Dual-pulley rack and dual-pulley hanging system formed by same

A technology of double pulleys and pulleys, which is applied in the field of hangers, can solve problems such as job hopping, crossing, and damaged wires, and achieve the effects of ensuring the quality of display, improving passability, and low engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

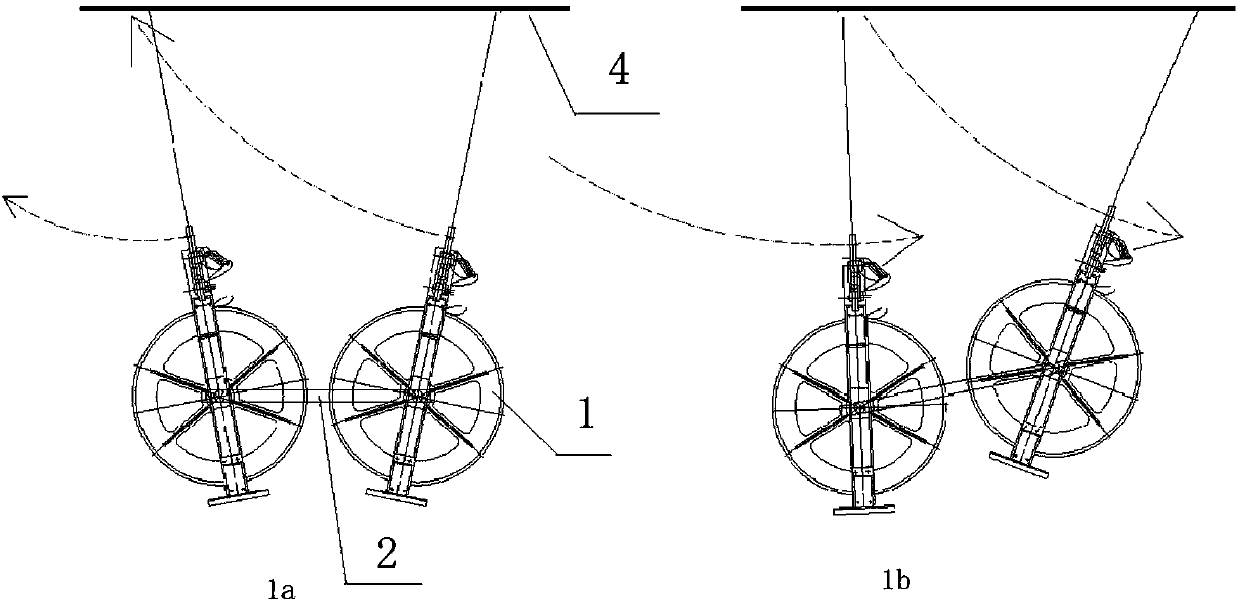

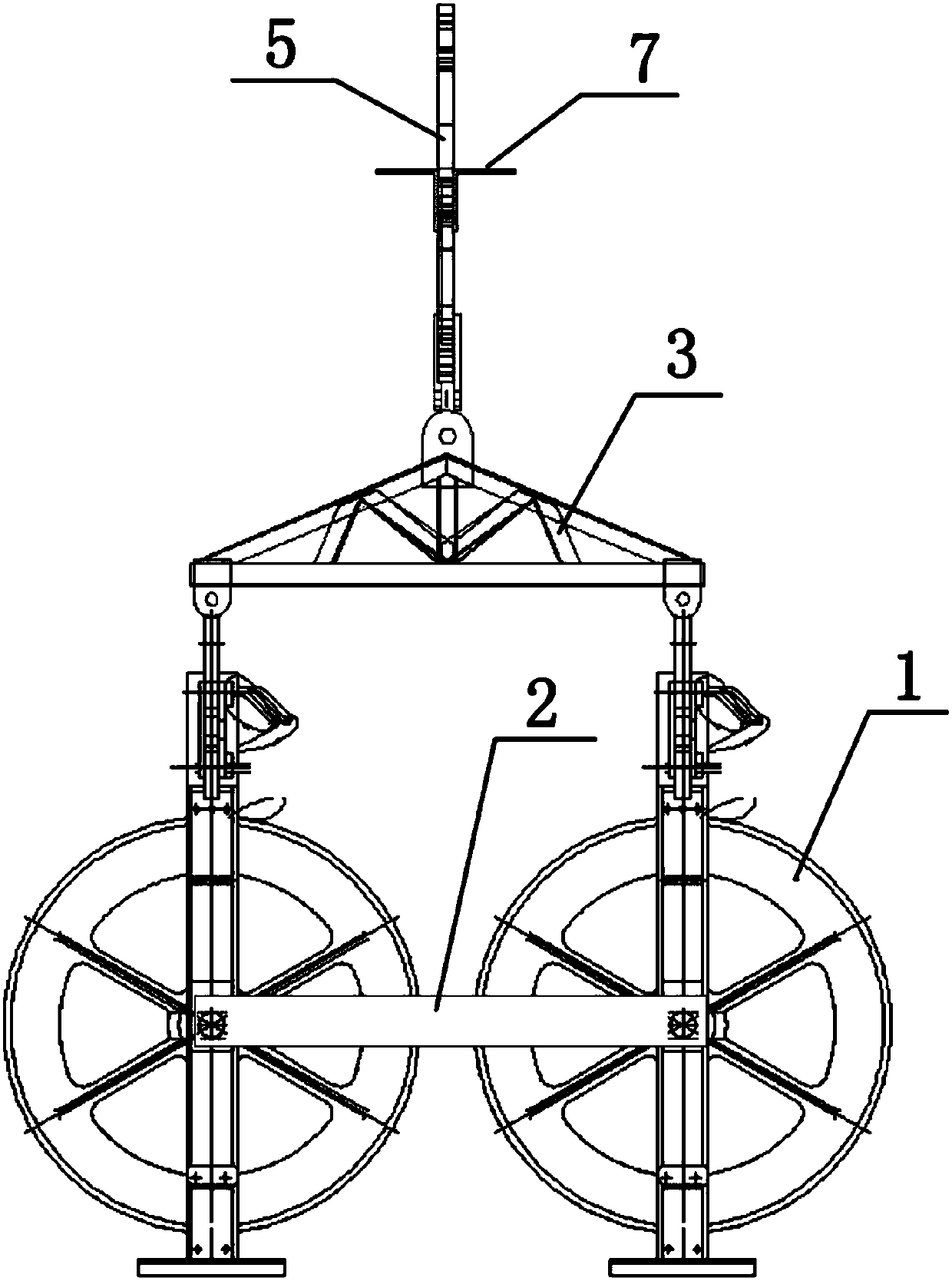

[0037] A double pulley hanger, comprising a support channel steel 2 connecting the wheel cores of two pulleys 1; it is characterized in that it also includes a frame body 3 connected to an iron tower cross arm 4, and the two pulleys 1 are respectively hinged on the frame The two ends of the bottom side of the frame body 3 and the middle part of the top side of the frame body 3 are connected to the iron tower cross arm 4 . The connection positions of the two pulleys 1 and the frame body 3 are symmetrically arranged along the position where the frame body 3 and the iron tower cross arm 4 are connected, such as Figure 2-Figure 4 shown.

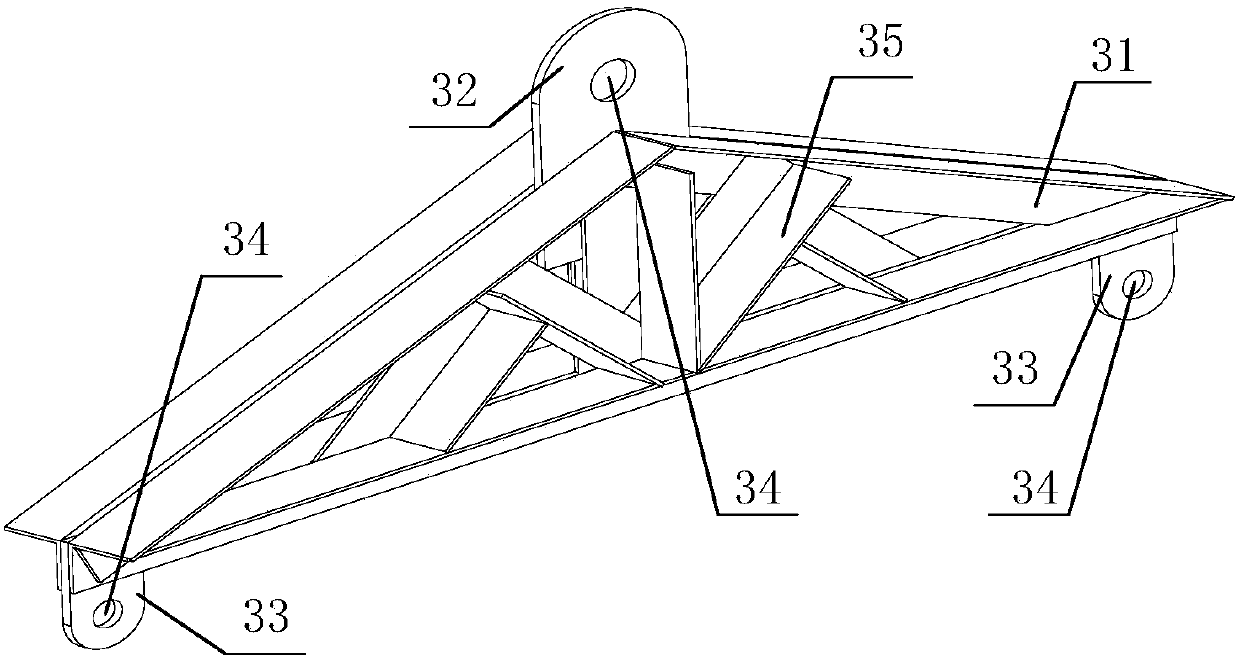

[0038] In this embodiment, the overall shape of the frame body 3 may be a rectangle, a square or a triangle. This embodiment takes a triangle as an example. This embodiment adopts the structural form of a triangular truss, which can give full play to the material properties, improve the connection stability and prolong the service life, and can...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is that, in this embodiment, a specific structure of a double tackle hanger is optimized, and the specific settings are as follows:

[0050] The angle of the top angle of the triangular body 31 is 90-160. In this embodiment, the angle of the apex of the triangular body 31 is preferably set to 150 degrees. Meanwhile, the frame body 3 is made of low-alloy steel, preferably Q345 steel in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com