Top polarity testing and output value fault detection method

A fault detection and polarity test technology, applied in the detection field, can solve problems affecting the correctness of fault detection algorithm design and diagnosis, complex detection algorithms, and safe operation risks, so as to improve test safety, simplify the test process, reduce The effect of small errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

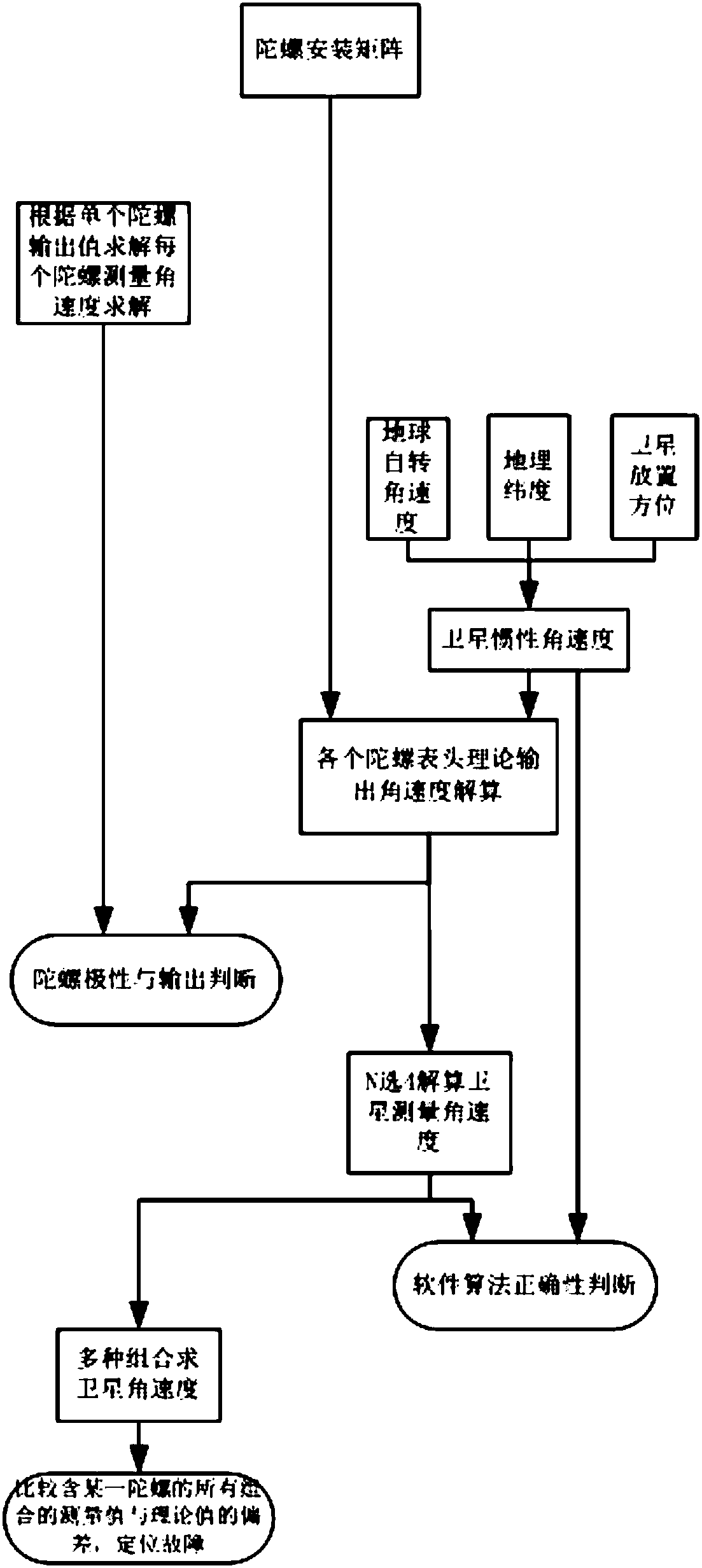

[0033] Such as figure 1 As shown, the gyroscope polarity test and the output value fault detection method of the present invention comprise the following steps:

[0034] Step 1, gyro installation matrix description;

[0035] Step 2, solving the angular velocity measured by the gyroscope;

[0036] Step 3, using the earth's rotation angular velocity to solve the theoretical value of satellite inertial angular velocity and gyro output;

[0037] Step 4, satellite inertial measurement angular velocity solution;

[0038] Step 5: Locate the faulty gyro by combining various gyro heads.

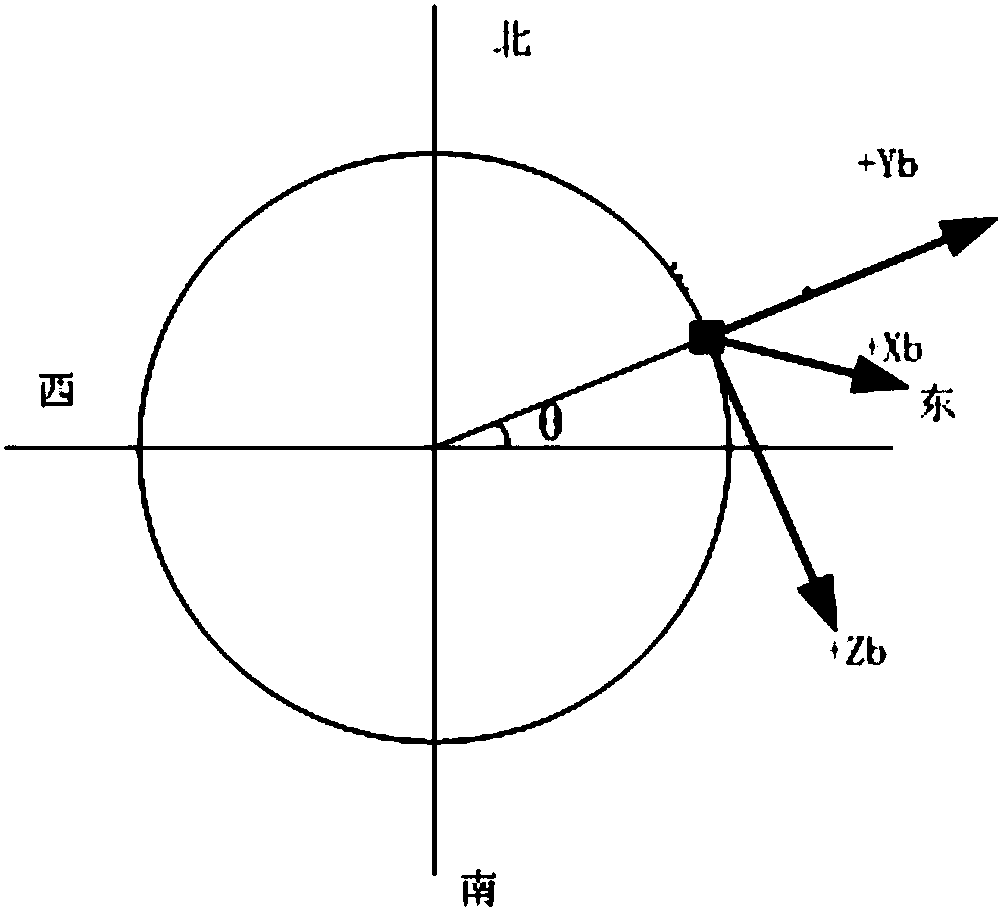

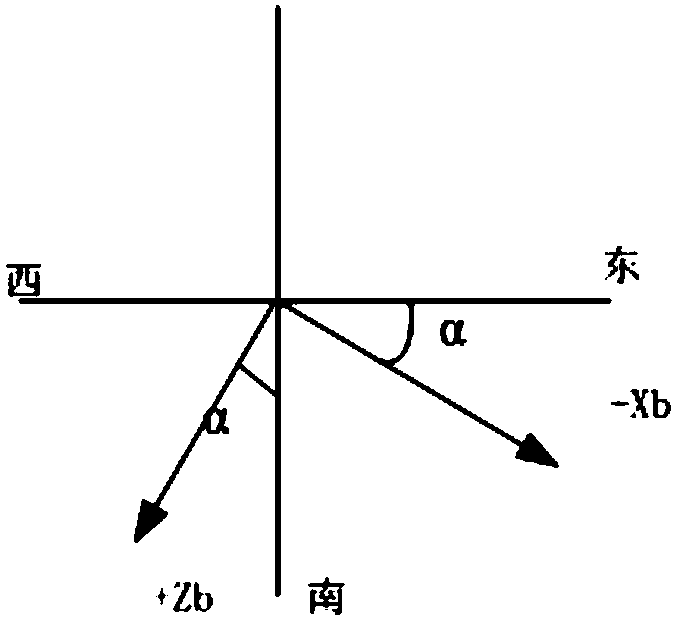

[0039] In said step 1, according to the actual installation direction of the gyroscope head, a 3×N matrix A is used to describe the gyroscope installation matrix, and N is the number of gyroscope heads on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com