Pixel defining layer, preparation method thereof, and display panel

A pixel-defining layer and pixel-defining technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems affecting the light-emitting effect of the OLED light-emitting layer, affecting the life of the display device, and uneven thickness of the OLED light-emitting layer. , to achieve the effect of improving the light-emitting effect, increasing the life, and improving the uniformity of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present application provide a pixel defining layer, a preparation method thereof, and a display panel, which are used to improve the film thickness uniformity of the OLED light-emitting layer, improve the light extraction effect of the OLED light-emitting layer, and increase the life of the display device.

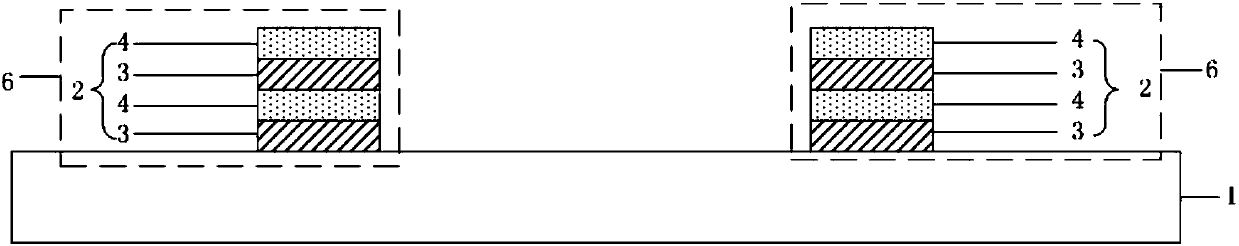

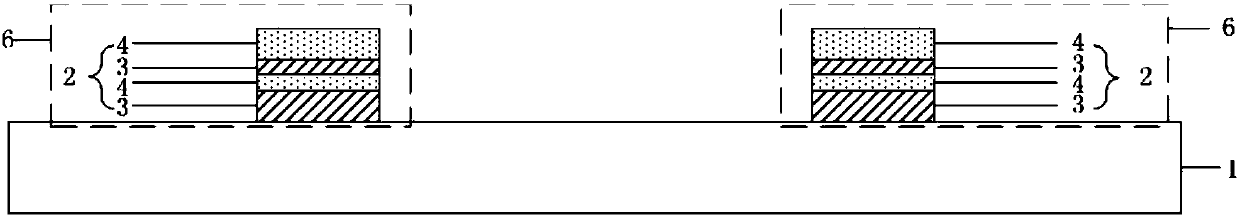

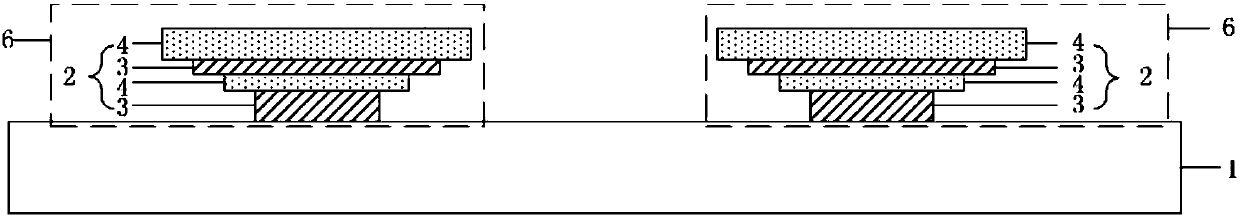

[0030] A pixel definition layer provided by the embodiment of the present application, such as figure 1 As shown, the pixel defining layer 6 is disposed on the substrate 1, and the pixel defining layer 1 includes: on the substrate 1, at least four layers of pixel defining layers are alternately stacked by hydrophilic pixel defining layers 3 and hydrophobic pixel defining layers 4. Layer 2; the pixel defining sublayer 2 adjacent to the substrate 1 is a hydrophilic pixel defining layer 3, and in the direction perpendicular to the substrate 1, the pixel defining sublayer 2 farthest from the substrate 1 is a hydrophobic pixel defining layer 4

[0031...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com