Assembled simple support box beam structure of PVA fiber cement base composite material and manufacturing method

A fiber cement, composite material technology, applied in bridges, manufacturing tools, ceramic molding machines, etc., to achieve the effect of enhancing durability, improving ductility, and improving crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

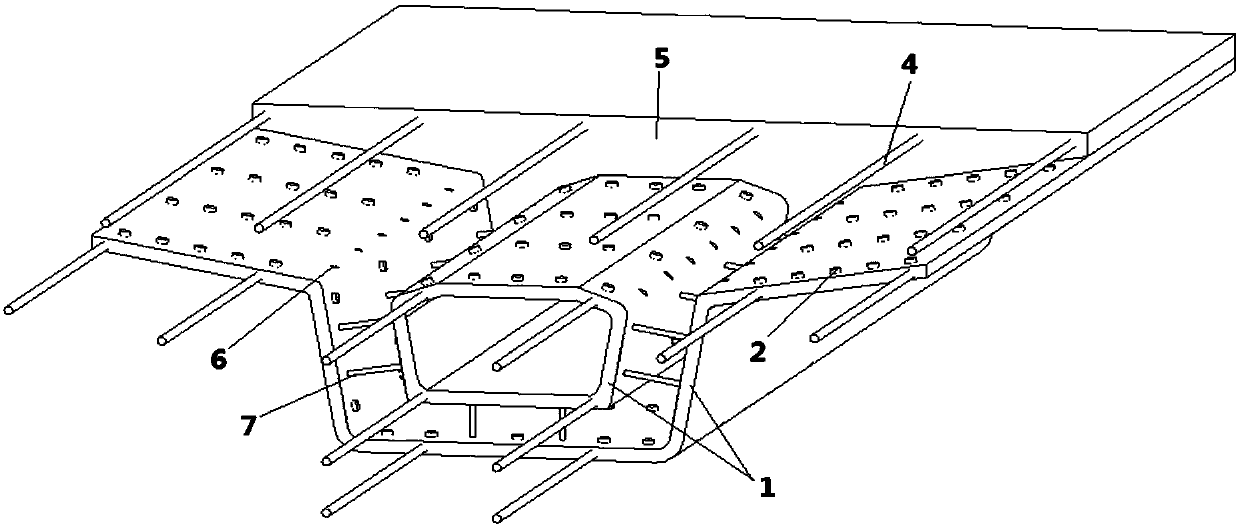

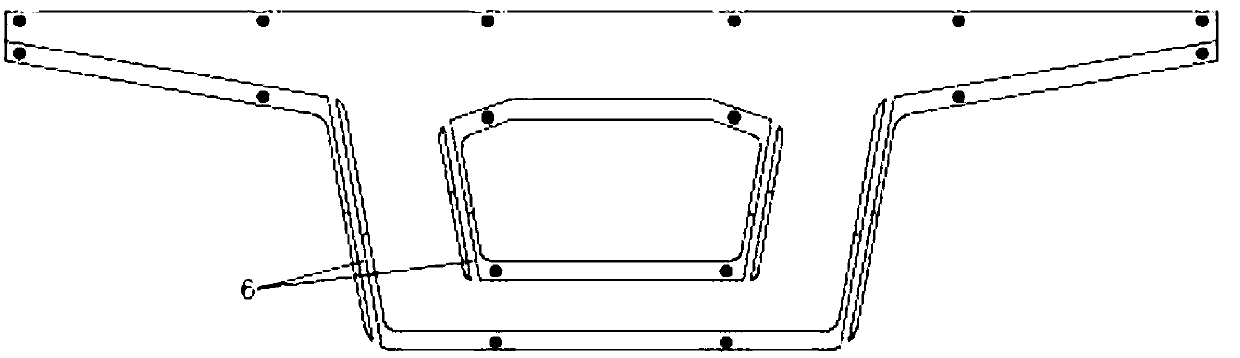

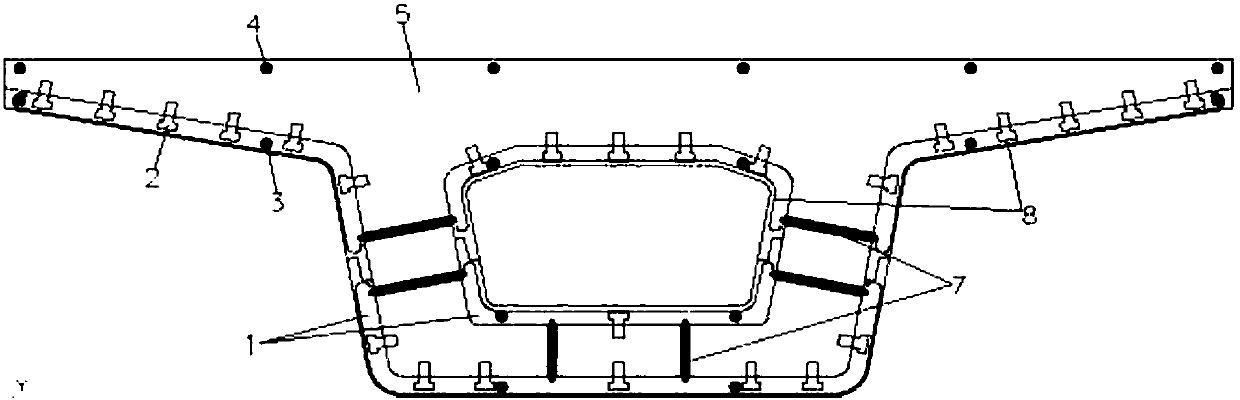

[0031] Such as Figure 1-5 As shown, a prefabricated simply supported box girder structure of PVA fiber cement-based composite material, including outer cladding and inner lining 1, embedded parts 2, tensile steel bars 3, stirrups 8, bellows 6, telescopic Steel pipe 7, ordinary concrete 5, compression steel bar 4 and prestressed tendons;

[0032] The outer cladding layer and the inner lining layer 1 are spliced by PVA fiber cement-based composite material board sections; the mix ratio of the PVA fiber cement-based composite material is: cement 380kg / m 3 , Class I high calcium fly ash 910kg / m 3 , water 330kg / m 3 , quartz sand 455kg / m 3 , the water reducer accounts for 4.71% of the cement mass, the foaming agent accounts for 1.57% of the sum of the cement and Class I high-calcium fly ash, and the PVA fiber accounts for 1.88% of the total vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com