A kind of processing technology of foamer foam cover

A processing technology and foamer technology, which is applied in the field of processing technology of the foaming cover of the foamer, can solve the problems of low mechanical properties and achieve the effect of improving mechanical properties and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

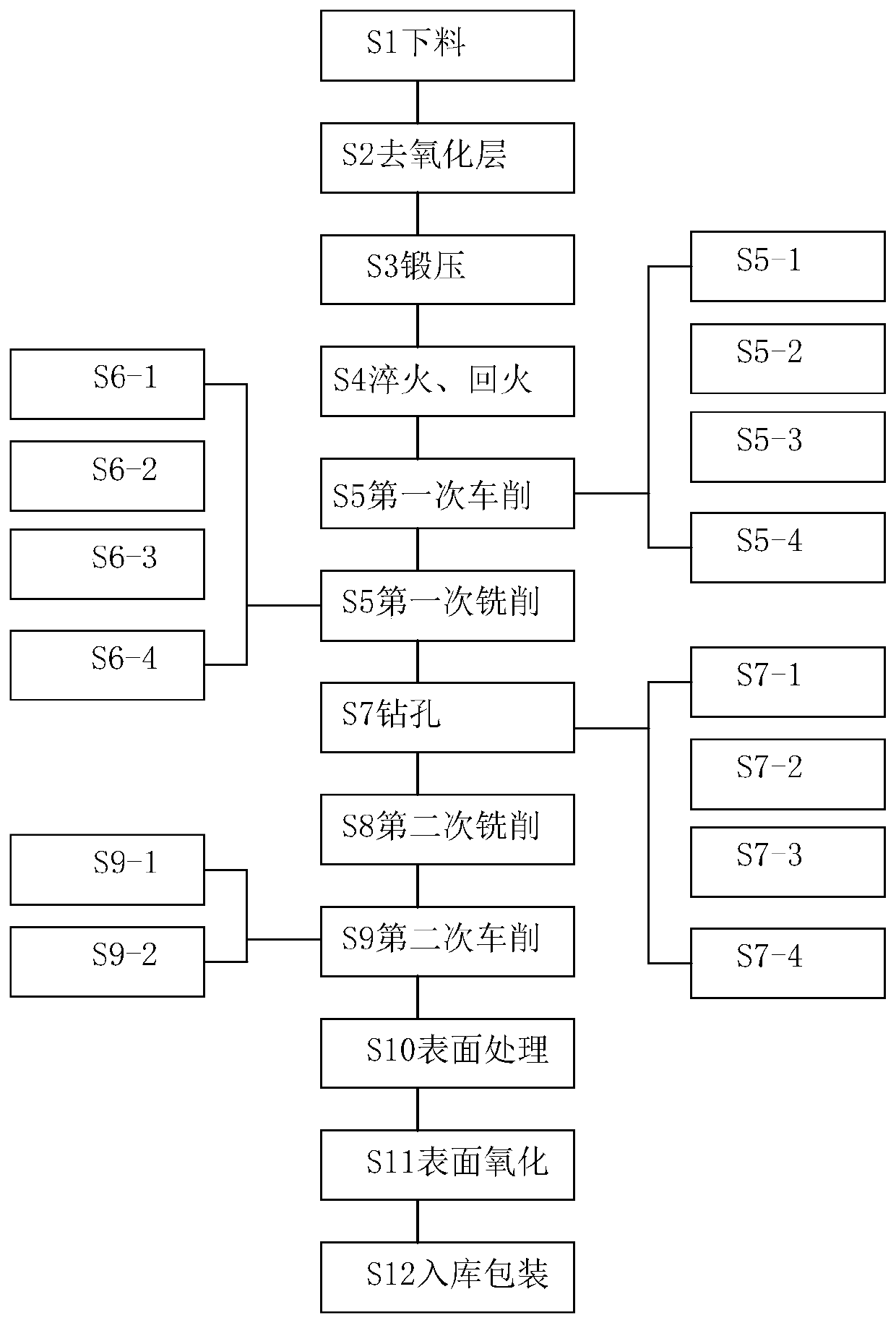

[0041] Such as figure 1 As shown, this embodiment includes the following specific steps:

[0042] S1: Cutting: Select the aluminum rod raw material corresponding to the size to cut and cut according to the size and length, and obtain the cut cylindrical blank.

[0043] S2: Deoxidation layer: Clamp the cylindrical blank in the above S1 into a lathe, and turn the outer circular surface and both ends of the cylindrical blank to remove the surface oxide layer of the bar.

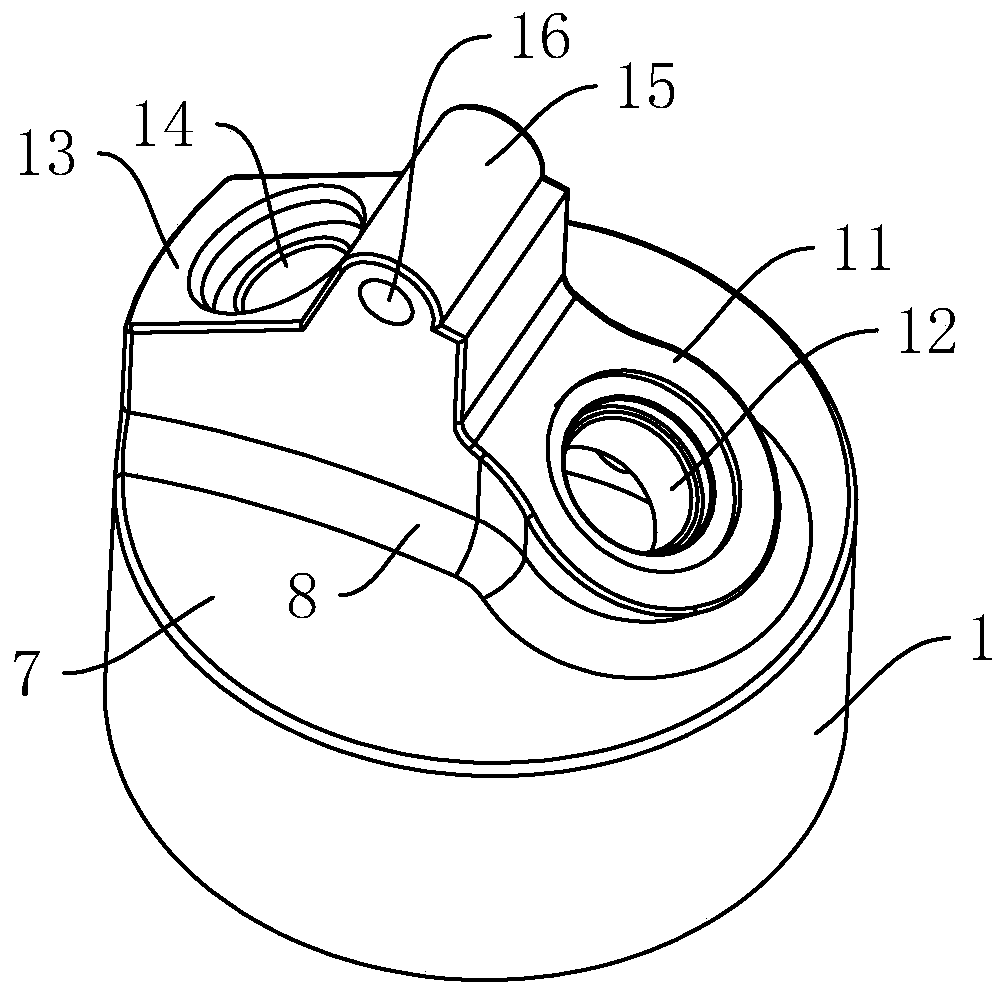

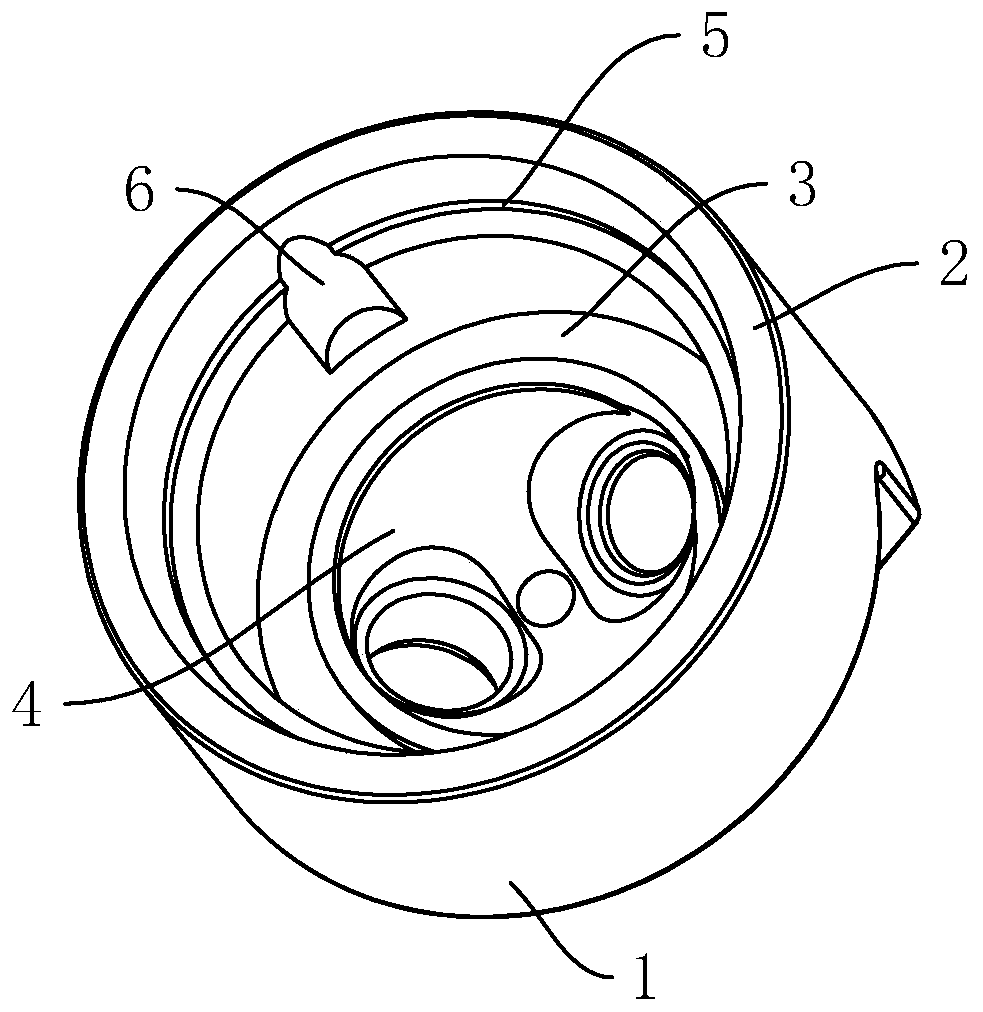

[0044] S3: forging, first place the cylindrical blank with the oxide layer removed in a heating furnace and heat it to 400°C for a period of time, then put it into a forging mold for forging and pressing, forming a ridge 8 on the top and a first cylinder 9 and the forging blank of the second cylinder 10, the forging blank includes a cylindrical body 1, a ridge 8 that is convexly arranged on the top end surface of the cylindrical body 1, and a ridge 8 that is concavely arranged at the other end of the cylindrica...

Embodiment 2

[0071] Such as figure 1 As shown, this embodiment includes the following specific steps:

[0072] S1: Cutting: Select the aluminum rod raw material corresponding to the size to cut and cut according to the size and length, and obtain the cut cylindrical blank.

[0073] S2: Deoxidation layer: Clamp the cylindrical blank in the above S1 into a lathe, and turn the outer circular surface and both ends of the cylindrical blank to remove the surface oxide layer of the bar.

[0074] S3: forging, first place the cylindrical blank with the oxide layer removed in a heating furnace and heat it to 400°C for a period of time, then put it into a forging mold for forging and pressing, forming a ridge 8 on the top and a first cylinder 9 and the forging blank of the second cylinder 10, the forging blank includes a cylindrical body 1, a ridge 8 that is convexly arranged on the top end surface of the cylindrical body 1, and a ridge 8 that is concavely arranged at the other end of the cylindrica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com