Flame-retardant cable

A flame retardant cable and flame retardant layer technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of short cable life, difficult maintenance work, poor water resistance and flame retardant performance of cables, etc., and achieve good waterproof and moisture-proof effect. Good fire retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

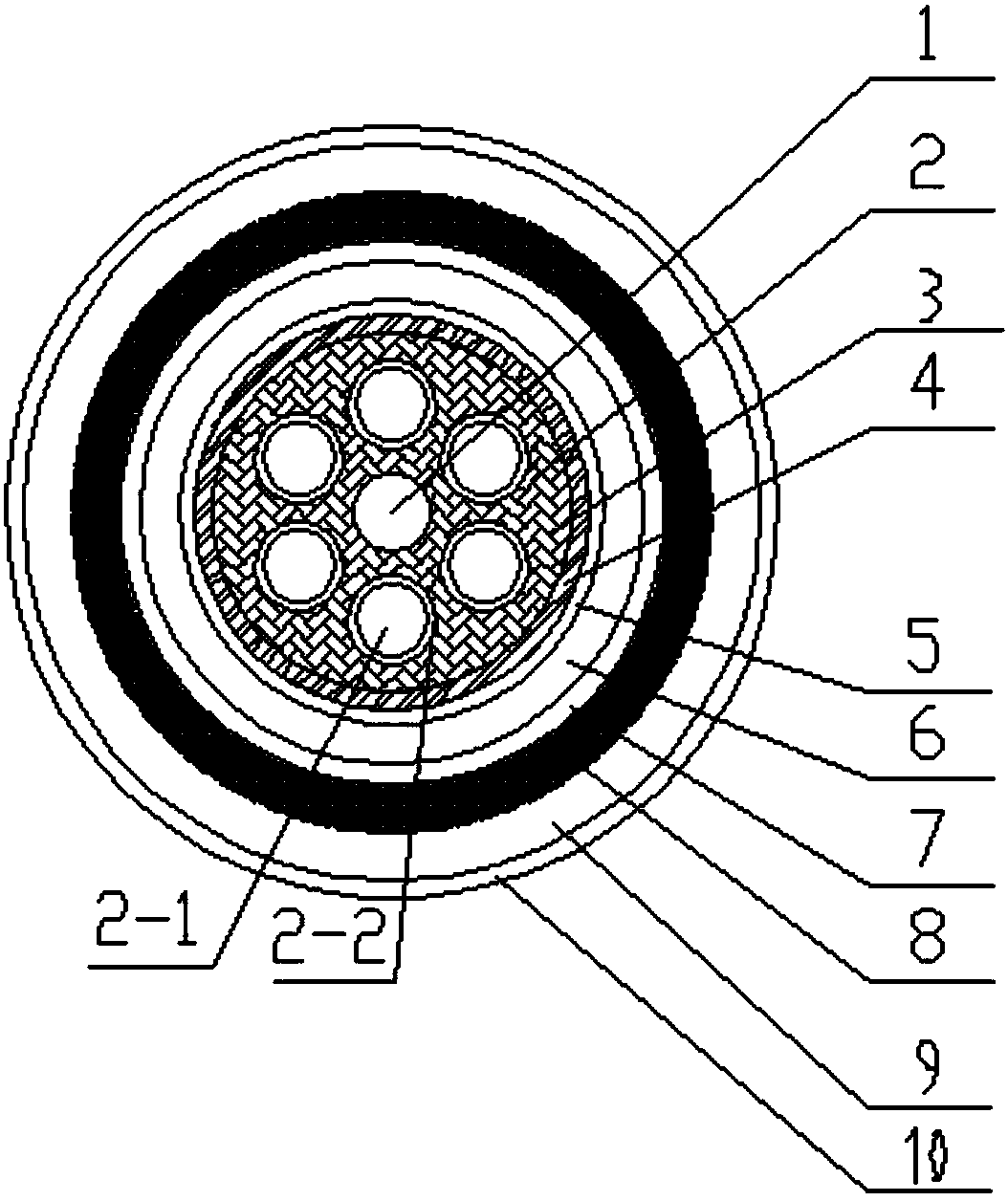

[0017] Such as figure 1 As shown, the present embodiment provides a flame-retardant cable, including a plurality of cables 2, each cable 2 includes a conductor 2-1 and a loose sleeve layer 2-2 arranged outside the conductor 2-1, and a plurality of cable cores Aramid yarn layer 4, inner sheath 5, plastic-coated steel belt layer 6, flame retardant layer 7, capsaicin layer 8, outer sheath 9 and anti-corrosion layer 10 are arranged in sequence outside the line 2, and the inner gap of aramid yarn layer 4 is It is filled with ceramic refractory silicone rubber 3, the center of multiple cables 2 is provided with a metal reinforcing core 1, and the material of the outer sheath 9 is low-smoke halogen-free polyolefin.

[0018] In this embodiment, when the young mouse bites through the outer sheath, it will bite the capsaicin layer, and the capsaicin will strongly stimulate the mouse, driving the mouse to give up biting. Even if the capsaicin layer is worn, the armor inside The layer fu...

Embodiment 2

[0020] This embodiment is further optimized on the basis of embodiment 1, specifically:

[0021] The conductor 2-1 is a copper conductor, and the conductor 2-1 is a copper wire with a diameter of 0.3mm and 0.1mm evenly arranged in a ratio of 1:2.

[0022] The plastic-coated steel strip layer 6 is formed by winding a galvanized steel strip with a thickness of 1.2-3.6mm, and small cooling holes with a diameter of 320-560um are uniformly arranged on the galvanized steel strip.

[0023] The reinforced cable core 1 is formed by re-twisting galvanized steel wires with a diameter of 0.15-0.2 mm.

[0024] The flame retardant layer 7 includes a copper wire mesh, an expanded particle layer, and a mica layer arranged sequentially from the inside to the outside, the thickness of the mica layer is 0.25-0.63mm, and the single wire diameter of the copper wire mesh is 0.21-0.98mm .

[0025] The anticorrosion layer 10 is an asphalt layer with a thickness of 0.12-0.35mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com