Grinding liquid stirring device

A stirring device and a technology for grinding liquid, which are applied in the field of semiconductor integrated circuit manufacturing, and can solve the problems of affecting the chemical stability of grinding liquid, low stirring efficiency of stirring blades, and rising temperature of grinding liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

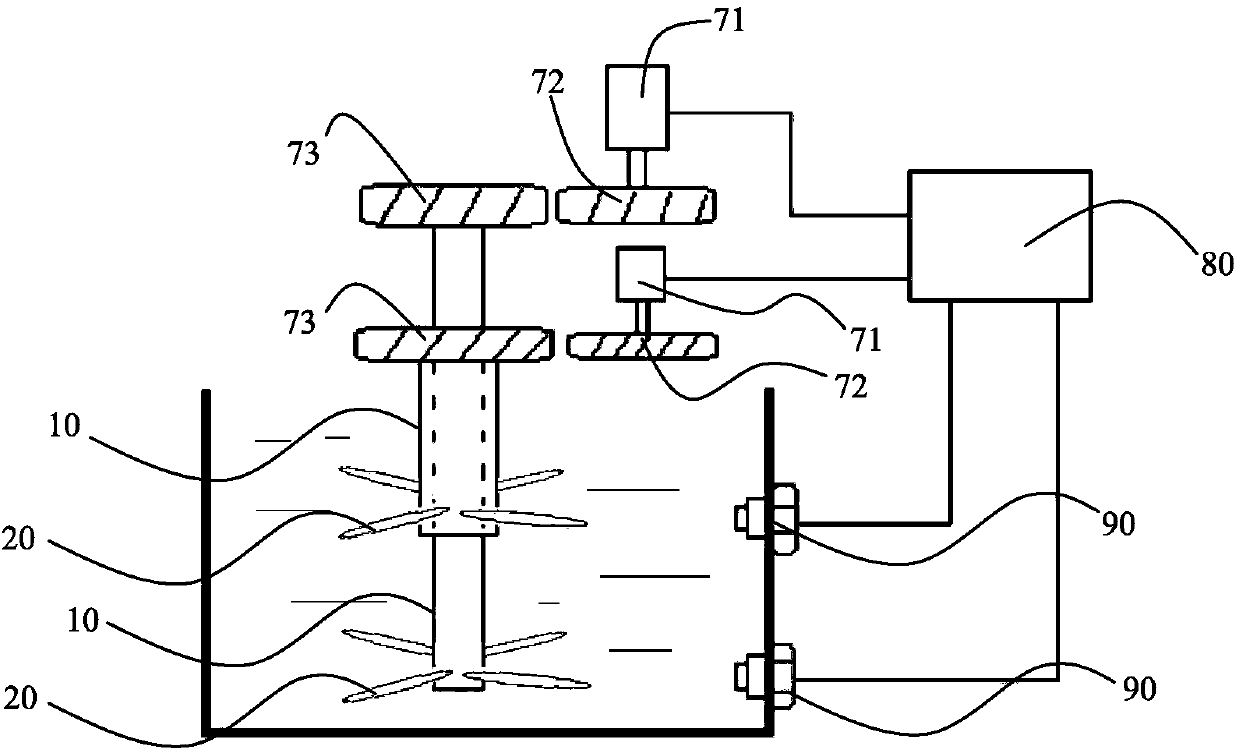

[0031] Such as figure 2 As shown, the grinding liquid stirring device of the present invention includes a stirring barrel 60 , two sets of stirring blades 20 , two stirring shafts 10 , two stirring shaft drive assemblies, a stirring control unit 80 and a liquid level sensor 90 . The stirring blades 20 are arranged in the mixing bucket 60; each stirring shaft 10 is fixedly connected with the stirring blades respectively, and the stirring shafts are concentric; two stirring shaft drive assemblies respectively drive the two stirring shafts to rotate; The control unit 80 controls the start and stop of the stirring shaft drive assembly according to preset conditions. The liquid level sensor 90 is used to sense the height of the liquid and transmit the signal to the stirring control unit 80 . The stirring control unit 80 controls the start and stop of the stirring shaft driving assembly according to the relationship between the liquid level of the grinding liquid in the stirring b...

Embodiment 2

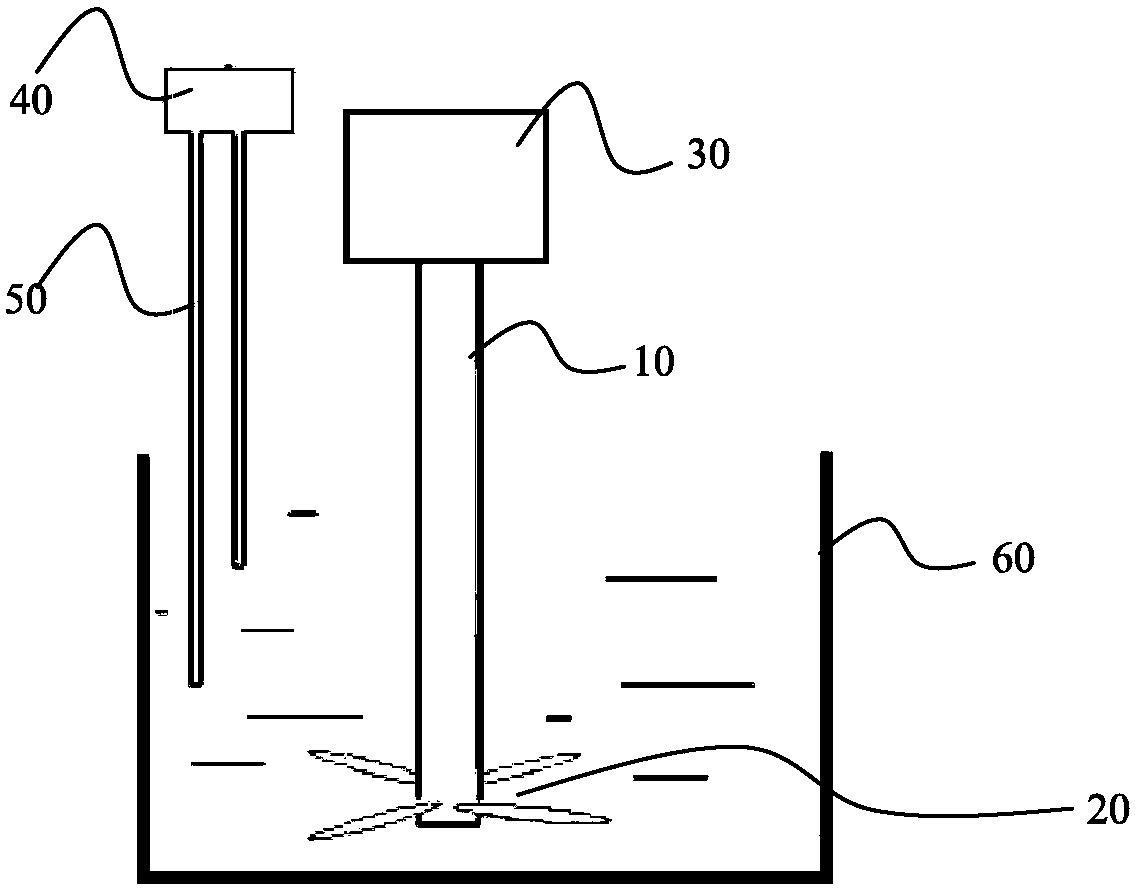

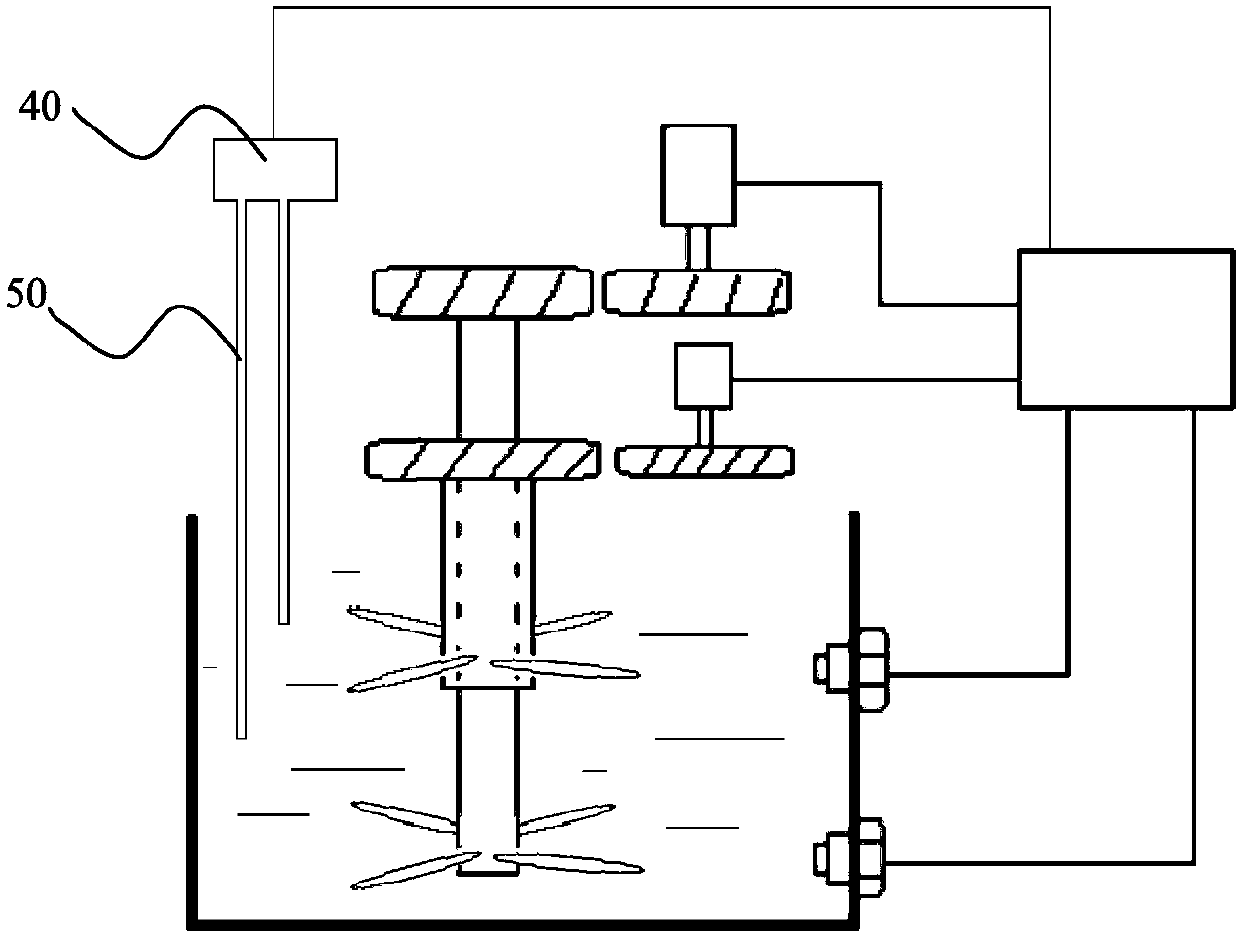

[0035] Such as image 3 Shown is another embodiment of the grinding liquid stirring device of the present invention. On the basis of Embodiment 1, a grinding liquid circulation device is added, which includes a grinding liquid circulation pump 40 and a circulation pipe 50 inserted in the grinding liquid, and the grinding liquid stirring device always works to maintain the self-circulation of the grinding liquid.

Embodiment 3

[0037] Such as Figure 5 Shown is another embodiment of the grinding liquid stirring device of the present invention. It includes a stirring bucket 60, three sets of stirring blades 20, three stirring shafts 10, three stirring shaft drive assemblies, a stirring control unit 80 and a liquid level sensor 90. The stirring blades 20 are arranged in the mixing bucket 60; each stirring shaft 10 is fixedly connected with the stirring blades respectively, and the stirring shafts are concentric; the three stirring shaft drive assemblies respectively drive the three stirring shafts to rotate; the stirring control A unit 80 controls the start and stop of the stirring shaft driving assembly according to preset conditions. The liquid level sensor 90 is used to sense the height of the liquid and transmit the signal to the stirring control unit 80 . The stirring control unit 80 controls the start and stop of the stirring shaft driving assembly according to the relationship between the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com