Method for optimizing BGA welding spot return loss

A technology of return loss and solder joints, applied in the field of signal integrity of microelectronic packaging, can solve problems such as malfunction, data loss, and system performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

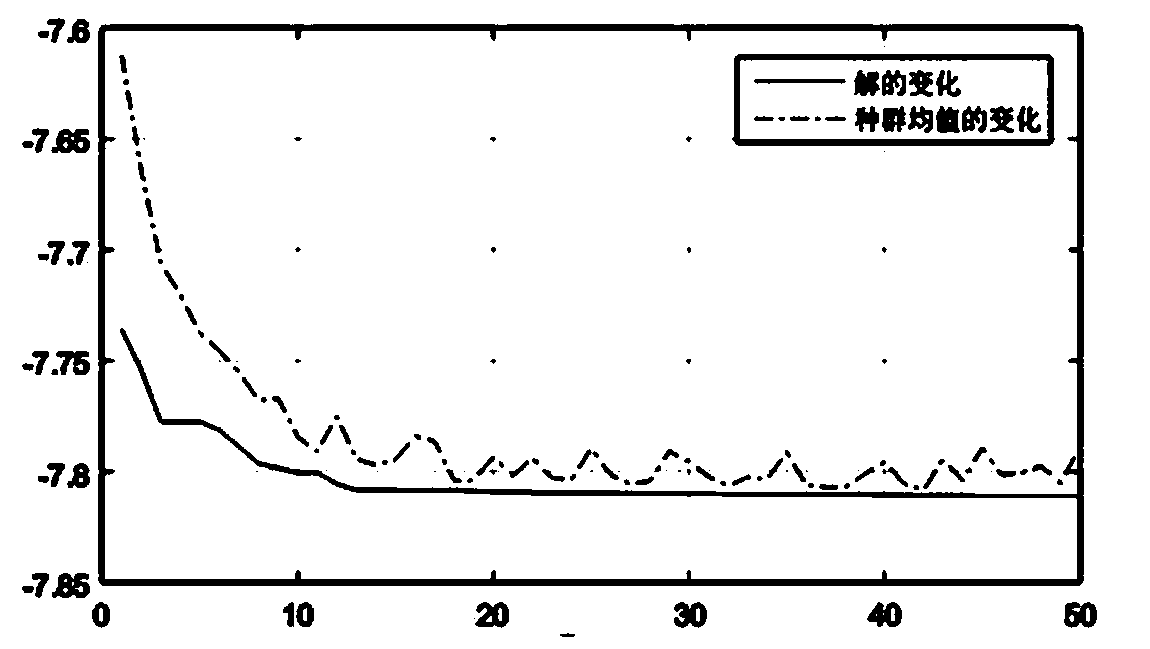

[0041] refer to Figure 6 , a method for optimizing the return loss of a BGA solder joint, comprising the steps of:

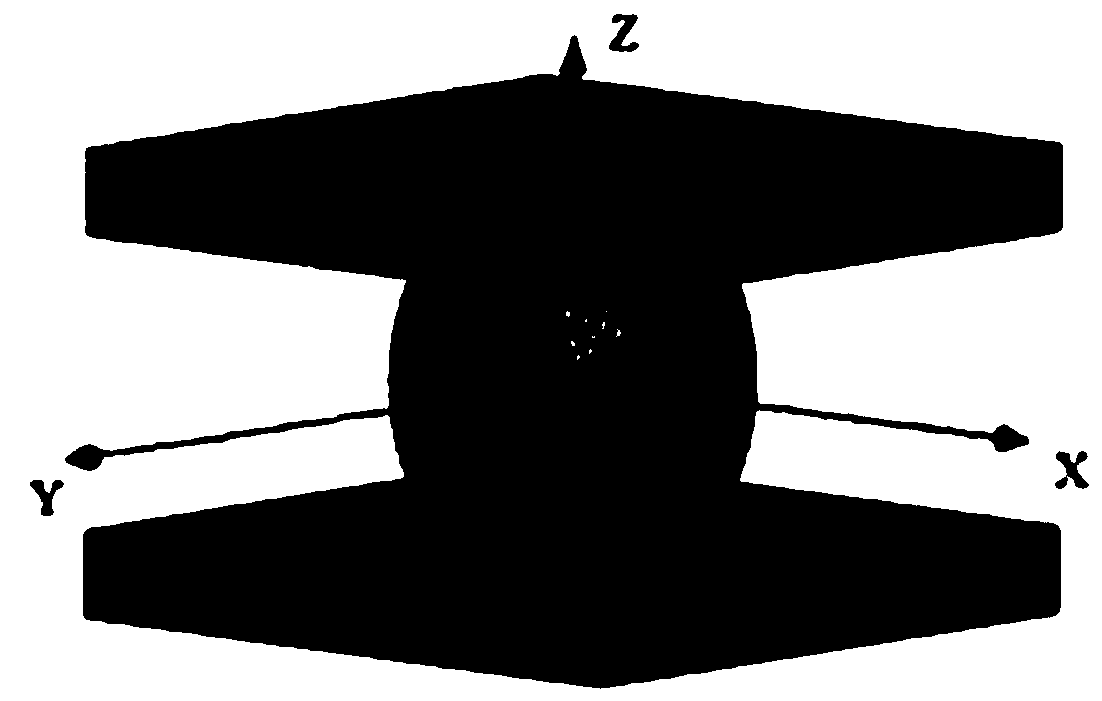

[0042] 1) Establish a BGA solder joint signal integrity analysis model: the model is a sequentially stacked printed circuit board, solder joint and organic substrate from bottom to top;

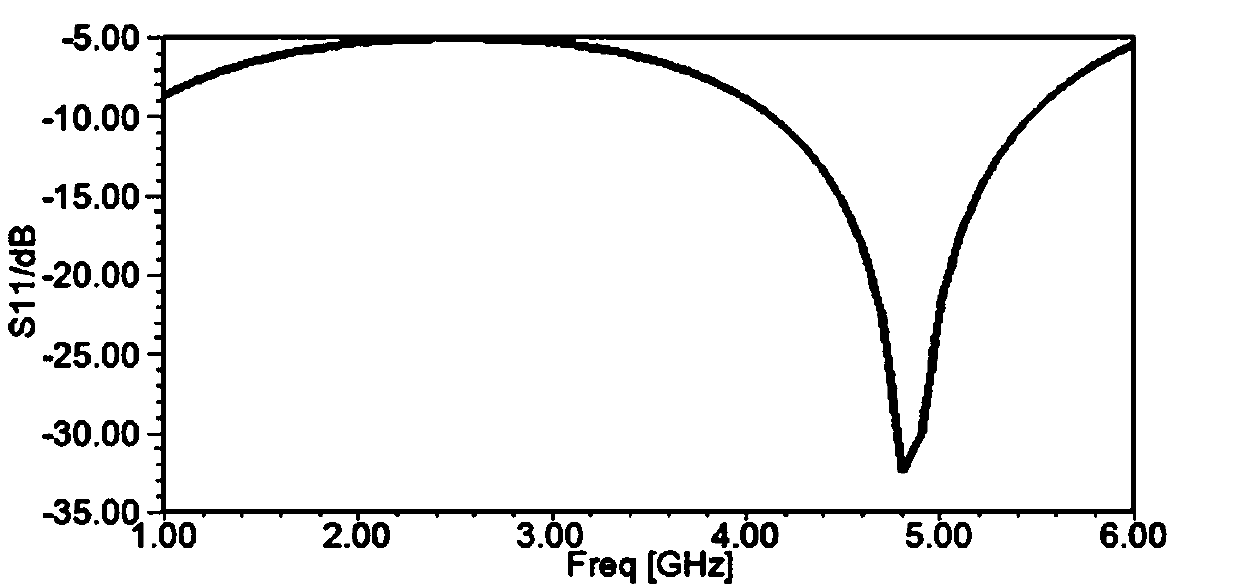

[0043] 2) Obtain the return loss of the BGA solder joint: apply wave port excitation to the model built in step 1), then use HFSS software to simulate and analyze the model to obtain the return loss of the BGA solder joint;

[0044] 3) Establish the influencing factors of the signal integrity of the BGA solder joint: the influencing factors are the maximum radial size of the solder joint, the height of the solder joint, and the diameter of the pad;

[0045] 4) Establish the parameter level value of the influencing factors of BGA solder joint signal integrity: select three sets of horizontal values of the maximum radial size of the solder joint, the height of the solder join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com