Device and method for steam turbine AST solenoid valve fault real-time monitoring alarm

A real-time monitoring and alarm device technology, applied in the field of energy and power, to ensure normal operation, improve system stability, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

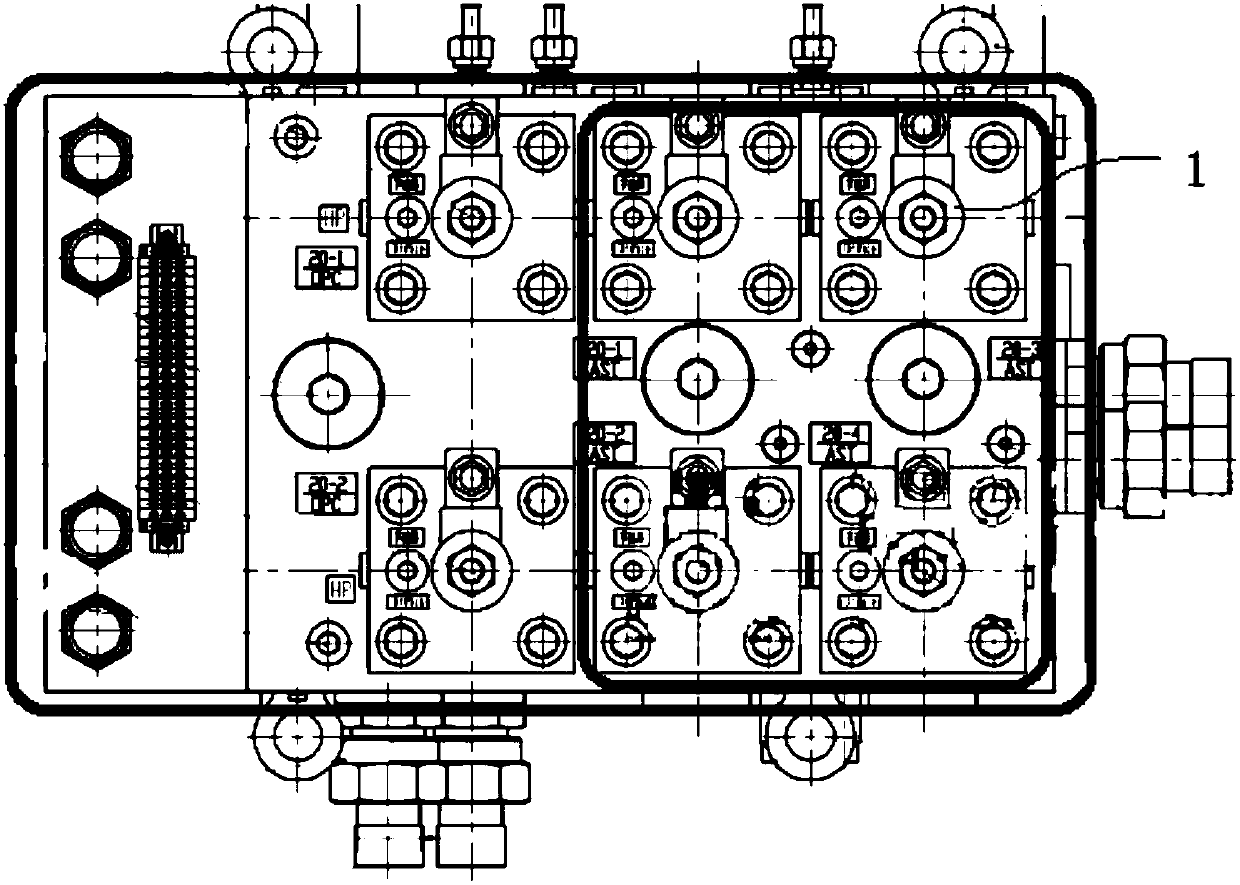

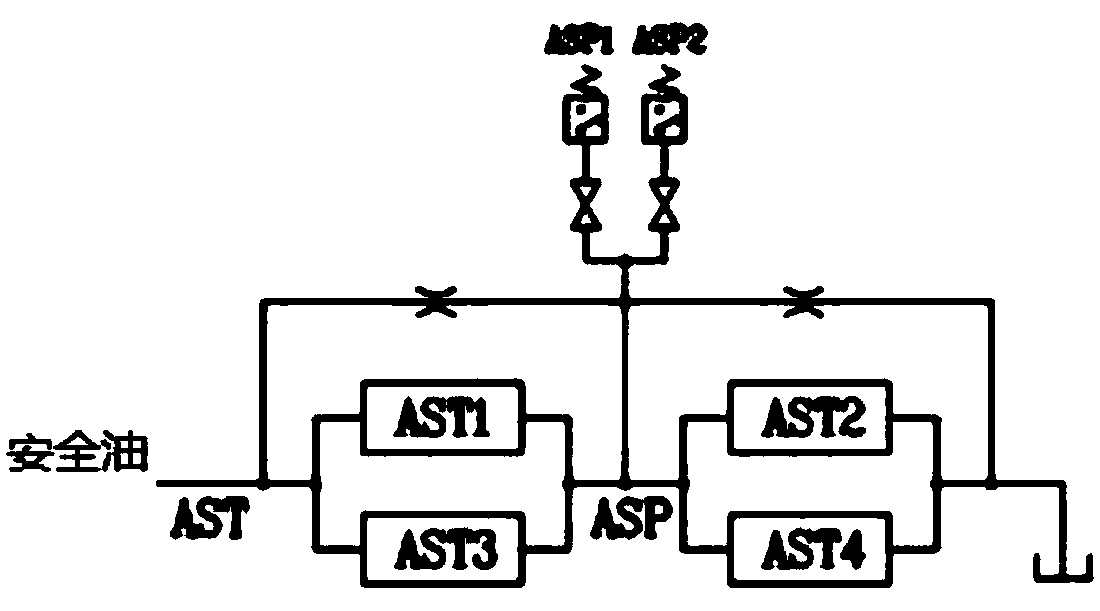

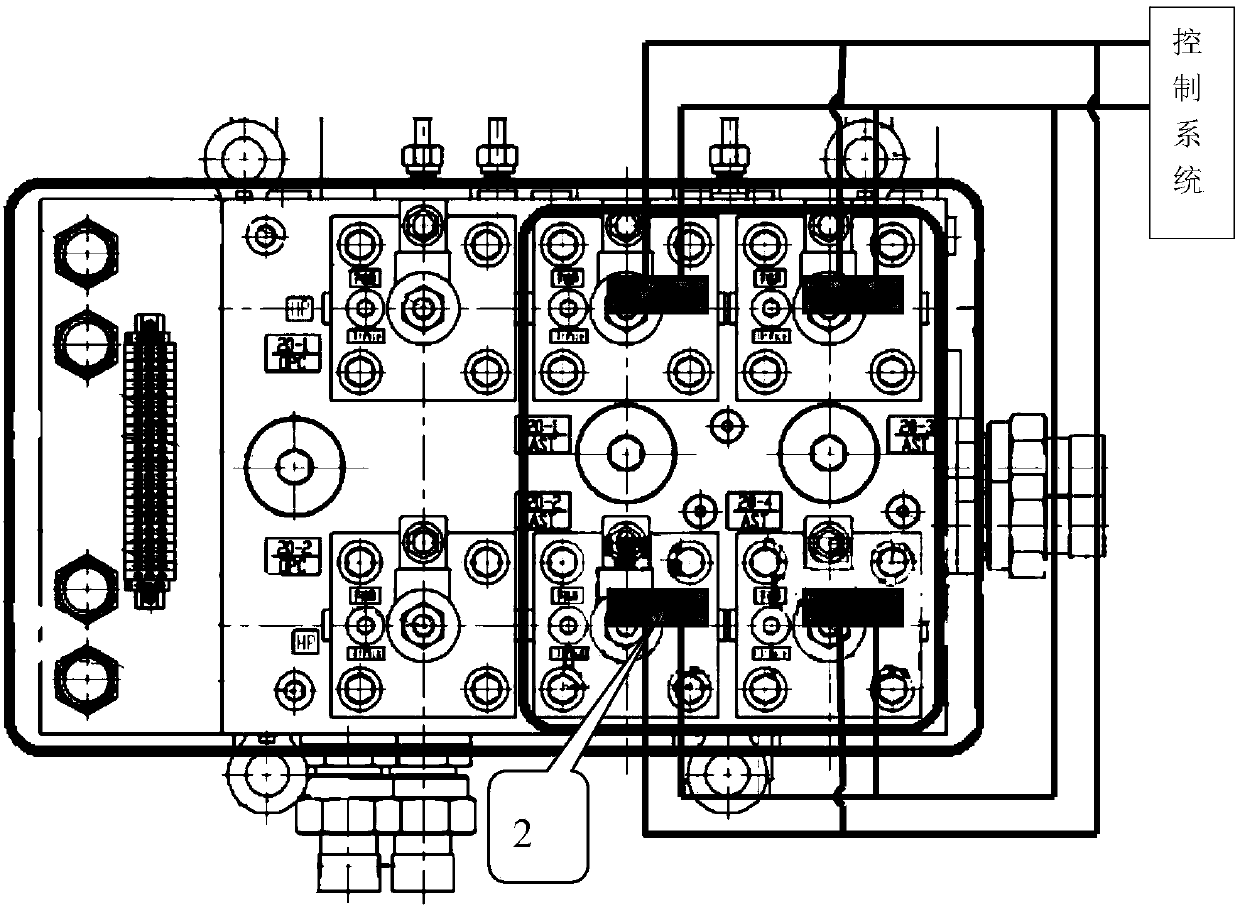

[0032] combined with Figure 1-4 , a steam turbine AST solenoid valve fault real-time monitoring and alarm device of the present embodiment includes a fault monitoring circuit, the fault monitoring circuit is located at the top of the AST solenoid valve 1, and the fault monitoring circuit is connected to the control system.

[0033] After the fault monitoring circuit detects that the AST solenoid valve 1 is faulty and power-off and closed, the feedback signal is sent to the control system, and the control system sends out an alarm. It was found that the AST solenoid valve 1 was faulty to make the steam turbine run normally. In the prior art, complex circuits are usually installed at both ends of the AST solenoid valve 1 to detect changes in its voltage or current to detect whether the AST solenoid valve 1 is faulty and power-off. Factors such as vibration and circuit failure during operation will inevitably affect the normal operation of the circuit, and the low reliability w...

Embodiment 2

[0035] A kind of steam turbine AST solenoid valve failure real-time monitoring alarm device of this embodiment is further improved on the basis of embodiment 1, such as Figure 1-4 , the AST solenoid valve 1 includes a spring, a valve body 11, a valve core 12, a spring 13 and an orifice 14, the orifice 14 is located at the bottom of the valve body 11, and the spring, the spring 13 and the valve core 12 are all located in the valve body One side of the spring 13 is provided with a spool 12 , the other side of the spring 13 is provided with a nut outside the valve body 11 , and the orifice 14 communicates with the through hole where the spring 13 and the spool 12 are located. The AST solenoid valve 1 is turned off after being energized to maintain normal oil pressure and ensure the normal operation of the steam turbine.

Embodiment 3

[0037] A kind of steam turbine AST solenoid valve failure real-time monitoring alarm device of this embodiment is further improved on the basis of embodiment 1 or 2, such as Figure 1-4 , the control system is provided with a magnetic detection and alarm circuit, and the fault monitoring circuit is connected to the magnetic detection and alarm circuit.

[0038] When the AST solenoid valve 1 fails, the fault monitoring circuit sends a signal to the magnetic detection and alarm circuit of the control system, and an alarm is issued through the magnetic detection and alarm circuit, and the staff in the central control room where the control system is located immediately go to the scene to repair the AST solenoid valve 1 Or replace it, so that the failure of AST solenoid valve 1 can be found in time to prevent the steam turbine from stopping abnormally.

[0039]The magnetic detection and alarm circuit is located in the central control room, which can be in the form of software, for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com