Self-compacting road backfill material produced by using sawed stone mud and construction method of self-compacting road backfill material

A self-compacting, stone technology, applied in filling, building and other directions, can solve the problems of complex production technology, not very broad application area, high production cost, and achieve the effect of wide application range, wide application range and simple construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

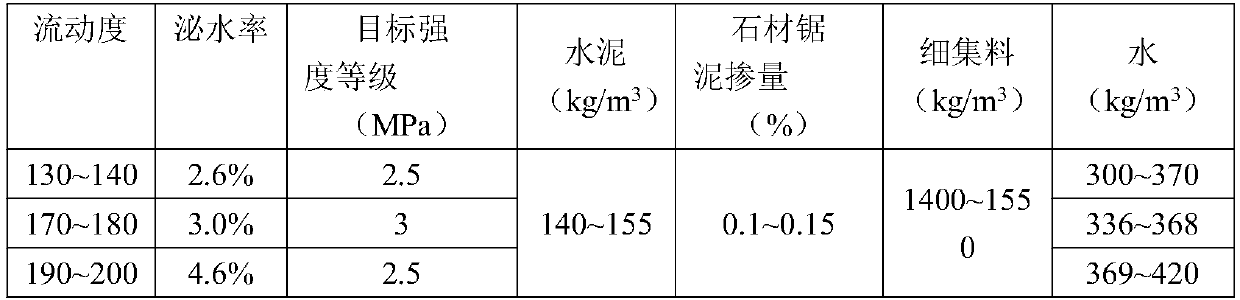

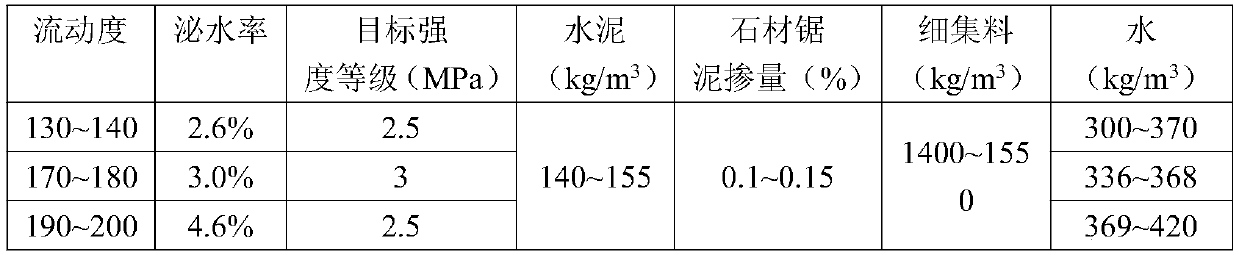

[0059] The non-motor vehicle lane of a city road collapsed, because the space was narrow, and large compaction machines could not be used for compaction. Adopt the road backfill material that utilizes the stone material sawn mud production provided by the present invention to carry out backfill, the specific implementation method is as follows:

[0060] Construction materials: The cement used is Diamond PC42.5R composite Portland cement; the backfill fine material is machine-made sand, and the stone sawn mud is taken from the open-air storage yard with a moisture content of 0.6%; the water is potable tap water.

[0061] construction process:

[0062] 1. Clean up the debris, garbage and other sundries around the drainage well.

[0063] 2. Determine the construction mix ratio. Cement 146kg / m 3 , stone sawing mud 219kg / m 3 , machine-made sand 1462kg / m 3 , water 328kg / m 3 .

[0064] 3. On-site mixing. A small concrete mixer is used to mix stone sawn mud road backfill mater...

Embodiment 2

[0069] The surrounding area of a road drainage well in a certain city has subsided. Due to the narrow space, large compaction machines cannot be used for compaction. Adopt the road backfill material that utilizes the stone material sawn mud production provided by the present invention to carry out backfill, the specific implementation method is as follows:

[0070] Construction materials: the cement used is Drill brand PC32.5R composite Portland cement; the backfill fine material is construction waste fine aggregate with a moisture content of 0.06%; Drinkable tap water.

[0071] construction process:

[0072] 1. Clean up the debris, garbage and other sundries around the drainage well.

[0073] 2. Determine the construction mix ratio. Cement 145kg / m 3 , stone sawing mud 290kg / m 3 , construction waste recycled coarse material 1449kg / m 3 , water 527kg / m 3 .

[0074] 3. On-site mixing. A small concrete mixer is used to mix stone sawn mud road backfill materials, and the...

Embodiment example 3

[0079] The backfilling construction of the bridge and culvert platform back of a certain expressway has a narrow space, and the compacting equipment cannot enter. The road backfilling material produced by utilizing stone sawn mud provided by the present invention is adopted, and the specific implementation method is as follows:

[0080] Construction materials: the cement used is Drill brand PC42.5R composite portland cement; the backfill fine material is construction waste fine material with a moisture content of 0.5%; the stone sawn mud is taken from an open storage yard with a moisture content of 0.6%; water is Drinkable tap water.

[0081] construction process:

[0082] 1. Clean up the debris, garbage and other debris around the back of the bridge and culvert abutment.

[0083] 2. Determine the construction mix ratio. Cement 143kg / m 3 , stone sawing mud 214kg / m 3 , machine-made sand 1425kg / m 3 , water 374kg / m 3 .

[0084] 3. On-site mixing. A small concrete mixer is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Liquidity | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com