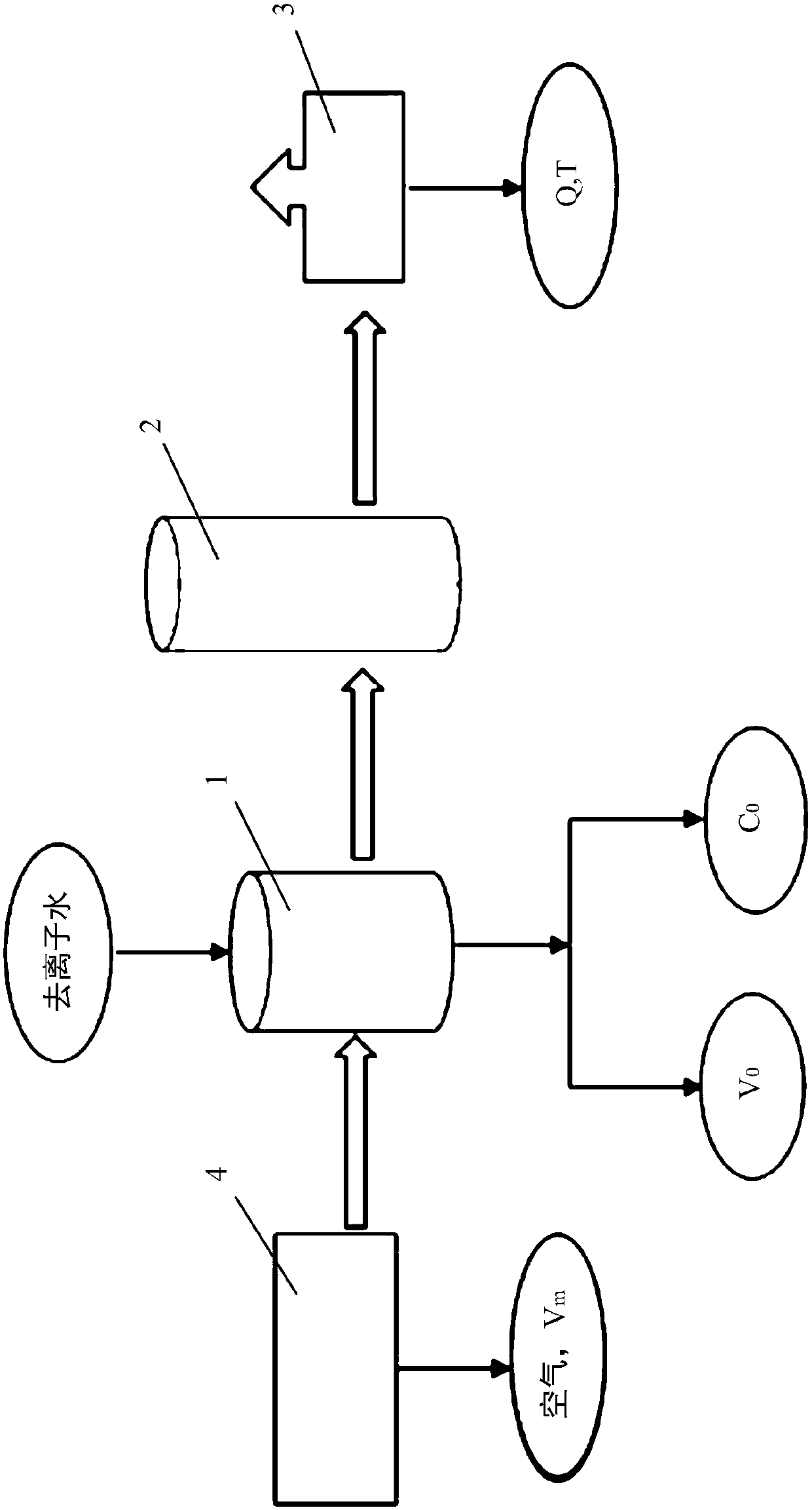

System for detecting corrosive gas concentration in air

A corrosive gas and concentration technology, applied in the measurement of color/spectral characteristics, etc., can solve the problems of poor measurement stability and reliability, large measurement error, etc., to achieve good measurement stability and reliability, small measurement error, and easy sticking The effect of laminating machine production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

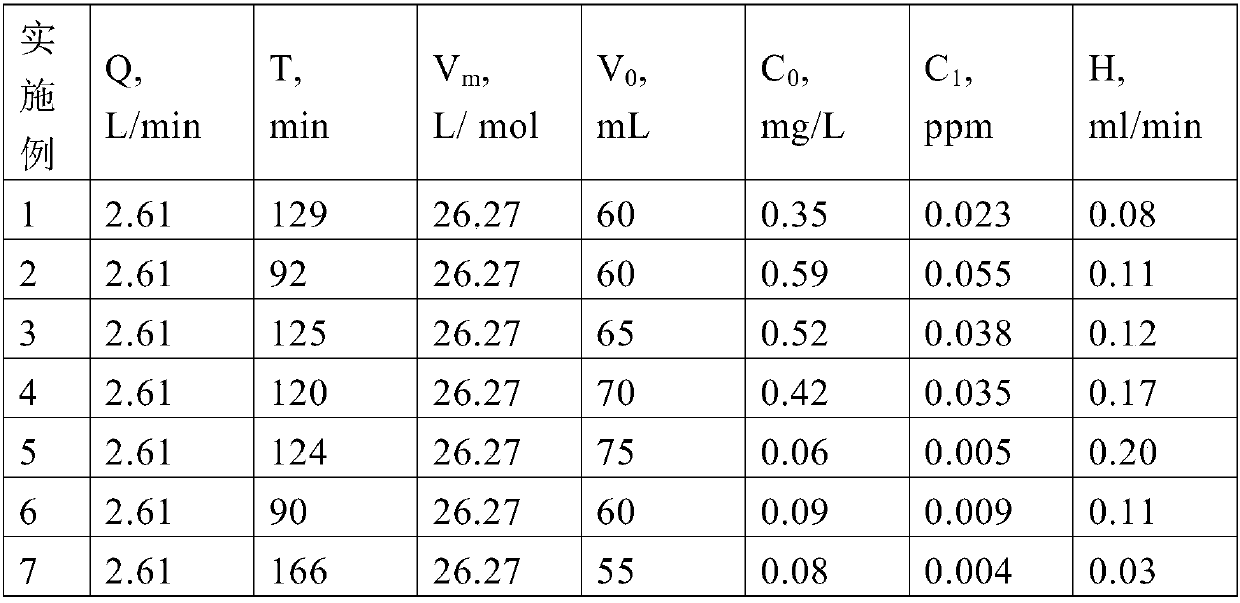

[0060] The inventor adopts the system for detecting the concentration of corrosive gases in the air of the present invention, adopts the same suction pump suction speed Q=2.61L / min, and adopts different suction times T, aiming at the shield cover of the dryer section of the paper machine. Multiple detections to measure the concentration C of corrosive substances in the absorption liquid in the absorption container after the suction is completed 0 , The volume V of the absorption liquid in the absorption container after the suction is completed 0 , and finally convert the concentration C of corrosive gas in the air where the corrosive gas is sampled 1 .

[0061] It should be noted that the air temperature and air pressure basically determine the air molar volume V m . After calculation, the air molar volume V at the shroud of the dryer section of the paper machine m Generally 26.67L / mol.

[0062] In addition, the air humidity H at the corrosive gas sampling place is also c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com