Hydrogen evolution reaction catalyst, and preparation method and applications thereof

An oxygen evolution reaction and catalyst technology, which is applied in the field of electrochemical catalysis, can solve the problems of high cost and achieve the effects of low cost, reduced production cost, and high oxygen evolution catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

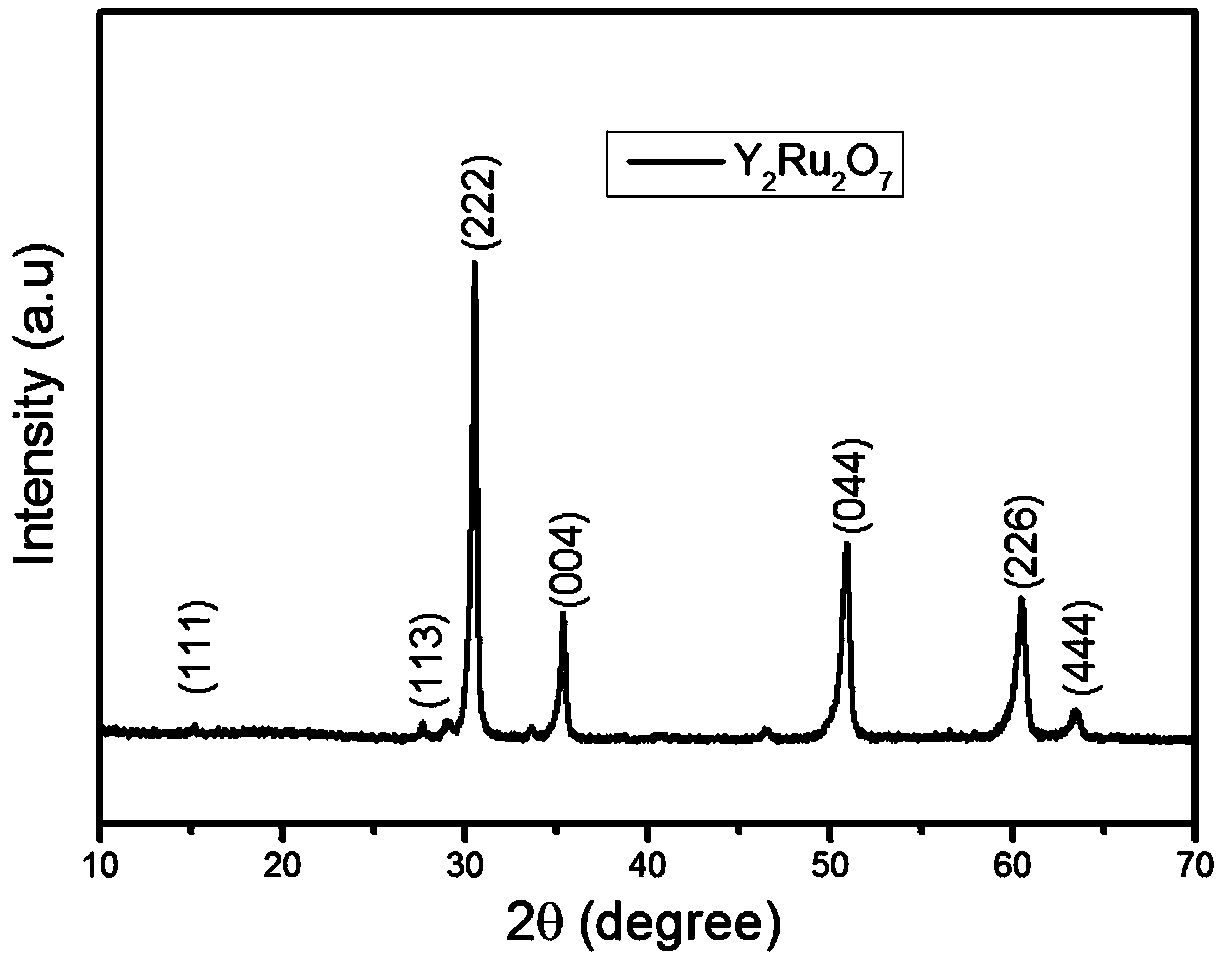

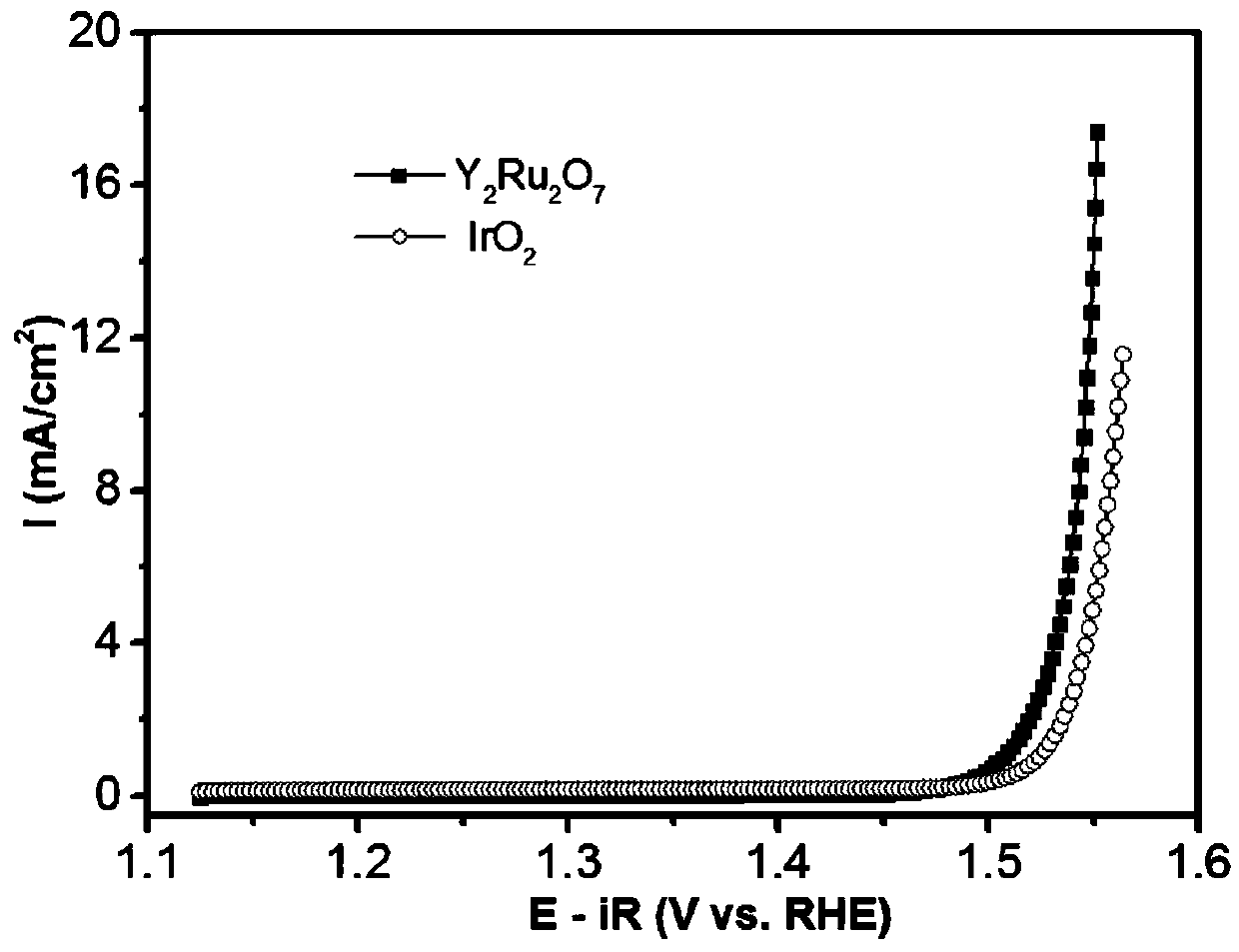

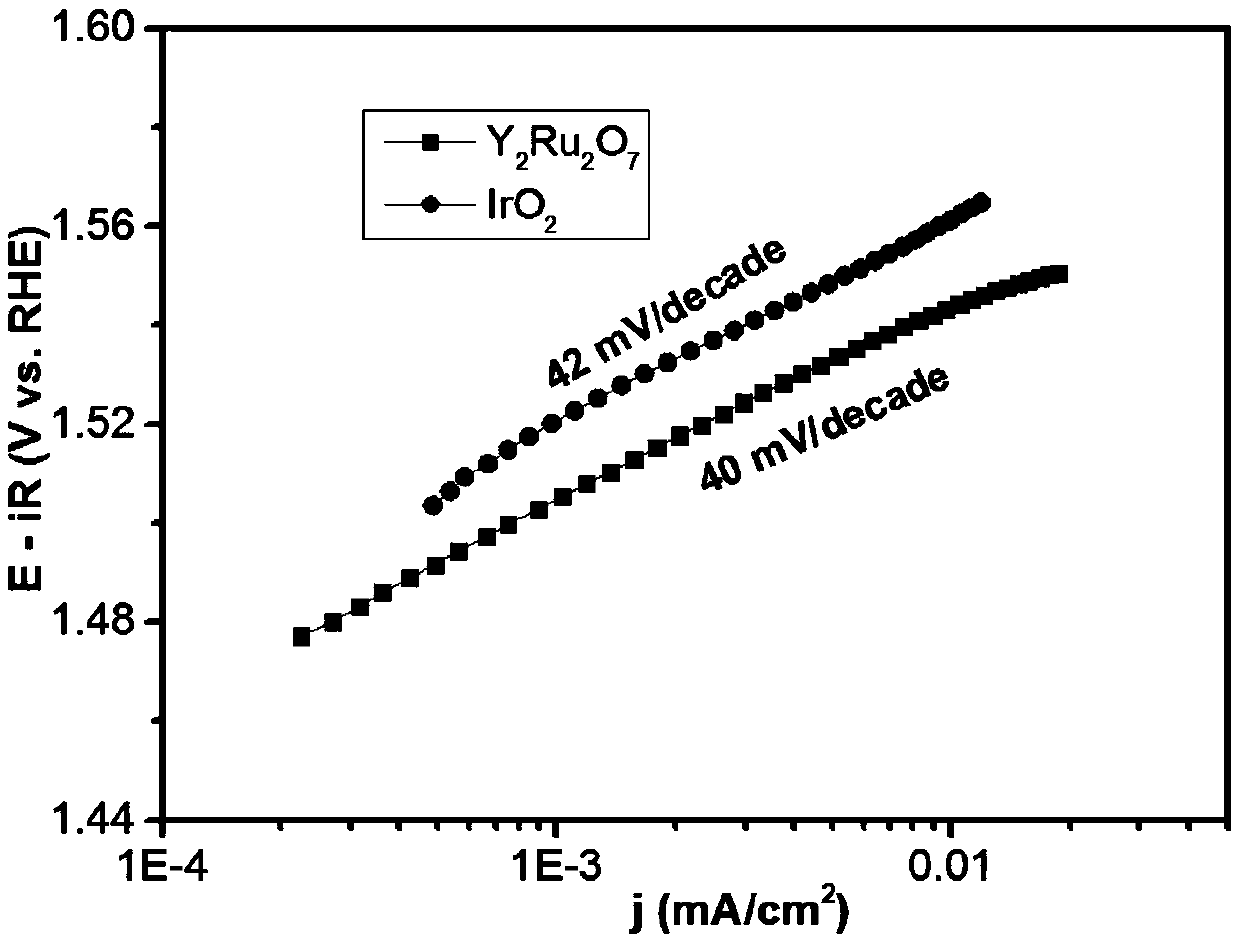

[0060] This embodiment provides an acidic oxygen evolution reaction catalyst and a preparation method thereof. The acidic oxygen evolution reaction catalyst is pyrochlore-structured Y 2 Ru 2 o 7 .

[0061] The preparation method of the acidic oxygen evolution reaction catalyst comprises the steps:

[0062] S11. Set Y(NO 3 ) 3 ·6H 2 O was dissolved in deionized water to obtain the first solution with a concentration of 0.005 mol L -1 ;

[0063] S12. RuCl 3 Add the solution described in S11 to obtain a second solution, RuCl 3 The concentration is 0.005mol L -1 , stirring for 10 minutes;

[0064] S13. Dissolve citric acid in the second solution of step S12, stir for 30 minutes, the concentration of citric acid is 0.022mol L -1 ; Adjust the pH of the mixed solution to 8.5 with ammonia water;

[0065] S14. Heat the solvent of S13 in a water bath at 80°C, evaporate the solvent to dryness, put the obtained product in a vacuum drying oven, and dry at 120°C for 10 hours; ...

Embodiment 12

[0068] This embodiment provides an acidic oxygen evolution reaction catalyst and a preparation method thereof. The acidic oxygen evolution reaction catalyst is pyrochlore-structured Y 2 Ru 2 o 7 .

[0069] The preparation method of the acidic oxygen evolution reaction catalyst comprises the steps:

[0070] S11. Set Y(NO 3 ) 3 ·6H 2O was dissolved in deionized water to obtain the first solution with a concentration of 0.01 mol L -1 ;

[0071] S12. RuCl 3 Add the solution described in S11 to obtain a second solution, RuCl 3 The concentration is 0.01mol L -1 , stirring for 10 minutes;

[0072] S13. Dissolve citric acid in the second solution of step S12, stir for 30 minutes, the concentration of citric acid is 0.05mol L -1 ; Adjust the pH of the mixed solution to 9 with ammonia water;

[0073] S14. Heat the solvent of S13 in a water bath at 85°C, evaporate the solvent to dryness, put the obtained product in a vacuum drying oven, and dry at 120°C for 10 hours;

[007...

Embodiment 13

[0076] This embodiment provides an acidic oxygen evolution reaction catalyst and a preparation method thereof. The acidic oxygen evolution reaction catalyst is pyrochlore-structured Y 2 Ru 2 o 7 .

[0077] The preparation method of the acidic oxygen evolution reaction catalyst comprises the steps:

[0078] S11. Set Y(NO 3 ) 3 ·6H 2 O was dissolved in deionized water to obtain the first solution with a concentration of 0.02 mol L -1 ;

[0079] S12. RuCl 3 Add the solution described in S11 to obtain a second solution, RuCl 3 The concentration is 0.02mol L -1 , stirring for 10 minutes;

[0080] S13. Dissolve citric acid in the second solution of step S12, stir for 30 minutes, the concentration of citric acid is 0.1mol L -1 ; Adjust the pH of the mixed solution to 9 with ammonia water;

[0081] S14. Heat the solvent of S13 in a water bath at 85°C, evaporate the solvent to dryness, put the obtained product in a vacuum drying oven, and dry at 120°C for 10 hours;

[008...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com