Thermal power generating unit coordinated control system energy-saving optimization technique

A technology for coordinating control systems and thermal power units, which is applied in general control systems, control/regulation systems, adaptive control, etc., can solve problems such as neglect and massive transformation costs, and achieve the effects of reducing coal consumption, improving regulation quality, and promoting optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

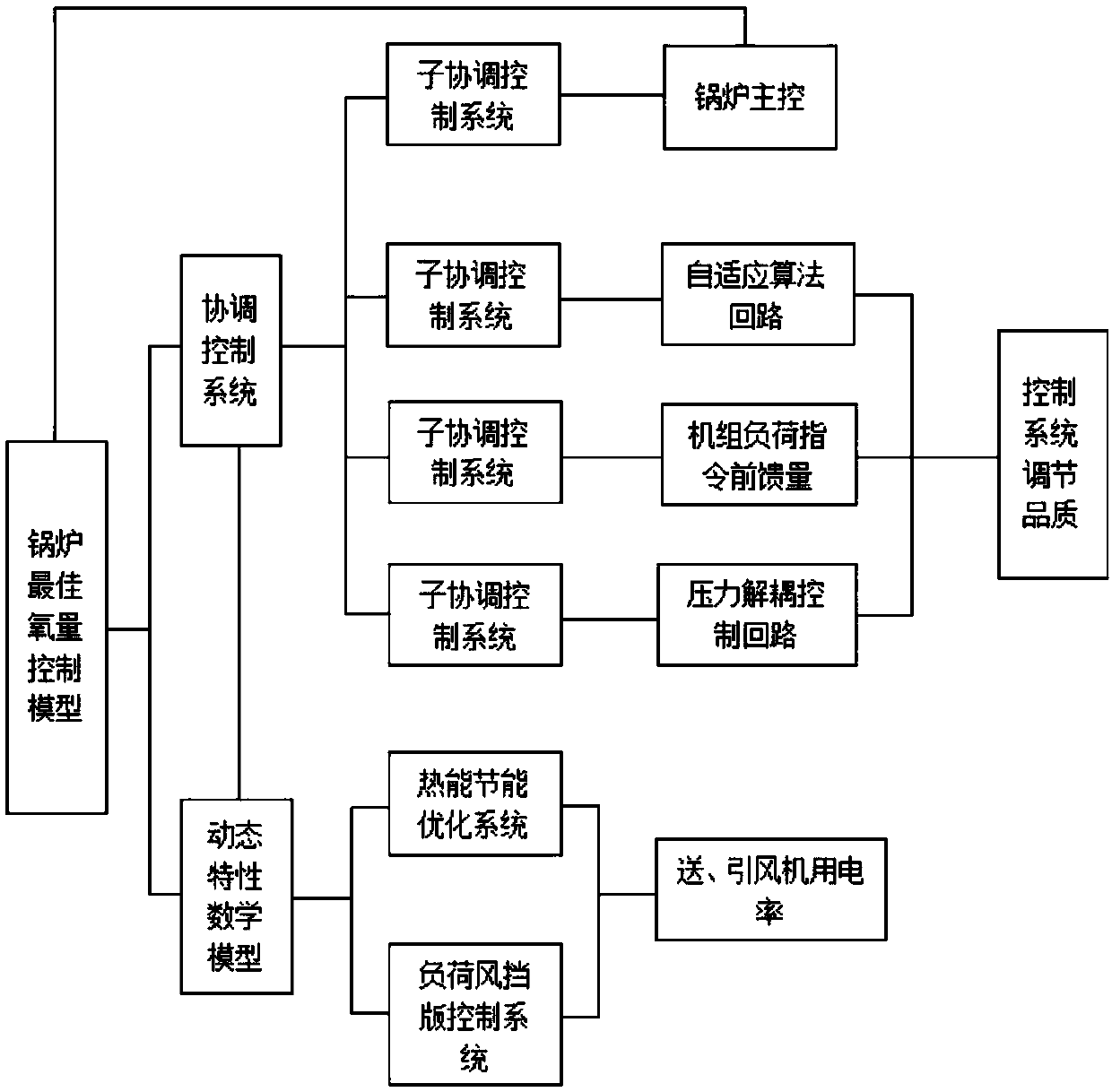

[0019] Such as figure 1 As shown, an energy-saving optimization technology for the coordinated control system of thermal power units, it re-optimizes the dynamic model of the boiler combustion control system by establishing the optimal oxygen control model of the boiler, including the optimal control of the combustion control ratio, especially the boiler Accurately optimize and control the combustion excess air coefficient, and then carry out in-depth optimization on the dynamic characteristic mathematical model of the double-inlet and double-outlet coal mill and the coordinated control system. The material level of the machine and the amount of coal entering the furnace,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com