Automatic truck loading system for gravel

A sand and gravel automatic technology, which is applied in the field of sand and gravel loading control and automatic sand and gravel loading system, can solve the problems of no alarm device, inability to apply to roads and mines, and complex configuration, so as to reduce costs, facilitate maintenance and running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

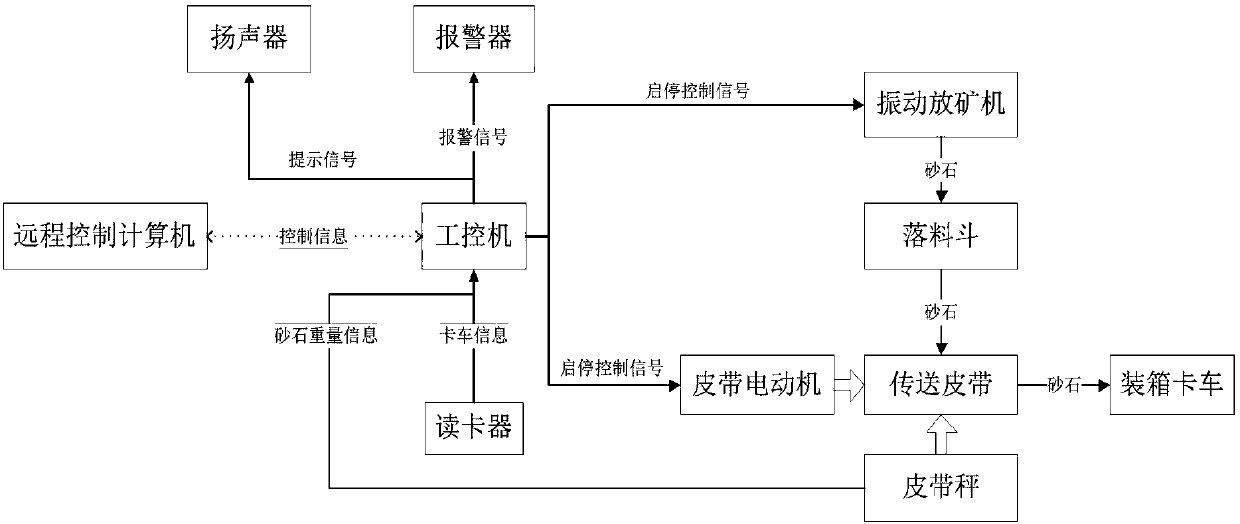

[0018] Such as figure 1 As shown, an automatic sand and gravel loading system is characterized in that it includes an industrial computer, a conveyor belt, a vibrating ore feeding machine, a hopper, and a belt motor. The power output shaft of the belt motor is connected to the conveyor belt to provide power for the conveyor belt. The industrial computer is connected with the vibrating ore-drawing machine and the belt motor; the dropping hopper is arranged at the exit of the vibrating ore-drawing machine, and the lower end of the dropping hopper is placed above the transmission belt.

[0019] When the industrial computer is working, it sends a start-stop control signal to the vibrating ore feeding machine and the belt motor to control its work. When starting, the industrial computer first starts the belt motor to work, and then turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com