Floating caliper disc type brake

A disc brake and floating caliper technology, applied in the direction of brake type, axial brake, brake parts, etc., can solve the problems of difficulty in adapting to the use requirements, complex structure of the brake caliper, slow braking response, etc., and achieve good practicality High performance, simple structure, and improved response efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

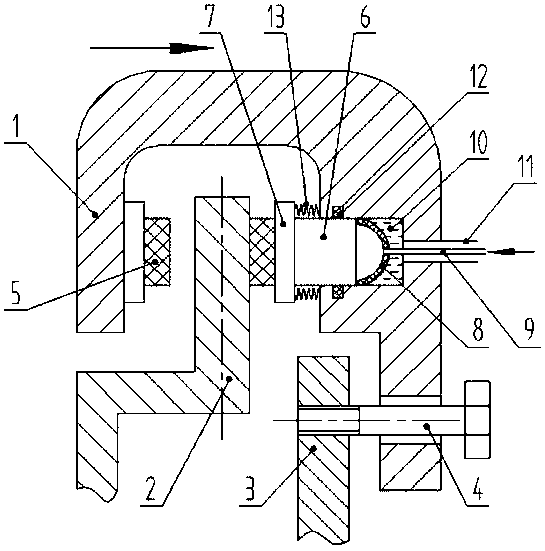

[0022] Such as figure 1 As shown, a floating caliper disc brake includes a brake caliper 1 and a brake disc 2; The brake disc 2 slides; the brake caliper 1 is erected on both sides of the brake disc 2 in a C shape; it is located on both sides of the disc body of the brake disc 2, and two sets of brake calipers are symmetrically installed on the brake caliper 1 Brake friction plates 5, wherein a group of friction plates 5 are connected to the piston 6; an oil chamber 10 is provided in the caliper of the brake caliper 1, and one end of the oil chamber 10 communicates with the outside through an oil inlet 11 The oil input mechanism is connected, and the oil inlet 11 is located at the center of the oil chamber 10; the piston 6 is located at the other end of the oil chamber 10, which is used for hydraulic power output, so that the friction plate 5 on it is at the center of the piston 6 Press against the brake disc 2 during the moving process; an inflatable airbag 8 is also provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com