Corncob pith cutting and obtaining device for food chemical industry

A technology of corn cob and chemical industry, which is applied in the field of corn cob pith cutting device for food and chemical industry, which can solve the problems of low grade of raw materials, waste of resources, decline of raw material grade, etc., and achieve the effect of easy promotion, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

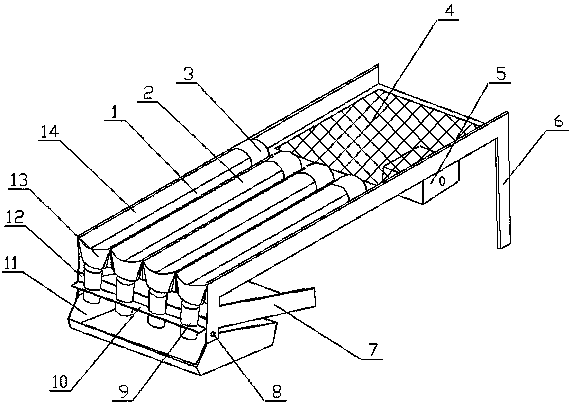

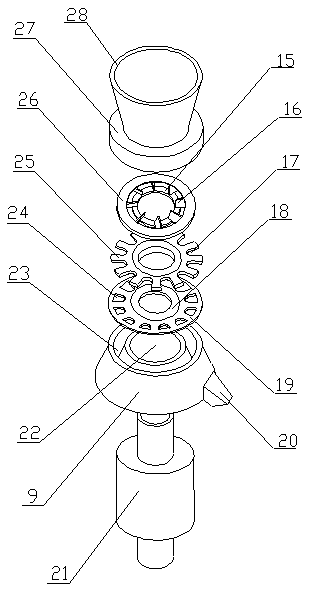

[0014] A corn cob pith cutting device for food chemical industry of the present invention is realized in the following way: when in use, the corn cob is placed on the vibrating net (4), the vibrating motor (5) is started, and the vibration of the vibrating net (4) makes the The corncob rotates and moves. When the direction of the corncob is parallel to the direction of the partition (2), it enters the channel between the partitions (2). Under the action of the arc-shaped pressing plate (3), only one corncob can enter at a time. When the corn cob slides to the position of the guide baffle (12), the corn cob changes direction along the guide baffle (12), moves from the circular gap between the guide plate (13) and the bottom plate (1), and moves vertically move down, and then enter the feed inlet (28) above the separation sleeve (9), the hollow shaft motor (21) in the separation sleeve (9) works, driving the ring cutter (15) to rotate, the ring cutter ( 15) Cut around the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com