Prefabricated in-fill concrete small-bore FRP tube reinforced concrete column structure and method

A reinforced concrete column and small-diameter technology, which is applied in building construction, building maintenance, construction, etc., can solve the problems of increasing the structure's self-weight, occupying a lot of building space, and long maintenance periods, achieving high bearing capacity, rigidity, and good ductility and durability, the effect of short labor time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

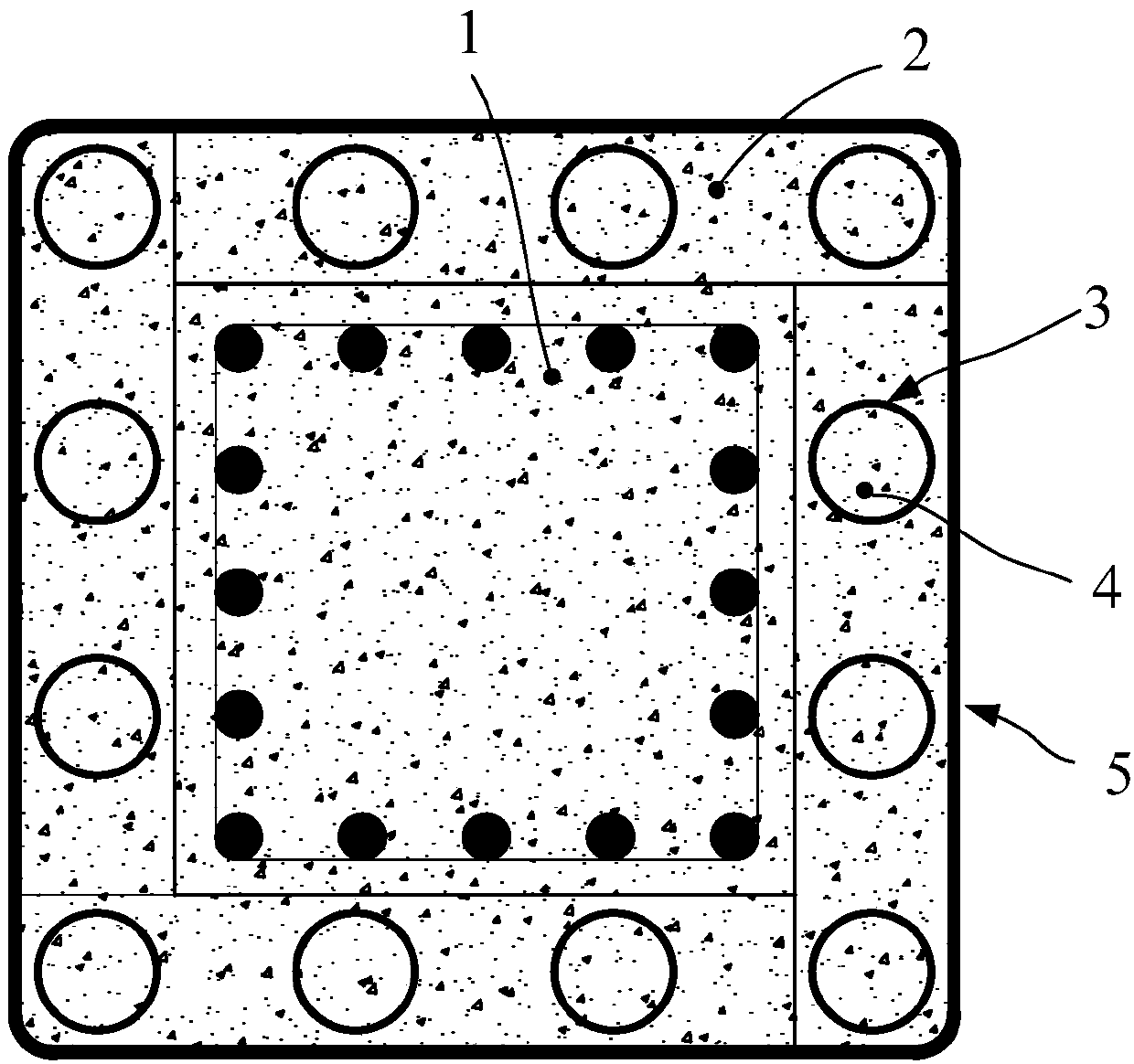

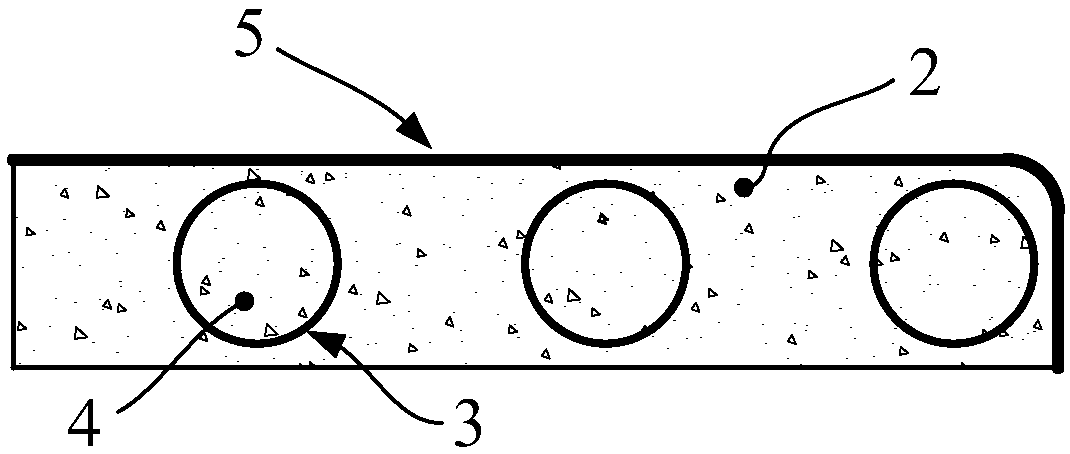

[0055] See figure 1 and figure 2 , in the embodiment of the present invention, the reinforced concrete column 1 to be reinforced is a square column, and its side length is 400 mm, the length of the prefabricated component 2 is 500 mm, and the width is 100 mm. The thickness of 5 is 0.333mm, and the original reinforced concrete column 1 is reinforced, and the specific implementation steps are as follows:

[0056] The reinforced concrete column 1 to be reinforced is inspected and repaired, and the outer surface of the original column is polished and cleaned up. The surface of the reinforced concrete column 1 can be polished with a commonly used pneumatic chisel machine. After grinding, use high-pressure water to remove the concrete impurities left by grinding. After the surface to be treated has been left to dry for at least one day, use a high-pressure air pump to blow off the surface to ensure its cleanliness.

[0057] Then paint the adhesive evenly on the treated surface as...

Embodiment 2

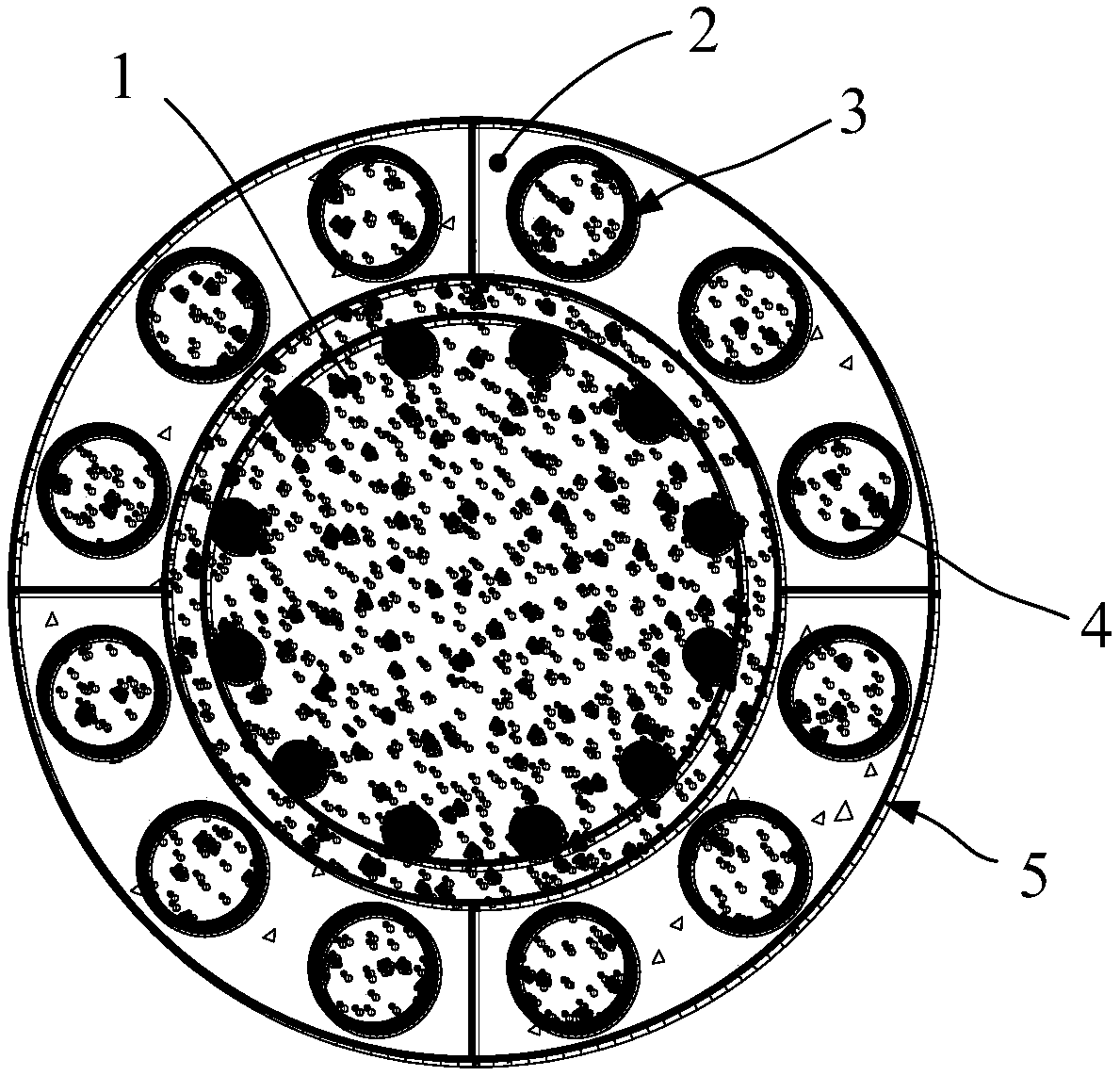

[0062] Such as image 3 and Figure 4 , in the embodiment of the present invention, the reinforced concrete column 1 to be reinforced is a cylinder with a diameter of 800mm, the inner diameter of the prefabricated component 2 is 800mm, and its outer diameter is 1000mm, and the outer diameter of the small-diameter FRP inner pipe 2 is 60mm, and the GFRP The thickness of cloth 5 is 0.333mm, and the original reinforced concrete column is reinforced, and the specific implementation steps are as follows:

[0063] The reinforced concrete column 1 to be reinforced is inspected and repaired, and the outer surface of the original column is polished and cleaned up. The surface of the reinforced concrete column 1 can be polished with a commonly used pneumatic chisel machine. After grinding, use high-pressure water to remove the concrete impurities left by grinding. After the surface to be treated has been placed and dried for at least one day, use a high-pressure air pump to blow the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap