A method for constructing artificial pillars in underground engineering

An underground engineering and artificial technology, applied in underground mining, underground chambers, ground mining, etc., can solve the problems of difficulty in forming large-scale artificial pillars, low strength of pillars, and inability to realize high pillar space support. The effect of low cost, simple structure of expansion device and reliable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0038] The following will take the underground stope as an example to describe in detail the construction method of the artificial pillar itself and the bearing structure. It can be understood that the artificial pillar of the present invention can not only be used in underground stopes, so the description about underground stopes does not constitute a limitation of the present invention, and those skilled in the art can understand the relevant technical characteristics of underground stopes as other Corresponding features of underground works.

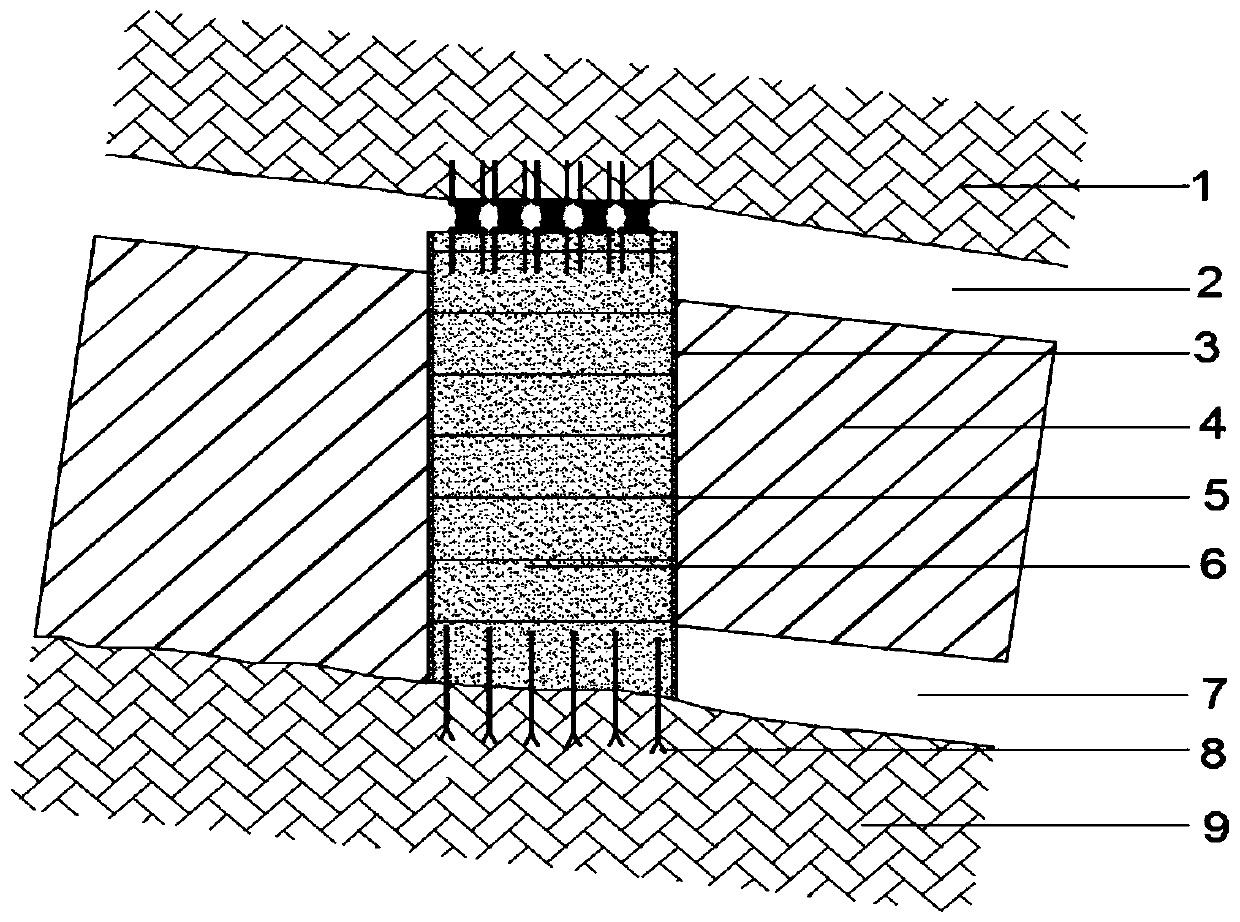

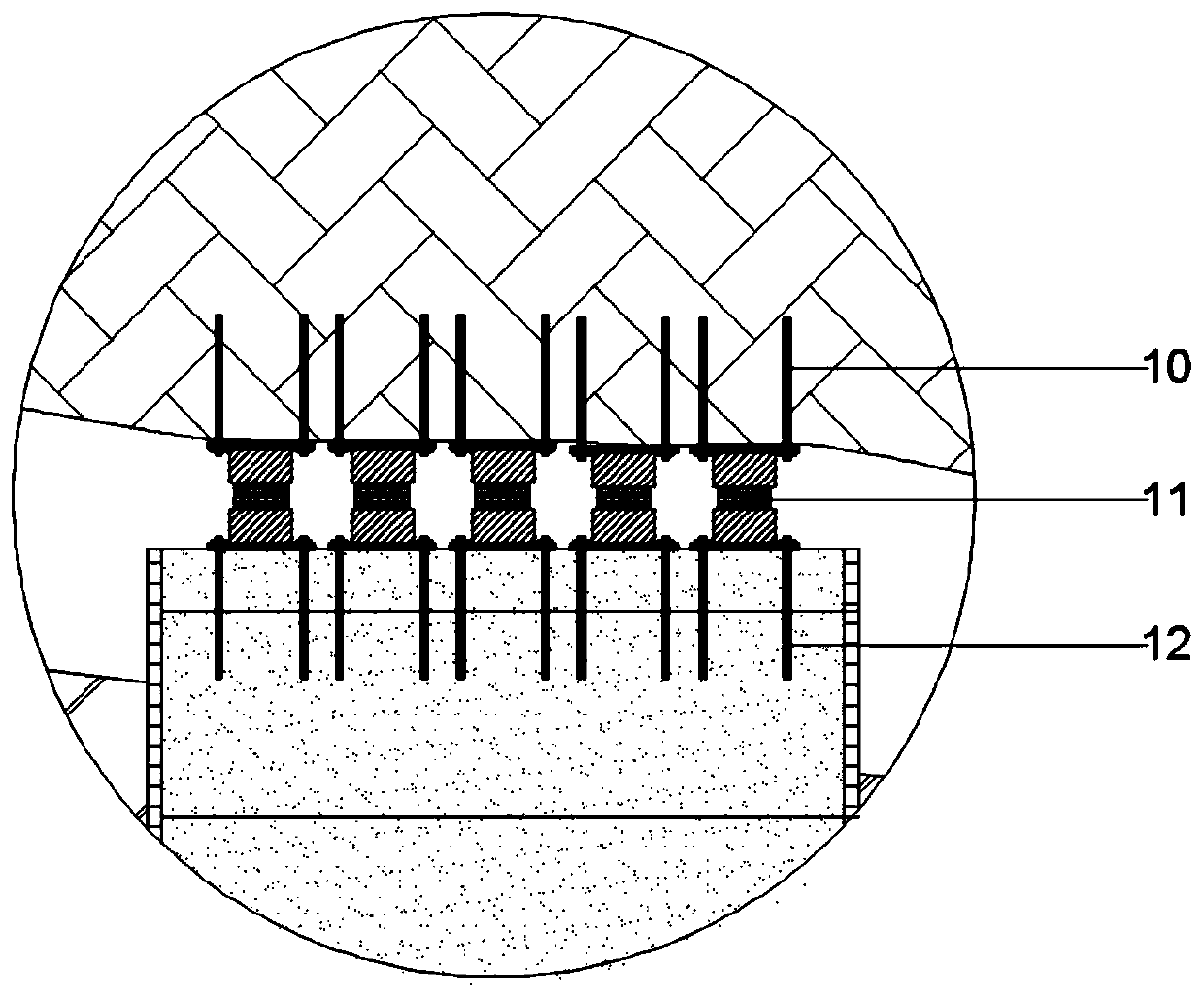

[0039] Such as figure 1 As shown, the underground engineering artificial pillar of the present invention includes an integrally cast bearing structure 6 and self-expanding roofing structures 10 , 11 , 12 . The constr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com