A high-strength, excellent low-temperature toughness marine steel and its multi-stage heat treatment process for a steel

A low-temperature toughness, marine steel technology, applied in the field of metallurgy, can solve the problems of high alloy cost, different alloy composition schemes, complex production process, etc., and achieve the effects of reducing energy consumption, shortening production cycle, and wide process adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The steel plate thickness of this embodiment is 42mm, and its chemical composition is C 0.13%, Si 0.20%, Mn 1.45%, Ni 0.12%, Cr 0.16%, Mo 0.08%, Nb 0.023%, Ti 0.014%, V≤ 0.02%, P≤0.015%, S≤0.0022%, B 0.002% and the balance Fe.

[0020] Manufacture steel slabs according to the above composition, heat the steel slabs to 1050-1150°C, control rolling to a specified thickness, air-cool to room temperature after rolling, and then conduct heat treatment. Samples are taken on finished marine steel plates, and then tensile and low temperature impact tests are performed.

[0021] The heat treatment process of the test steel is as follows:

[0022] (1) Sub-temperature quenching: Heat the test steel to 820°C, keep it warm for 50min, and then water-cool to room temperature.

[0023] (2) Tempering: Heat the sample that has been quenched and cooled to room temperature to 635°C, keep it warm for 60min, and then take it out and cool it in air.

[0024] After the above treatment, the ...

Embodiment 2

[0026] The thickness of the steel plate in this embodiment is 27 mm, and its chemical composition is the same as that in Embodiment 1.

[0027] The heat treatment process of the test steel is as follows:

[0028] (1) Sub-temperature quenching: Heat the test steel to 790°C, keep it warm for 35min, and then water-cool to room temperature.

[0029] (2) Tempering: Heat the sample that has been quenched and cooled to room temperature to 600°C, keep it warm for 45 minutes, and then take it out and air-cool it.

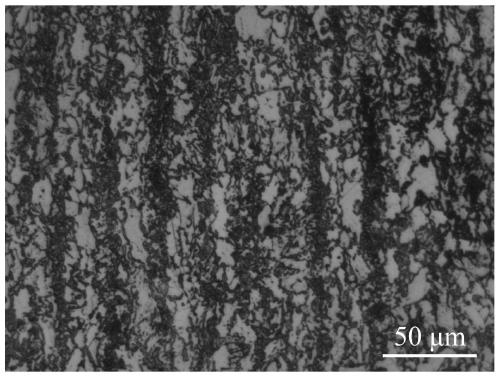

[0030] After the above treatment, the tempered tissue such as figure 1 As shown, it is ferrite + tempered sorbite, and the volume fraction of ferrite is 32%. The yield strength of the test steel is 521MPa, the tensile strength is 615MPa, the elongation is 22.60%, and the impact energy absorbed at -40°C is 218 / 216 / 215J respectively, which can meet the requirements of E460 strength grade.

Embodiment 3

[0032] The thickness of the steel plate in this embodiment is 50mm, and its chemical composition is C 0.12%, Si 0.24%, Mn 1.56%, Ni 0.14%, Cr 0.23%, Mo 0.09%, Nb 0.025%, Ti 0.012%, V≤ 0.02%, P≤0.015%, S≤0.002%, B 0.0027% and the balance Fe.

[0033] Manufacture steel slabs according to the above composition, heat the steel slabs to 1050-1150°C, control rolling to a specified thickness, air-cool to room temperature after rolling, and then conduct heat treatment. Samples are taken from finished marine steel plates, and then tensile and low-temperature impact tests are performed.

[0034] The heat treatment process of the test steel is as follows:

[0035] (1) Sub-temperature quenching: Heat the test steel to 790°C, keep it warm for 60min, and then water-cool to room temperature.

[0036] (2) Tempering: Heat the sample that has been quenched and cooled to room temperature to 560°C, keep it warm for 90 minutes, and then take it out and air-cool it.

[0037] After the above trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com