Scanning probe microscope

A probe microscope and scanning type technology, applied in the field of scanning probe microscope, can solve the problems of difficult to intuitively understand the adjustment of the position of the mark, and achieve the effect of simple optical axis adjustment, reducing deviation and reducing burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

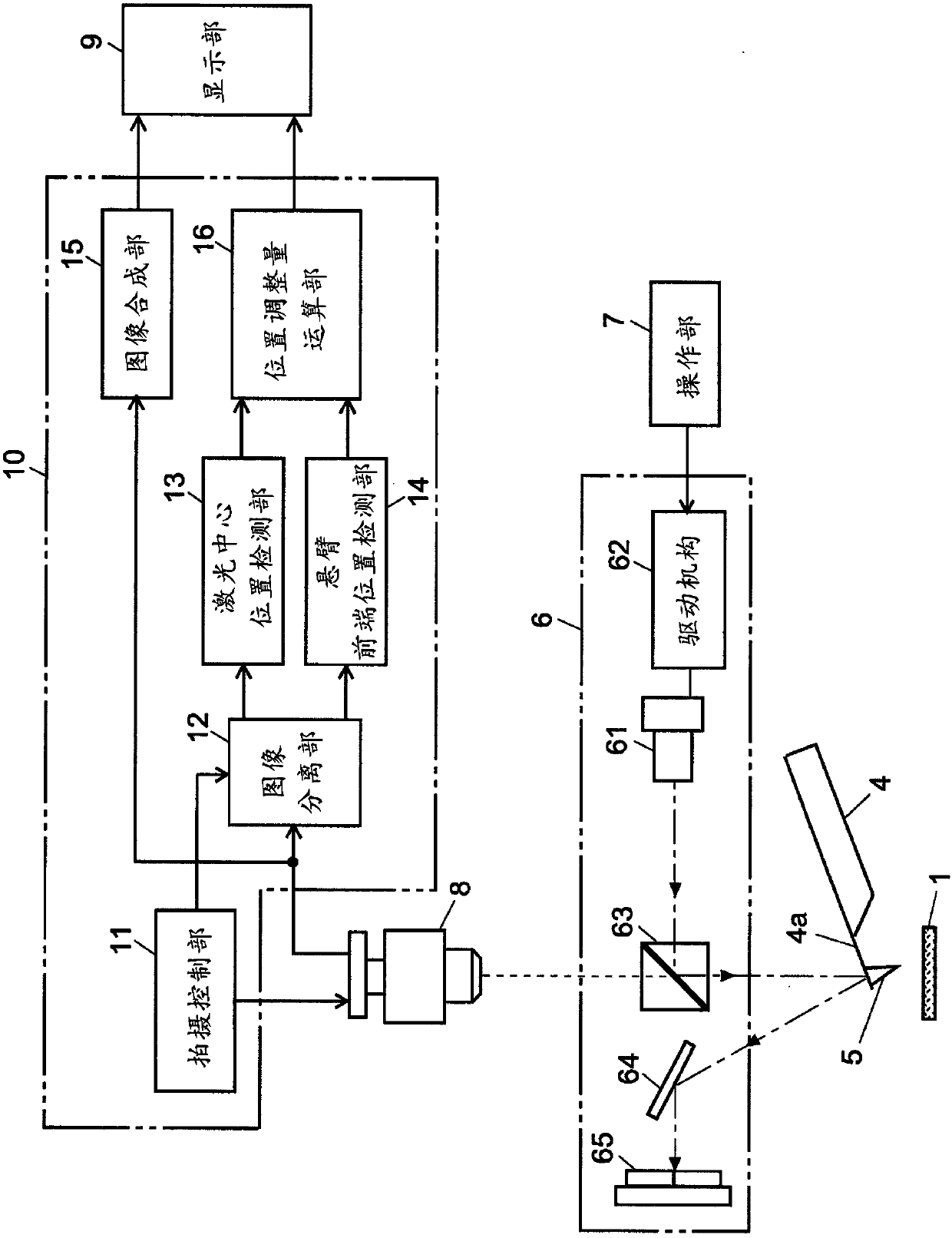

[0045] Hereinafter, a scanning probe microscope, which is an embodiment of the present invention, will be described with reference to the drawings. figure 1 It is a configuration diagram of main parts of the scanning probe microscope of this embodiment. right with Figure 7 The same components as those shown in the conventional scanning probe microscope are assigned the same reference numerals, and detailed descriptions thereof are omitted.

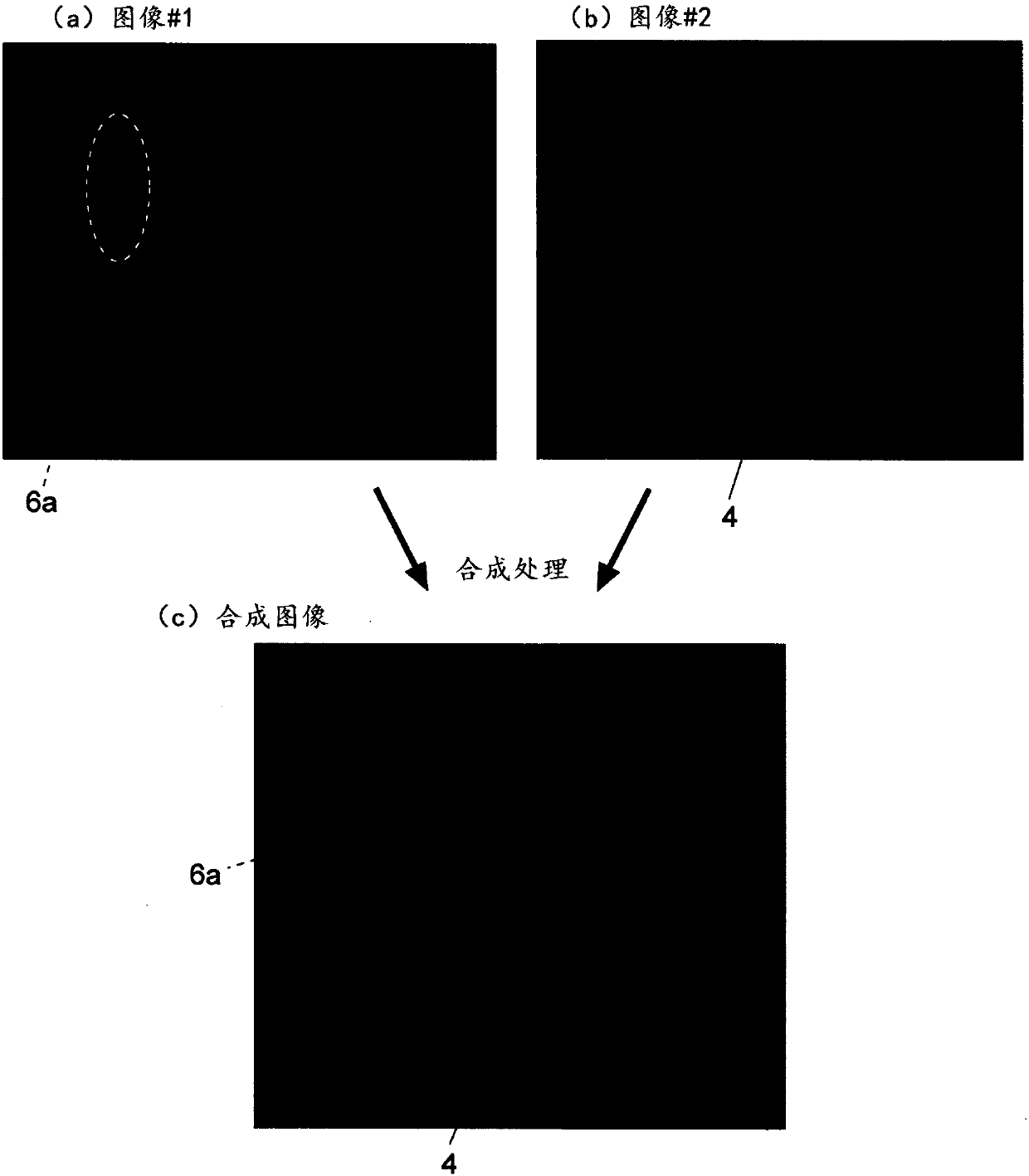

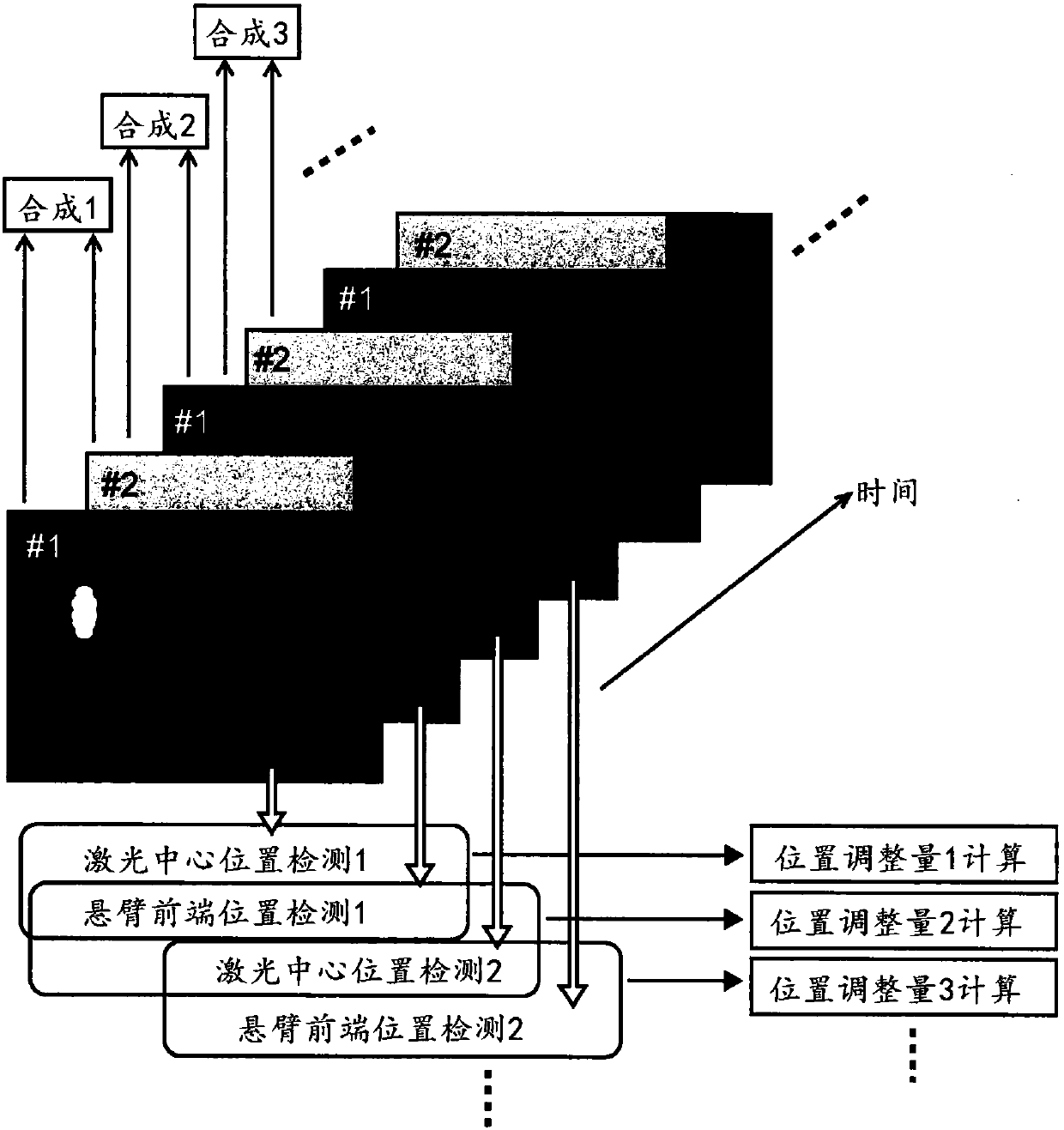

[0046] The scanning probe microscope of the present embodiment includes an optical axis adjustment control and processing unit 10 that controls the camera 8 and controls the camera 8 as a component that is not included in the conventional device. A function for processing image data captured by the camera 8 . The optical axis adjustment control and processing unit 10 includes an imaging control unit 11, an image separation unit 12, a laser center position detection unit 13, a cantilever front end position detection unit 14, an image syn...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap