Preparation method of soap particles

A production method and soap rice technology, applied in the direction of chemical instruments and methods, shaped soap, synthetic soap composition, etc., can solve the problems of low production efficiency, easy deposition, and inability to machine wash, etc., to reduce equipment costs and improve production efficiency , Improve the effect of yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

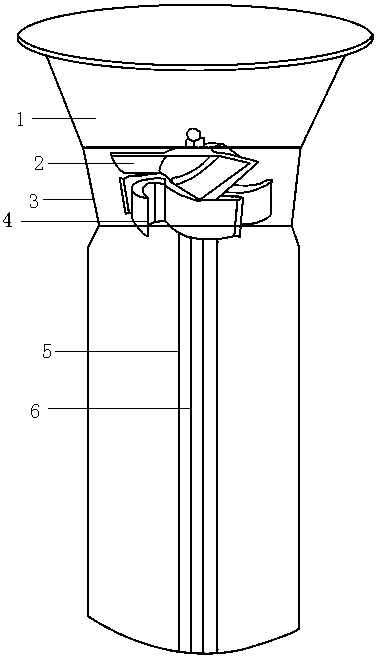

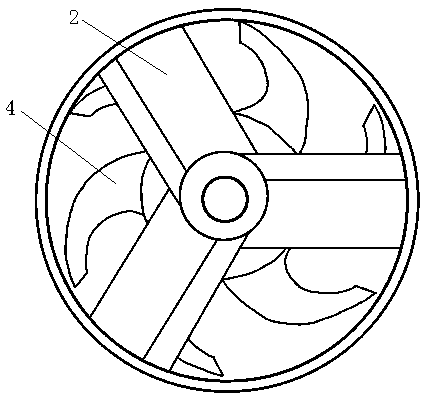

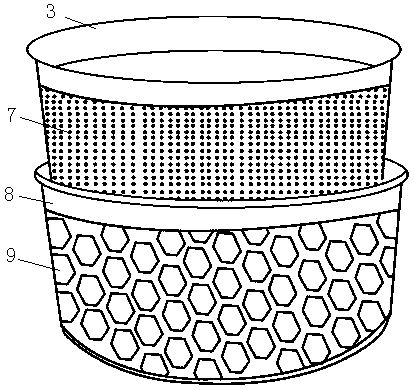

Method used

Image

Examples

Embodiment 1

[0023] The soap base raw material formula of soap rice is: 85wt% of beef or suet, 15wt% of refined coconut oil, 1.5wt% food flavor is added to the soap base, and the prepared soap rice particles are 1-5mm in length, Cylindrical with a diameter of 0.3mm. It is used for washing clothes in washing machines. It dissolves quickly, has strong detergency, low foam, easy to rinse, and has strong decontamination ability. The clothes will not harden after washing, and will not be charged with static electricity.

Embodiment 2

[0025] The soap base raw material formula components of soap rice are: 80wt% of beef or suet, 15wt% of refined coconut oil, 5wt% of palm kernel oil, and 1.2wt% food flavor is added to the soap base to make soap rice granules It is cylindrical with a length of 1-5 mm and a diameter of 0.3 mm. It is used for washing clothes in washing machines. It dissolves quickly, has strong detergency, low foam, easy to rinse, and has strong decontamination ability. The clothes will not harden after washing, and will not be charged with static electricity.

Embodiment 3

[0027] The soap base raw material formula components of soap rice are: 75wt% of beef or suet, 22wt% of refined coconut oil, 3wt% of palm kernel oil, adding 1wt% food flavor to the soap base, and the prepared soap rice particles are A cylinder with a length of 1-5 mm and a diameter of 0.3 mm. It is used for washing clothes in washing machines. It dissolves quickly, has strong detergency, low foam, easy to rinse, and has strong decontamination ability. The clothes will not harden after washing, and will not be charged with static electricity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com