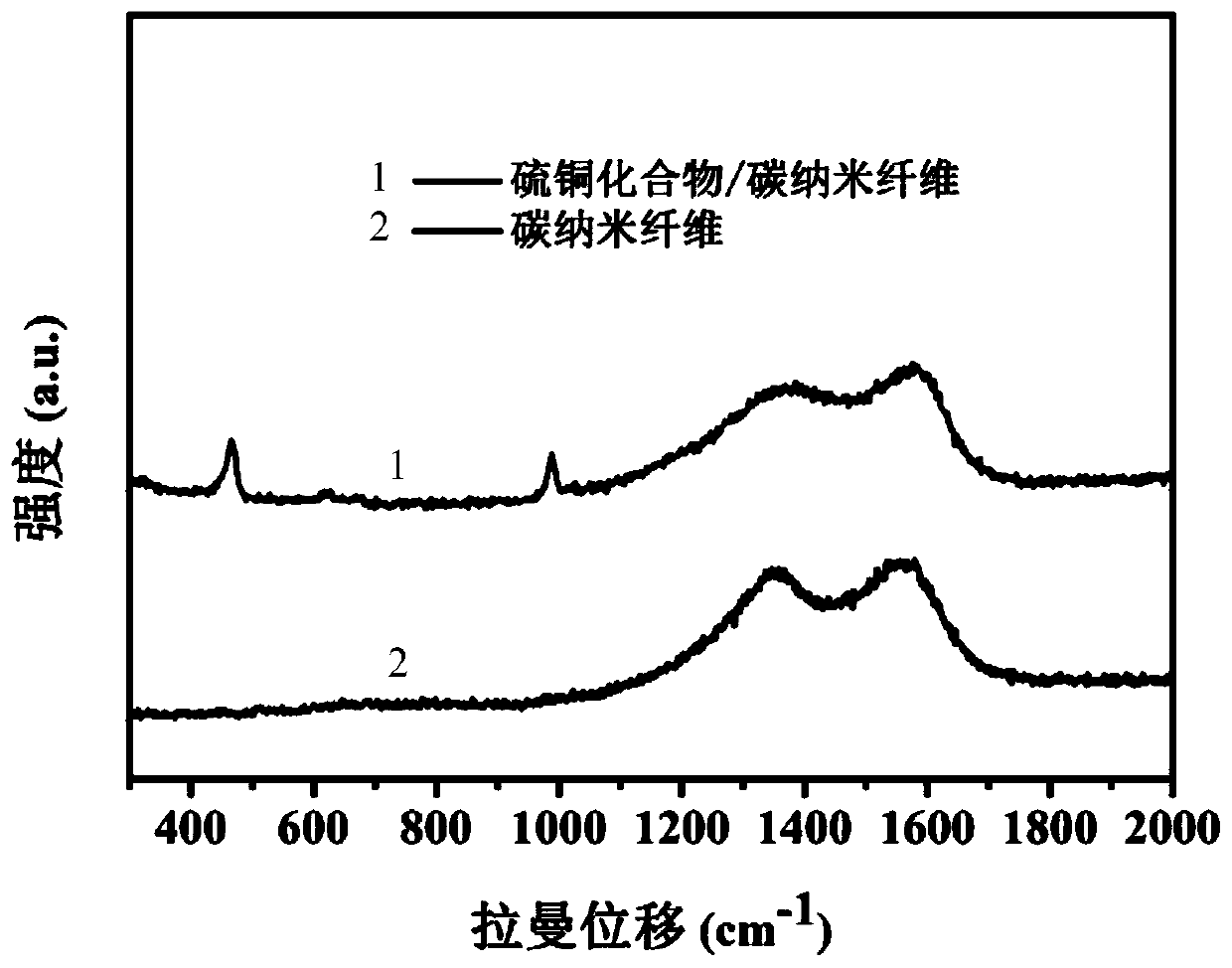

[0064] The obtained spinning material is wrapped in aluminum foil in a muffle furnace and calcined in air at 250-260°C for 1-3 hours, and then calcined in a tube furnace at 600-650°C under argon for 1-3 hours to obtain a precurs...

Embodiment 2

[0066] First add 1.5mmol of CuSO 4 ·5H 2 O was stirred in 6 ml of dimethyl diamide (DMF) until dissolved, then 1 g of polyacrylonitrile (PAN) was added and stirred for 12 hours to obtain a uniform spinning solution.

[0067] Build the electrospinning equipment, use a DC high-voltage power supply, use an aluminum foil collector and a 5ml needle tube as the spinning generation device, put the aforementioned spinning solution into the needle tube, introduce one pole of the DC power supply; connect the other pole to the collection device Aluminum foil, start electrospinning, select voltage 6-16Kv, flow rate 1-3ml / h, collector 8-16cm away from spinning generator, temperature and humidity controlled at 20-40°C and 30-45%, to obtain spinning material .

[0068] Wrap the above-mentioned spinning material with aluminum foil in a muffle furnace and calcinate it in the air at 270-280°C for 1-3 hours, and then calcinate it in a tube furnace at 700-750°C under argon for 1-3 hours to obta...

Embodiment 3

[0070] First, 2.5mmol of Cu(CH 3 COO) 2 Stir in 5 ml of dimethyl diamide (DMF) until dissolved, then add 1 g of polyacrylonitrile (PAN) and stir for 12 hours to obtain a uniform spinning solution.

[0071] Build the electrospinning equipment, use a DC high-voltage power supply, use an aluminum foil collector and a 5ml needle tube as the spinning generation device, put the aforementioned spinning solution into the needle tube, introduce one pole of the DC power supply; connect the other pole to the collection device Aluminum foil, start electrospinning, choose a voltage of 6-16Kv, a flow rate of 1-3ml / h, the collector is 8-16cm away from the spinning generator, and the temperature and humidity are controlled at 25-40°C and 30-45%. The obtained material is wrapped in aluminum foil in a muffle furnace and calcined in the air at 260-270°C for 1-3 hours, and then calcined in a tube furnace at 750-800°C under argon for 1-3 hours to obtain a precursor material, which is cut into a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com