Method for preparing grooved gate of transistor and high-power radio frequency device

A groove gate and transistor technology, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of low resolution of stepper projection lithography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the technical solution of the present invention, a method for preparing a groove gate of a transistor and a high-power radio frequency device provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. In the drawings, the thicknesses of layers and regions are exaggerated for device clarity, and the same reference numerals are used to refer to the same elements throughout the specification and drawings.

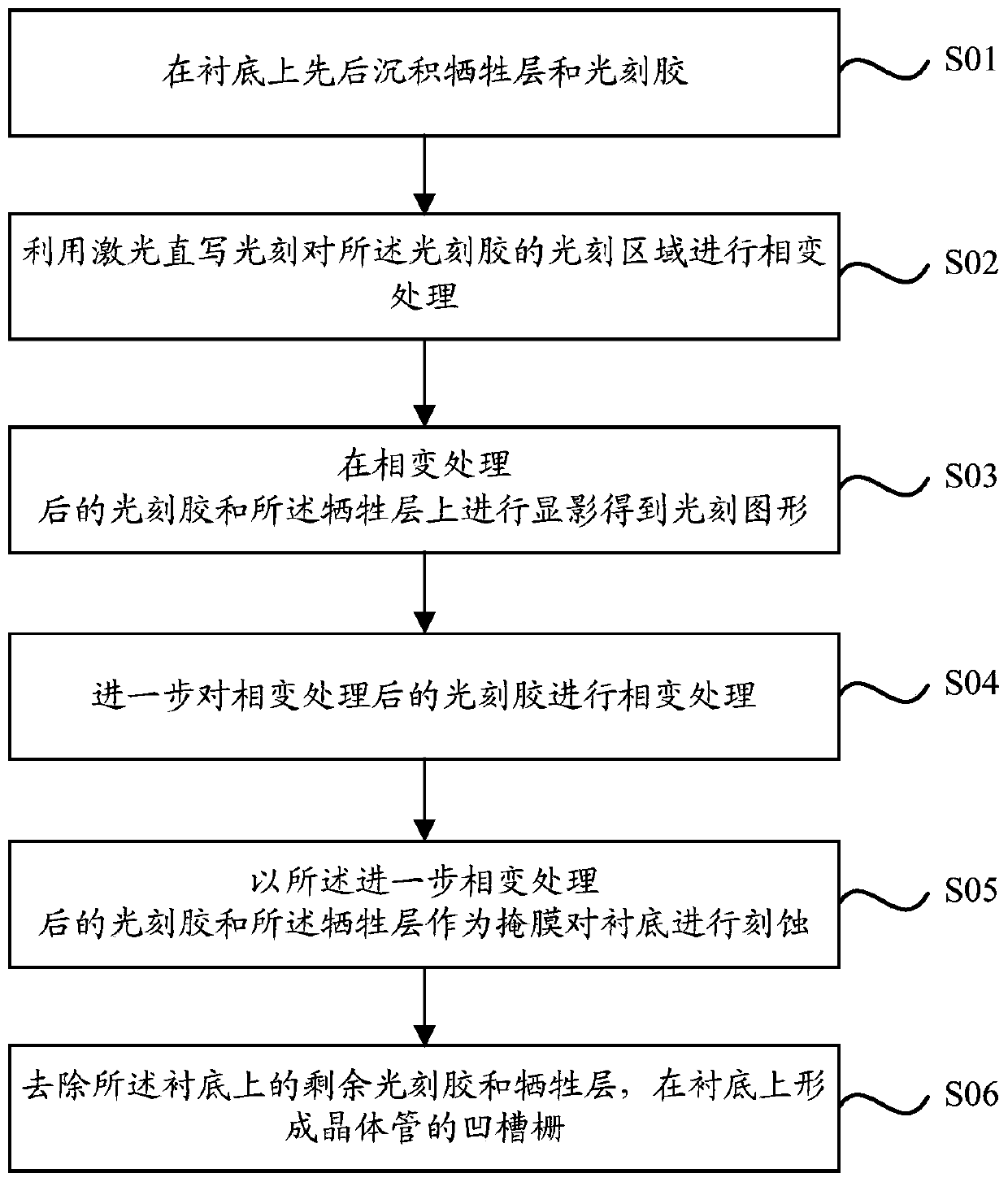

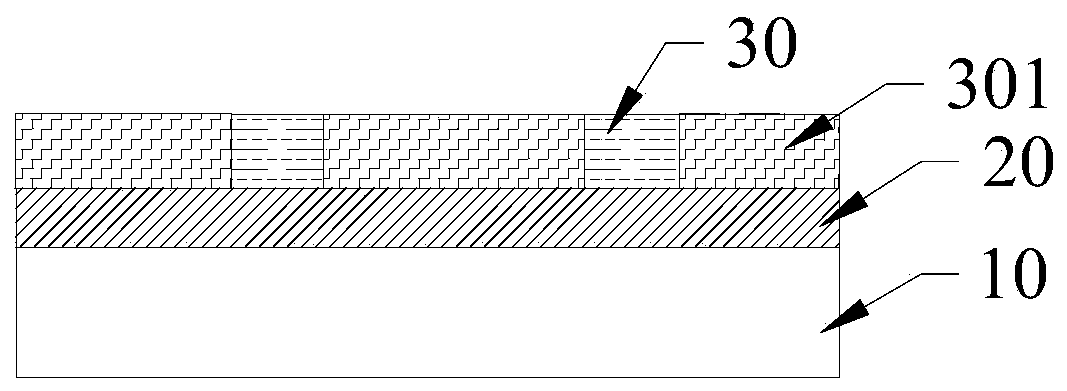

[0038] refer to figure 1 , an embodiment of the preparation method of the groove gate of the transistor of the present invention includes the following steps:

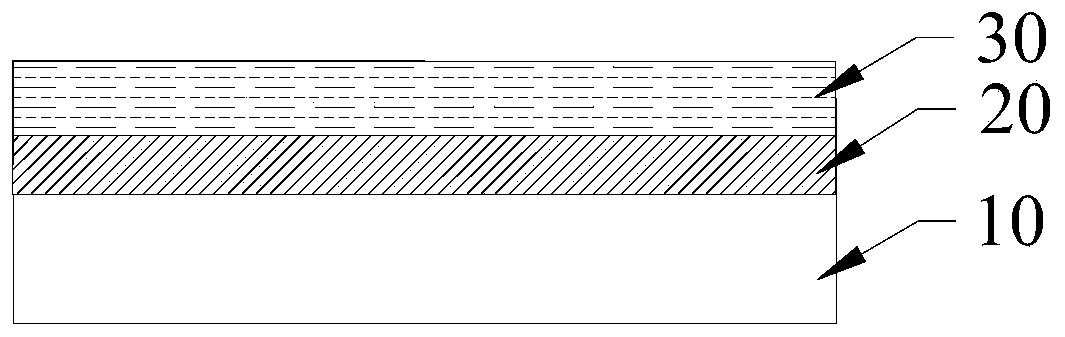

[0039] S01. Depositing a sacrificial layer and a photoresist successively on the substrate.

[0040] Using gallium nitride (GaN) as the substrate, the GaN substrate is deposited by atomic layer deposition, plasma enhanced chemical vapor deposition, electricall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com