Test method of glass tank furnace batch mixture uniformity

A technology of glass tank kiln and test method, which is applied in measurement devices, analysis materials, material analysis using wave/particle radiation, etc., can solve problems such as time-consuming, single test components, and inability to meet production needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

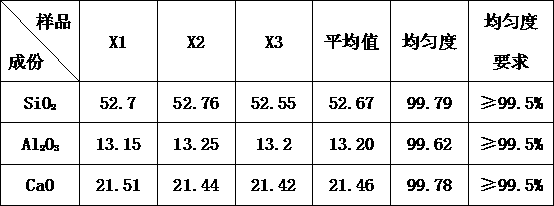

Embodiment 1

[0025] Test sample: glass tank kiln batch; production unit: Jushi Group Jiujiang Co., Ltd.; production date: 2017.6.30.

[0026] Test conditions: temperature 25°C, humidity 60%.

[0027] Test steps:

[0028] (1) Sampling: Sampling at the outlet of the glass kiln batch material storage tank, starting at 8:00, taking 1 kg of samples every 10 minutes, a total of 3 samples, marking the ziplock bag with a signature pen, and sending it to the experiment Room temperature adjustment.

[0029] (2) Sample preparation: On an analytical balance, use a platinum dry pot, weigh 7.002 grams of 67% anhydrous lithium tetraborate and 33% anhydrous lithium metaborate reagent, then weigh 0.701 grams of batch material samples, add 0.1 grams The release agent ammonium iodide. Mix the samples and reagents thoroughly with a plastic rod, and wipe the plastic rod with quantitative filter paper to avoid loss of samples and reagents.

[0030] (3) Melting sample: send the platinum dry pot to a melting ...

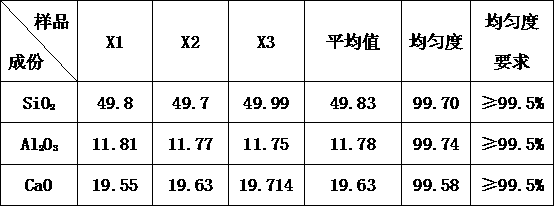

Embodiment 2

[0037] Test sample: glass tank kiln batch; production unit: Jushi Group Jiujiang Co., Ltd.; production date: 2017.7.25.

[0038] Test conditions: temperature 26°C, humidity 59%.

[0039] Test steps:

[0040] (1) Sampling: Sampling at the outlet of the glass kiln batch material storage tank, starting at 8:00, taking 1 kg of samples every 10 minutes, a total of 3 samples, marking the ziplock bag with a signature pen, and sending it to the experiment Room temperature adjustment.

[0041] (2) Sample preparation: On an analytical balance, use a platinum dry pot, weigh 7.005 grams of 67% anhydrous lithium tetraborate and 33% anhydrous lithium metaborate reagent, then weigh 0.707 grams of batch material samples, add 0.1 grams The release agent ammonium iodide. Mix the samples and reagents thoroughly with a plastic rod, and wipe the plastic rod with quantitative filter paper to avoid loss of samples and reagents.

[0042] (3) Melting sample: Send the platinum dry pot to a melting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com