An electrochemical testing method and device based on automatic coating and micro-liquid cell

A test device, electrochemical technology, applied in the direction of measuring devices, scientific instruments, instruments, etc., can solve problems such as high ohmic resistance, achieve the effect of increasing the reaction area ratio, reducing leakage, and eliminating the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

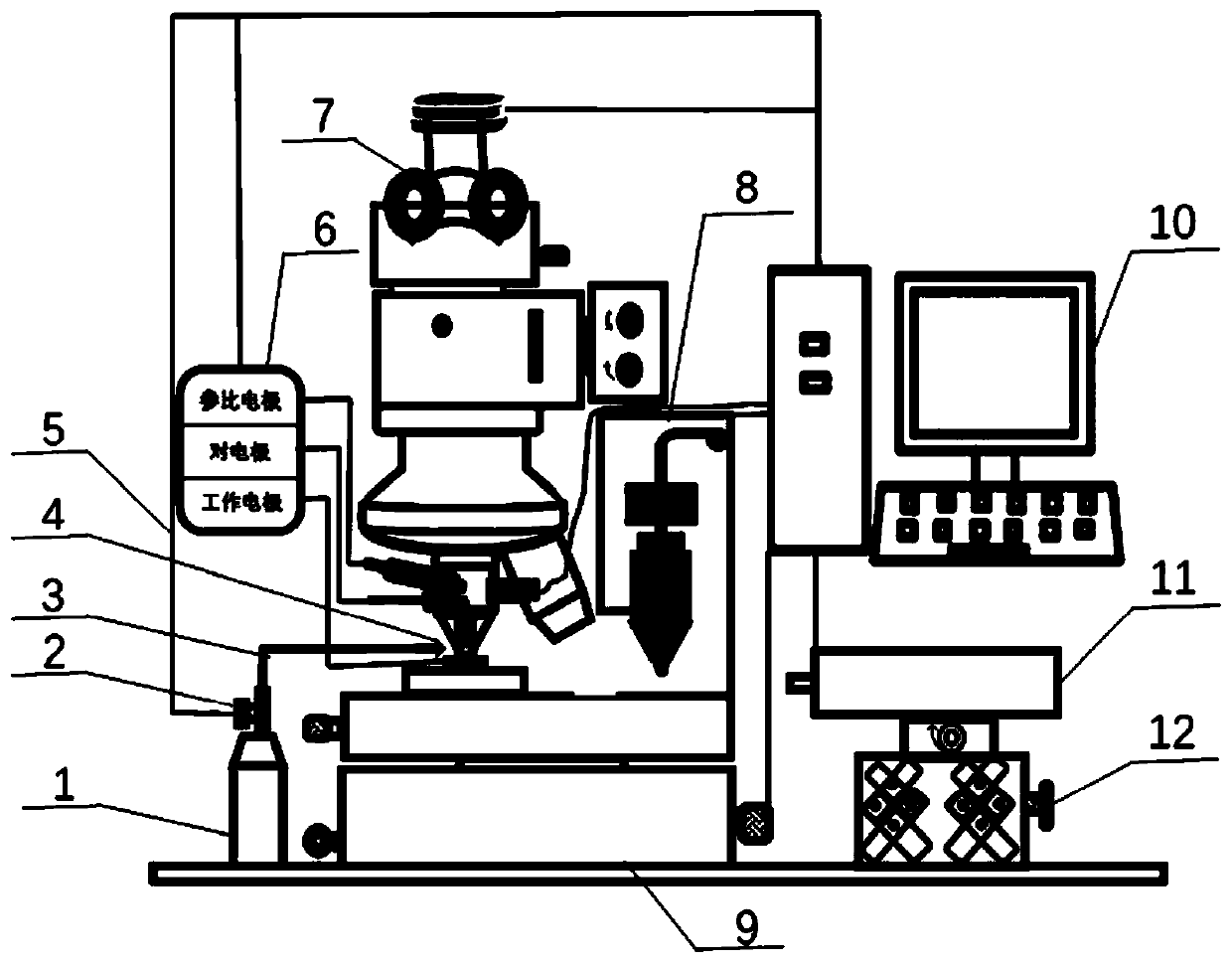

[0056] This embodiment provides an electrochemical test device based on an automatic film coating and a micro-liquid cell, wherein the electrochemical test device includes:

[0057] The automatic coating system can coat other areas on the surface of the metal sample other than the micro-area of the metal sample to be tested as needed to complete the electrochemical sealing of the metal sample micro-area;

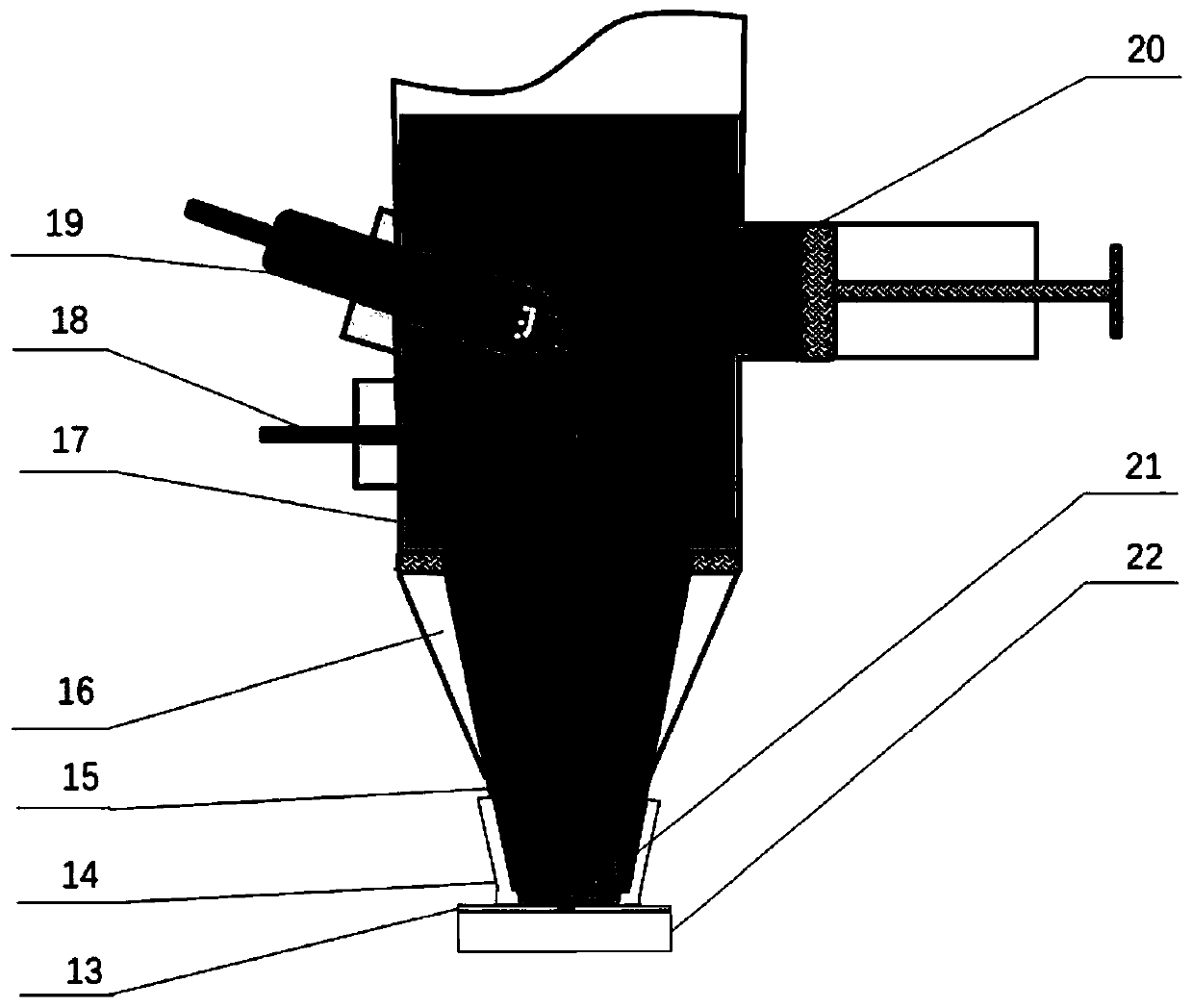

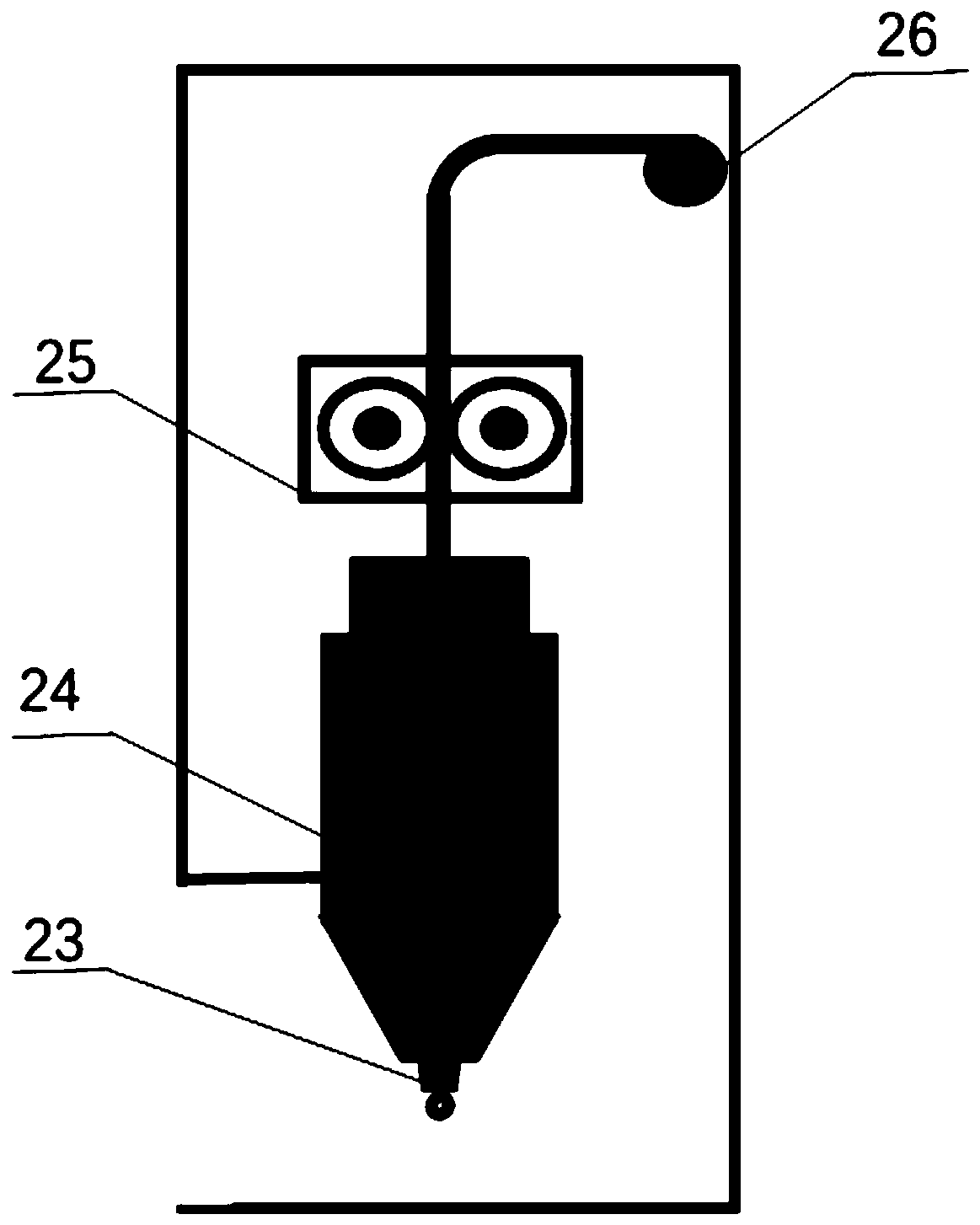

[0058] The micro-liquid cell test system is used to provide a stable micro-liquid cell required for the electrochemical measurement of the micro-area of the metal sample to be tested and to provide the counter electrode and the reference electrode in the three-electrode system, and can find and locate the metal to be tested The location of the sample micro area;

[0059] The high-precision XYZ three-dimensional mobile platform system can adjust the position and angle of the metal sample in the three-dimensional direction;

[0060] An electrochemical test system capable of perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com