Segmented prediction method and device for silicon content of melted iron of blast furnace

A blast furnace hot metal and prediction method technology, applied in special data processing applications, knowledge expression, instruments, etc., can solve problems such as large fluctuation prediction accuracy, redundant prediction model input sets, and incomplete selection of furnace conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0124] The present invention will be further described below in conjunction with examples. In this embodiment, the 2650m of a domestic iron and steel plant 3 Take the actual blast furnace production data collected from January 1, 2015 to June 1, 2015 as an example.

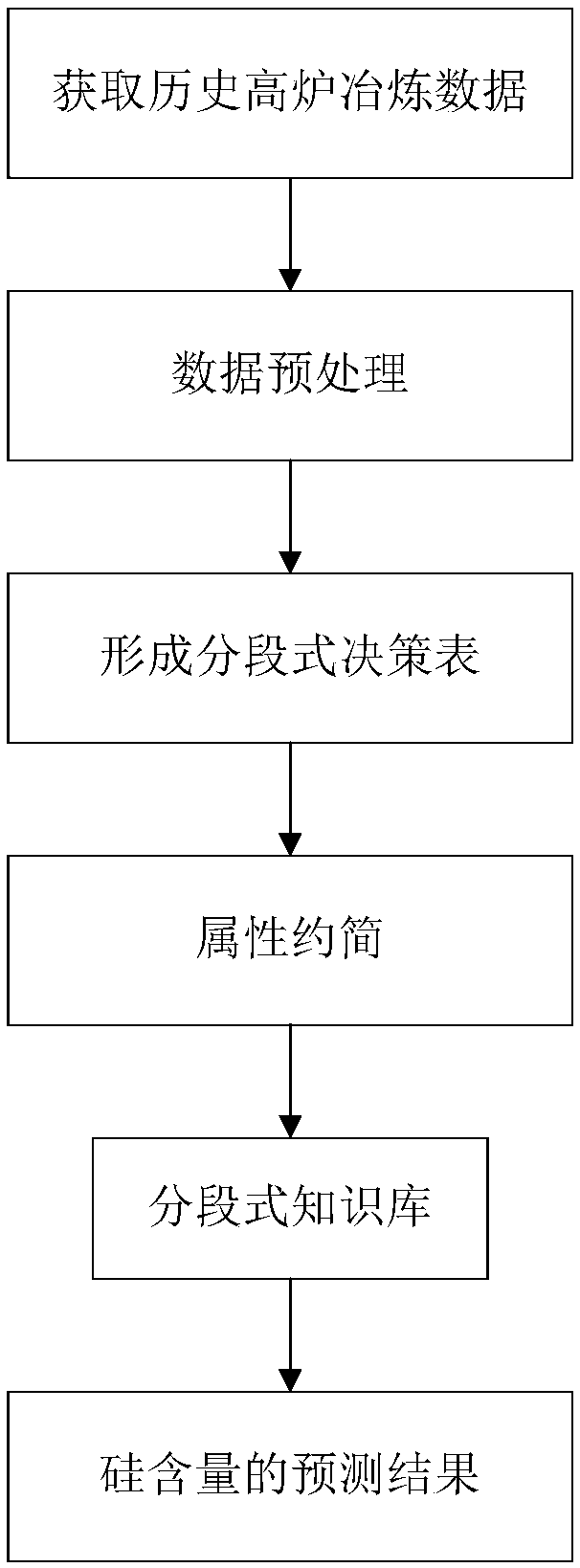

[0125] Such as figure 1 As shown, in this embodiment, a method for predicting the silicon content of molten iron in a segmented blast furnace includes the following steps:

[0126] Step 1: Obtain historical blast furnace smelting data, and use the acquired historical blast furnace smelting data as sample data;

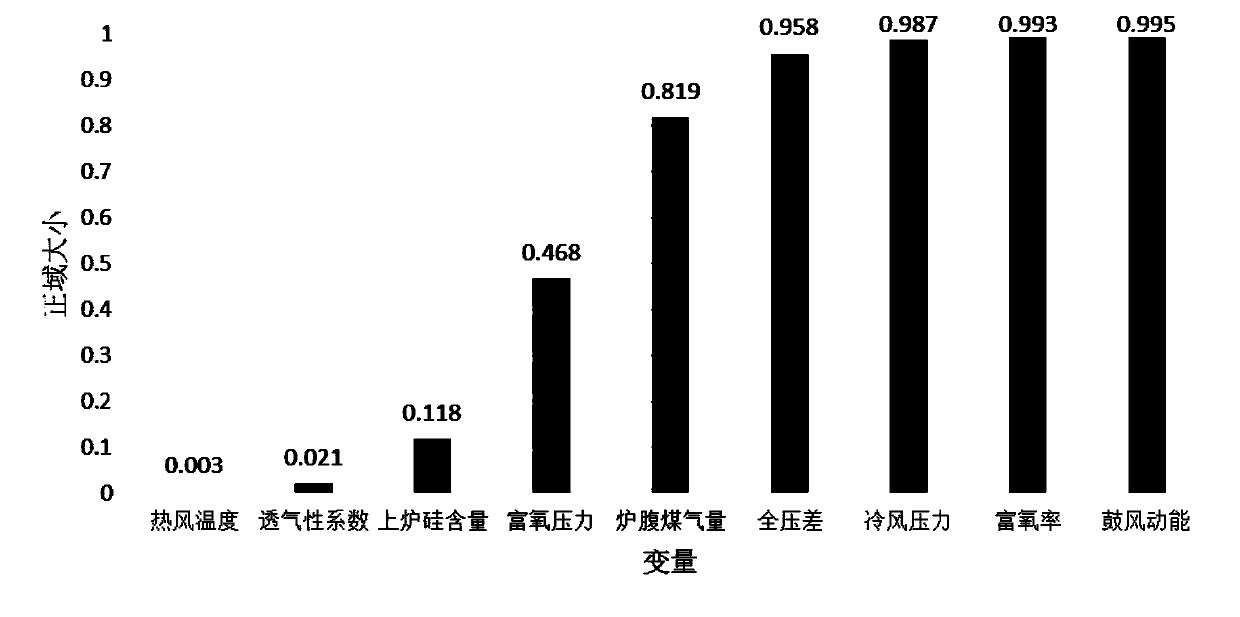

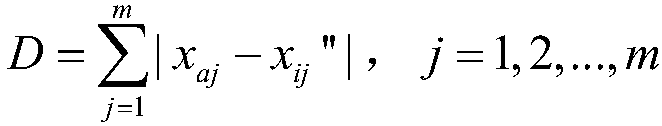

[0127] In this embodiment, the blast furnace smelting data includes condition attribute data and decision attribute data, wherein the decision value of the decision attribute data is silicon content, and the condition attribute data includes oxygen enrichment rate, air permeability index, standard wind speed, cold air flow rate, and blast kinetic energy , bosh gas volume, bosh gas index, theoretical com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com