A portable ground wire winding device

A winding device and grounding wire technology, which is applied in the field of electric power construction equipment, can solve problems such as threatening the safety of maintenance operators, irregular storage, and scattering, so as to shorten the time for installing the grounding wire, improve the efficiency of storage, and improve the construction efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

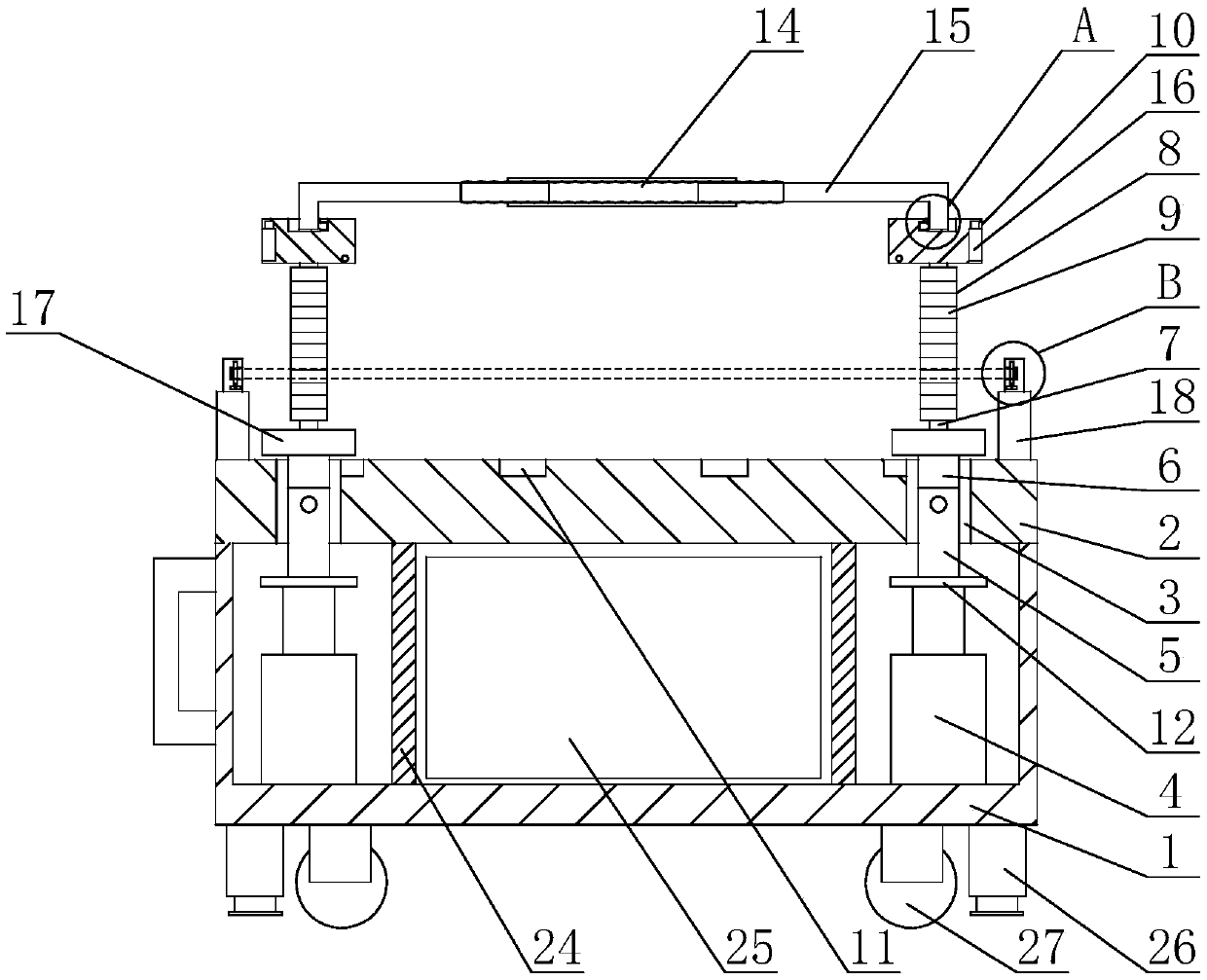

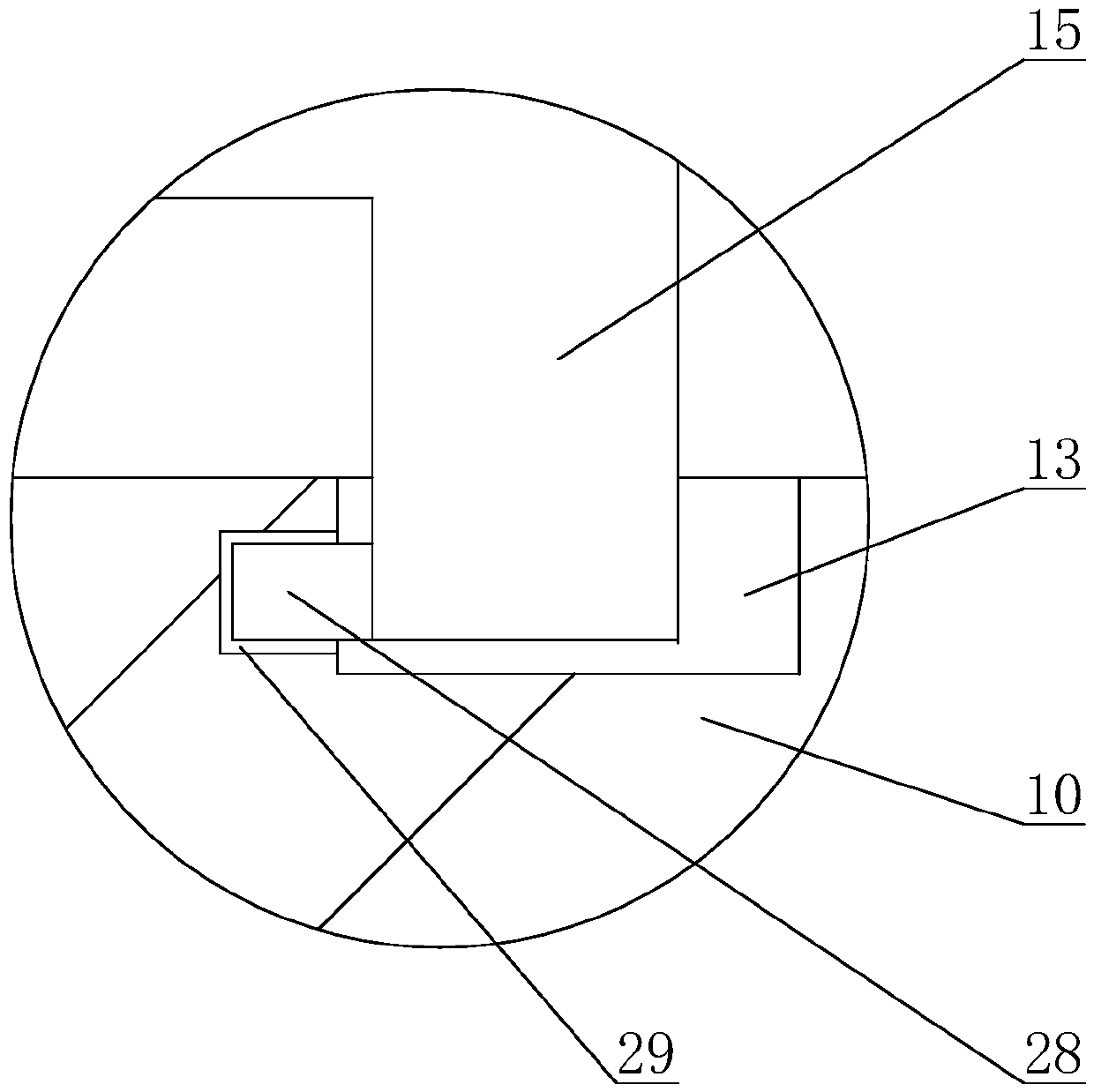

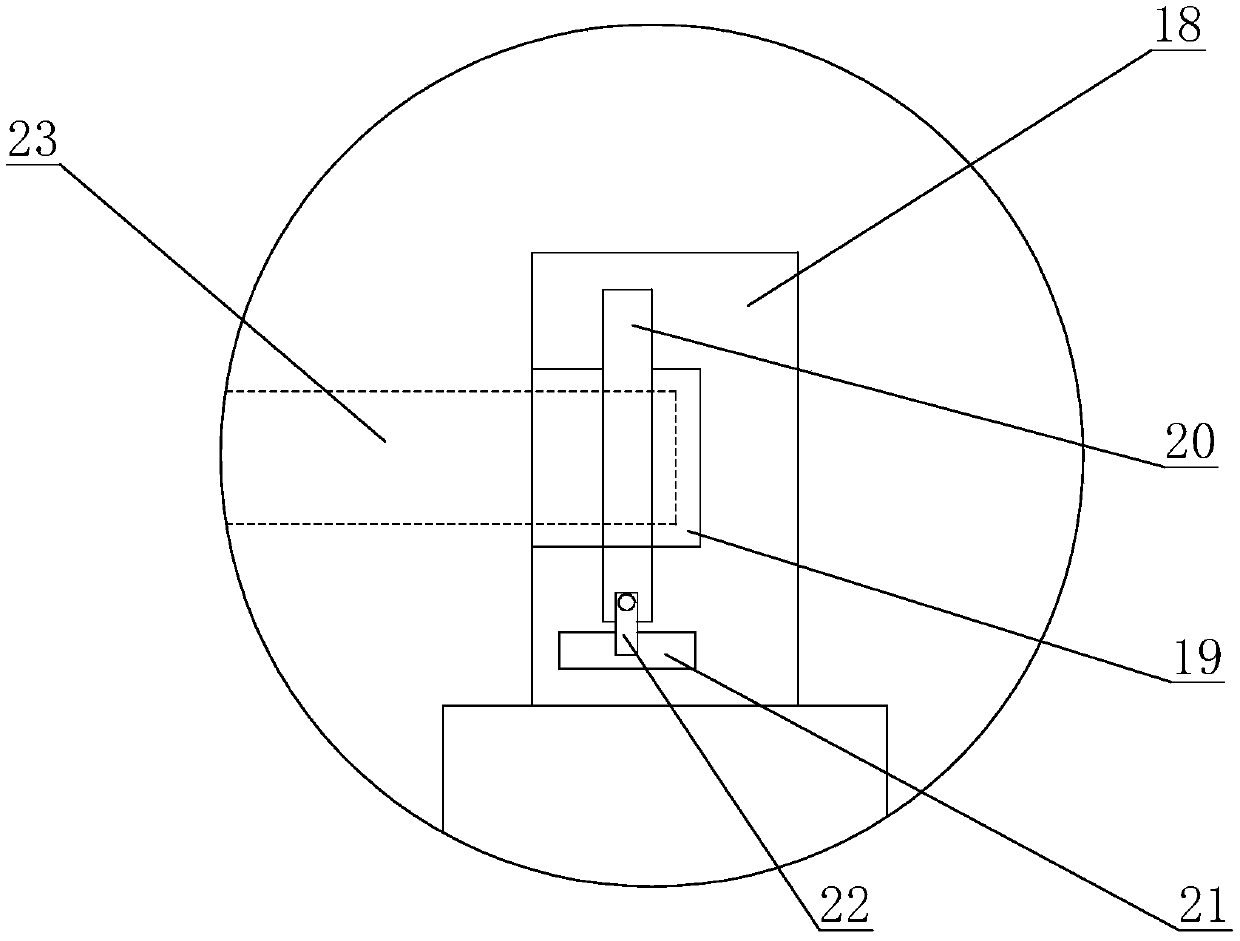

[0043]A portable grounding wire winding device, including a U-shaped base 1 with an upward opening, a hook ring for pulling the device is provided on the outer wall of the base, and a telescopic rod 26 is provided at the bottom of the base 1, and the telescopic rod can be controlled by a single-chip microcomputer. , the bottom of the bottom wall is provided with a moving wheel 27. When the telescopic rod 26 is retracted, the distance between the bottom of the telescopic rod 26 and the bottom wall of the base 1 is less than the distance between the end of the moving wheel 27 and the bottom wall of the base 1 in contact with the ground. The opening of the base 1 is provided with a cover plate 2 compatible with the base 1, which can be realized by bolt connection or one end hinged and the other end buckled. The cover plate is a cover plate with a certain thickness, and the base 1 and Two support plates 24 parallel to each other are arranged between the cover plates 2, which can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com