Fireproof rubber of fireproof glass and preparation method thereof

A fireproof glass and fireproof glue technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of insufficient fireproof glue layer hardness, affecting the use effect and life of fireproof glass, etc., and achieve long fireproof time. , The effect of eliminating bubbles and high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

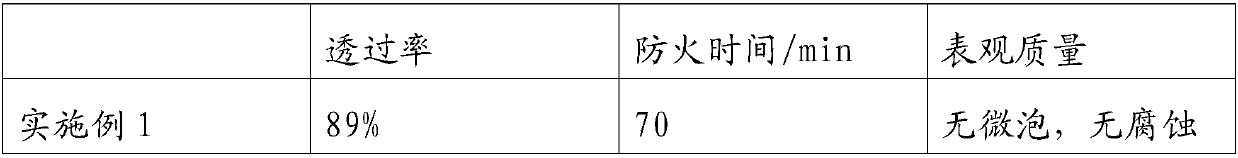

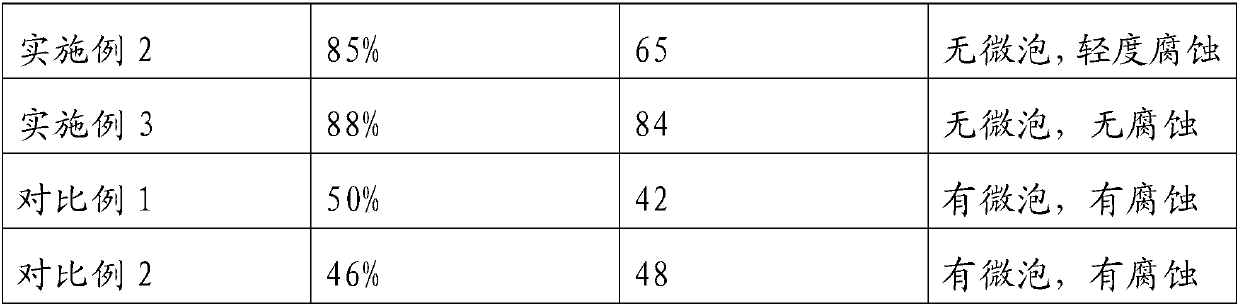

Examples

Embodiment 1

[0015] A fireproof glue for fireproof glass of the present embodiment comprises the following raw materials in parts by weight: 20 parts of silicone rubber, 50 parts of water glass, 5 parts of dimethyl silicone oil, 4 parts of kaolin, 4 parts of acrylamide, 6 parts of hydrogen oxide Aluminum, 2 parts of hydroxymethyl cellulose, 5 parts of sodium hexametaphosphate, 5 parts of glycerin, 2 parts of coupling agent.

[0016] The fireproof glue of this embodiment can eliminate air bubbles in the composite fireproof glass interlayer by utilizing the synergistic effect among the various components, and can prepare composite fireproof glass with high transmittance and long fireproof time.

[0017] The preparation method of the fireproof glue of the present embodiment may further comprise the steps:

[0018] (1) Take the above-mentioned raw materials by weight, add water glass in the reaction kettle, stir at a constant speed and heat up to 90°C, add silicone rubber and dimethyl silicone...

Embodiment 2

[0023] A fireproof glue for fireproof glass of the present embodiment comprises the following raw materials in parts by weight: 30 parts of silicone rubber, 60 parts of water glass, 8 parts of dimethyl silicone oil, 5 parts of kaolin, 8 parts of acrylamide, 7 parts of hydrogen hydroxide Aluminum, 3 parts of hydroxymethylcellulose, 6 parts of sodium hexametaphosphate, 7 parts of glycerin, and 3 parts of coupling agent.

[0024] The fireproof glue of this embodiment can eliminate air bubbles in the composite fireproof glass interlayer by utilizing the synergistic effect among the various components, and can prepare composite fireproof glass with high transmittance and long fireproof time.

[0025] The preparation method of the fireproof glue of the present embodiment may further comprise the steps:

[0026] (1) Take the above-mentioned raw materials by weight, add water glass in the reaction kettle, stir at a constant speed and heat up to 95°C, add silicone rubber and dimethyl s...

Embodiment 3

[0031] A fireproof glue for fireproof glass of the present embodiment comprises the following raw materials in parts by weight: 40 parts of silicone rubber, 70 parts of water glass, 10 parts of dimethyl silicone oil, 6 parts of kaolin, 10 parts of acrylamide, 10 parts of hydrogen hydroxide Aluminum, 5 parts of hydroxymethylcellulose, 8 parts of sodium hexametaphosphate, 8 parts of glycerin, and 5 parts of coupling agent.

[0032] The fireproof glue of this embodiment can eliminate air bubbles in the composite fireproof glass interlayer by utilizing the synergistic effect among the various components, and can prepare composite fireproof glass with high transmittance and long fireproof time.

[0033] The preparation method of the fireproof glue of the present embodiment may further comprise the steps:

[0034] (1) Take the raw materials of the above weight parts, add water glass in the reaction kettle, stir at a constant speed and heat up to 100 ° C, add silicone rubber and dime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com