A low-frequency vibration isolation system and vibration reduction method

A vibration isolation system and low-frequency vibration technology, applied in control/regulation systems, mechanical oscillation control, instruments, etc., can solve the problems of weakening the low-frequency vibration isolation effect, increasing the static deformation of the system, and large bearing capacity, and achieving high-performance low-frequency Vibration isolation effect, low vibration isolation starting frequency, and small control times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation, with the purpose of helping those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and to facilitate implementation.

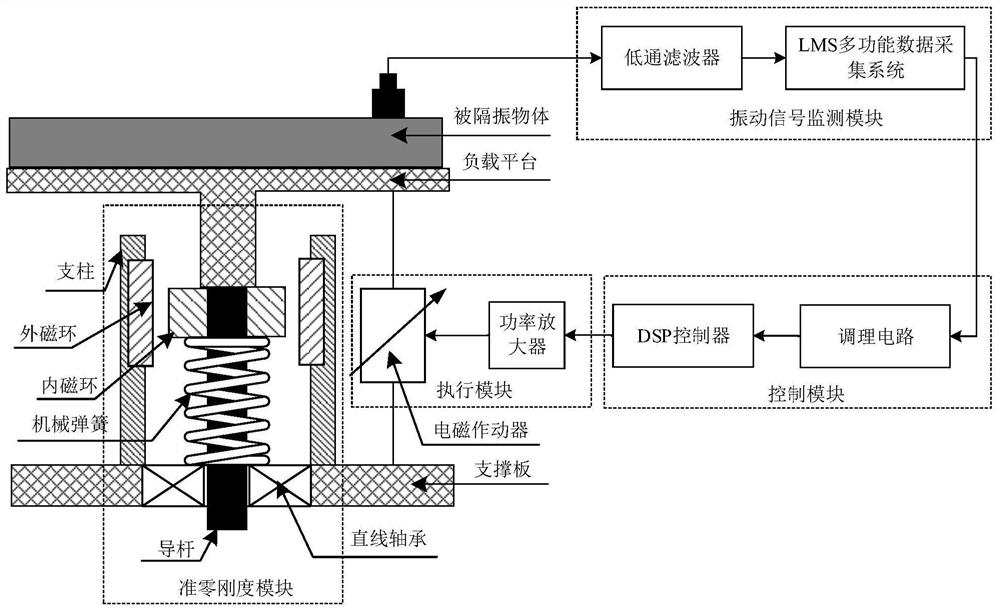

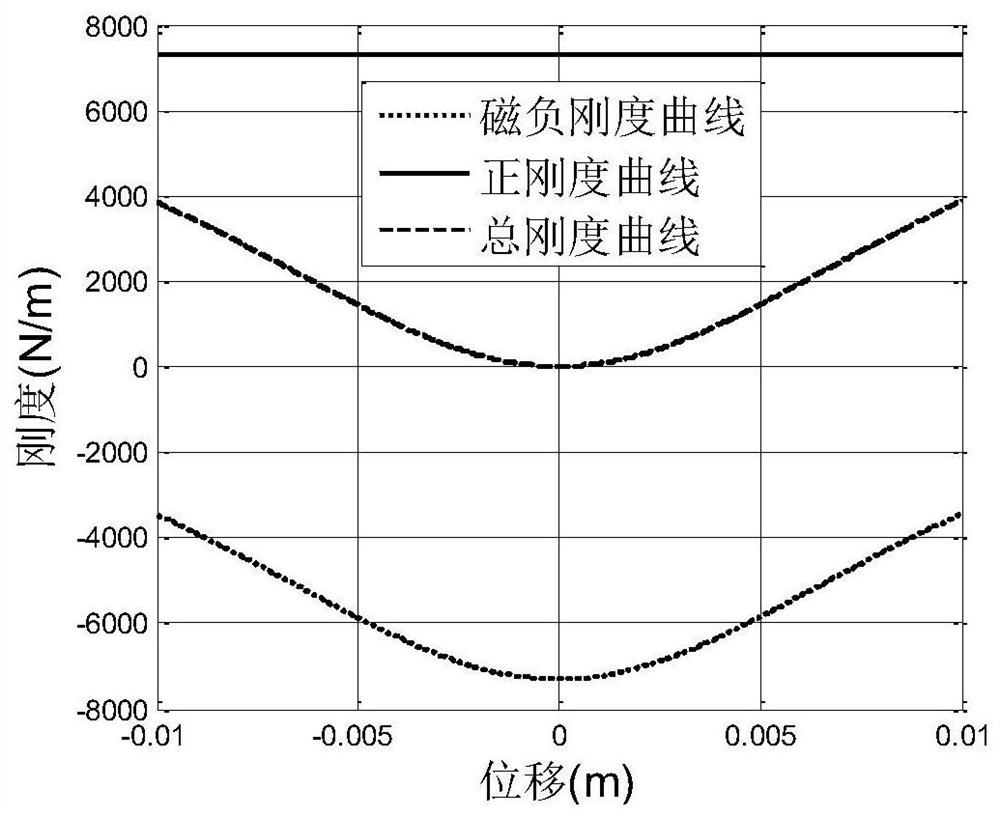

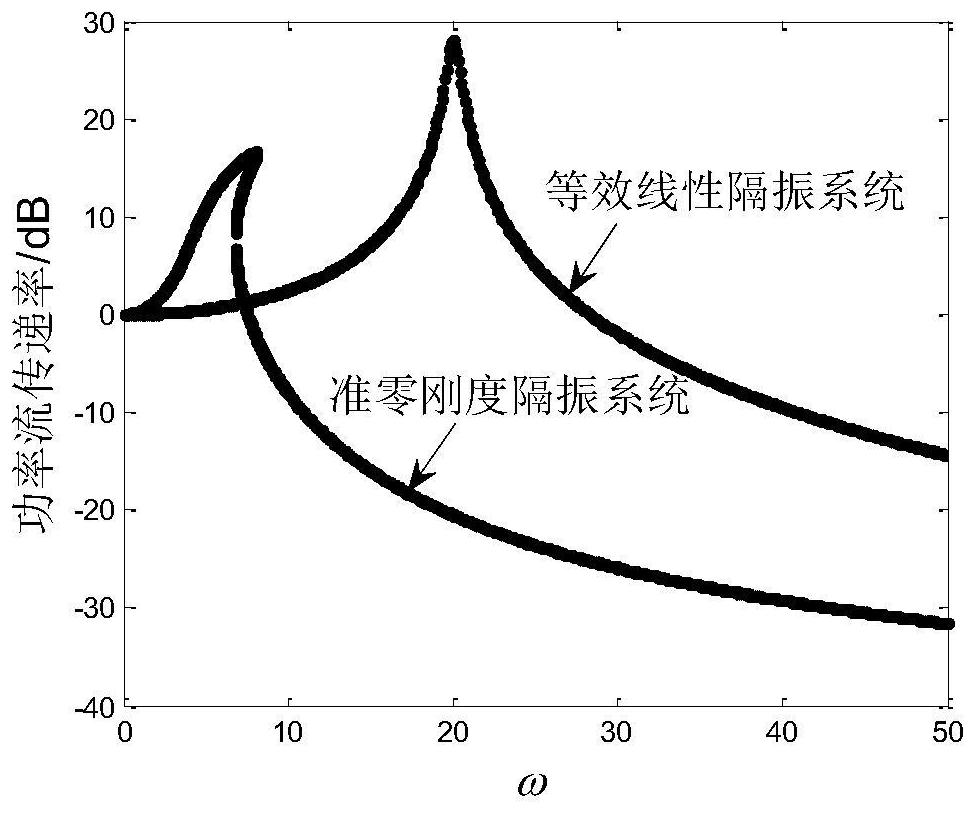

[0034] Such as figure 1As shown, a low-frequency vibration isolation system of the present invention includes a quasi-zero stiffness module, a vibration signal monitoring module, a control module and an execution module, wherein the quasi-zero stiffness module is connected with the vibration signal monitoring module, the control module and the execution module in turn; The quasi-zero stiffness module includes a T-shaped load platform, a magnetic negative stiffness mechanism, a positive stiffness mechanical spring, and a support plate from top to bottom. Among them, the magnetic negative stiffness mechanism uses a double-rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com