Low-ventilation-air-methane-temperature mine ventilation-air-methane residual heat extraction system

A mine exhaust air extraction system technology is applied in the field of coal mine waste heat utilization system, which can solve the problems of equipment stability hindering development, easy dirty block heat exchange, and low freezing point.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

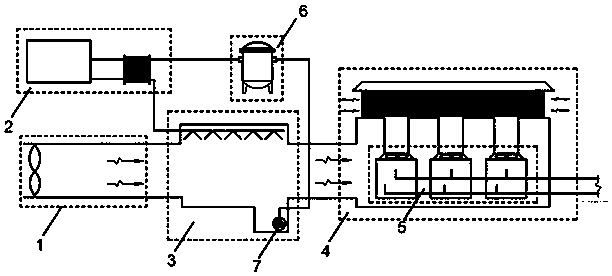

[0012] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following in conjunction with the attached figure 1 The low exhaust air temperature mine exhaust air waste heat extraction system is described in detail.

[0013] attached figure 1 Shown is the low exhaust air temperature mine exhaust heat extraction system, which consists of mine exhaust air duct 1, air compressor waste heat recovery system 2, mine exhaust air dust removal room 3, exhaust air heat exchange chamber 4, and air source heat pump System 5, filter system 6, and submersible pump 7. The mine exhaust air is discharged to the mine exhaust air dust removal room 3 through the mine exhaust air duct 1. The mine exhaust air dust removal room 3 is equipped with a spray dust removal device, and the water supply source of the spray dust removal The hot water recovered by the waste heat recovery system of the air compressor, the exhaust ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com