Automatic solvent replacing apparatus in preparation process of hydrophobic silicon dioxide aerogel

A technology of silica and solvent replacement, applied in inorganic chemistry, silicon compounds, chemical instruments and methods, etc., can solve the problems of long time consumption, repeated solvent replacement, and the solvent loss rate cannot be minimized, and achieves low solvent loss, Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

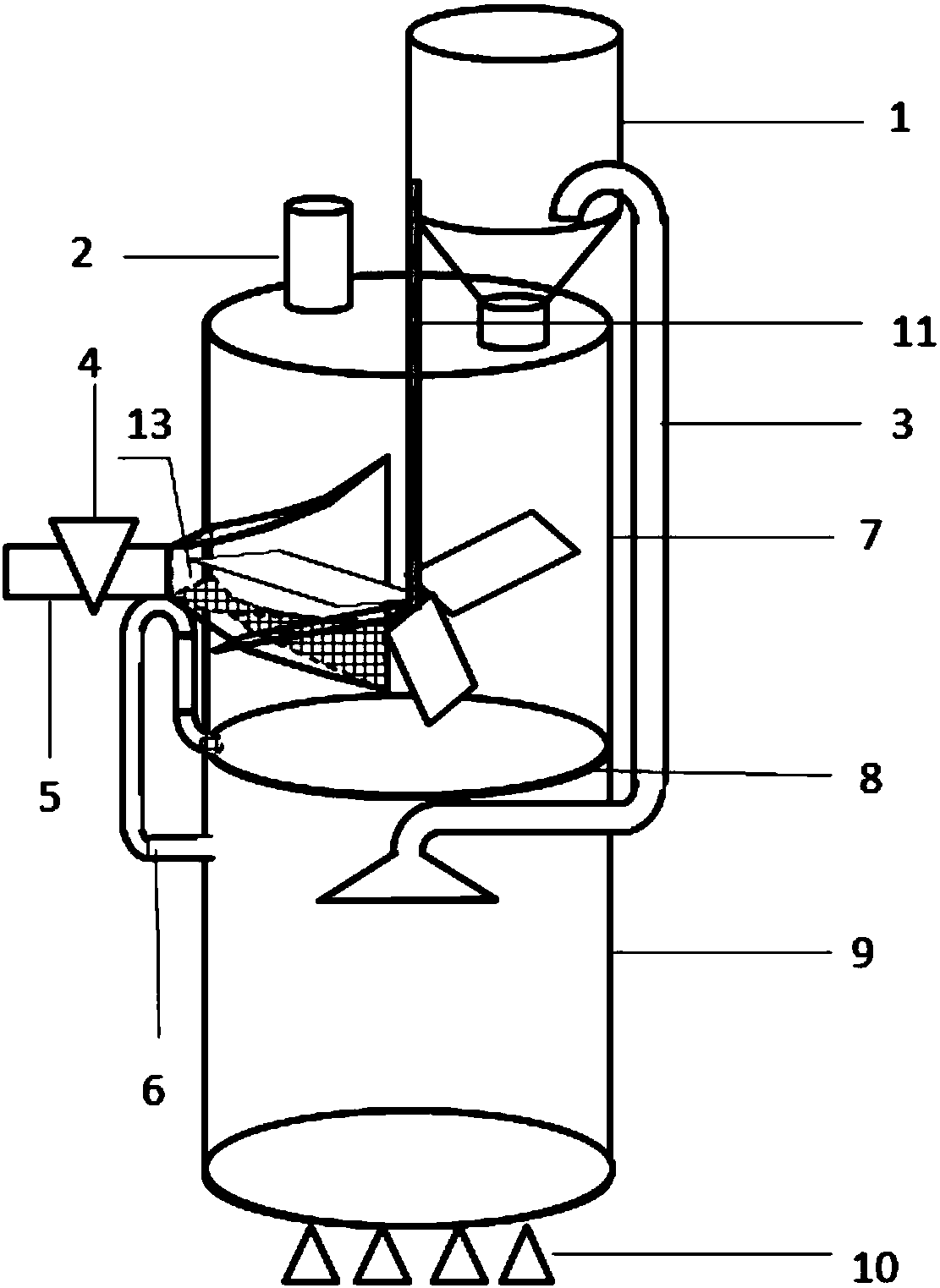

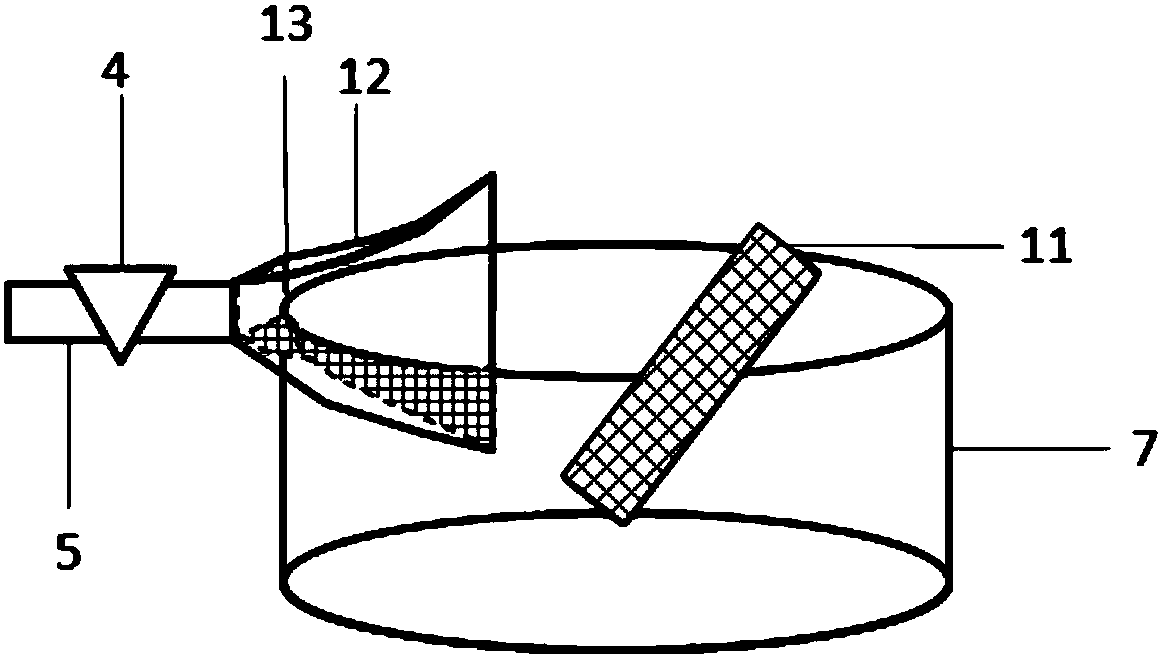

[0031] Such as figure 1 This embodiment is a schematic diagram of the device for automatically replacing the solvent during the preparation process of the hydrophobic silica aerogel. The device includes a cylindrical reactor with a condenser 1 installed on the cylindrical reactor. The cylindrical reactor is divided into upper and lower layers. The upper layer is used for displacement reaction, the lower layer is used to place the recovered solvent, and the upper and lower layers are used for condensation. The recirculation pipe 6 and the steam pipe 3 form a circulation loop between the devices 1;

[0032] The reflux pipe 6 is a bent pipe with a siphon effect. It is installed at the bottom of the upper layer of the reactor and the top of the lower layer to connect the bottom of the upper layer and the lower layer. When the solvent of the displacement reaction reaches the top of the reflux pipe, the liquid in the upper layer of the reactor will automatically flow to the reaction. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com