Preparation method of buton rock asphalt-modified asphalt mixture

An asphalt mixture and asphalt modification technology, applied in the field of asphalt preparation, can solve the problems of material waste, complex production process, unfavorable small-scale pavement application, etc., and achieve the effect of low raw material, simple preparation method and improved high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

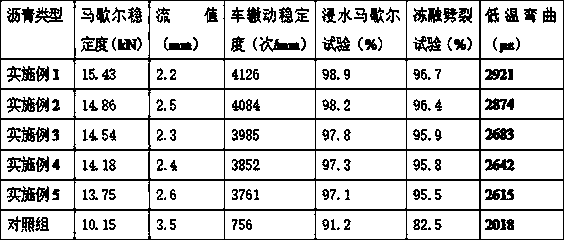

Examples

Embodiment 1

[0021] A preparation method of Buton rock asphalt modified asphalt mixture, comprising the following steps:

[0022] (1) Heat 70# base asphalt to 180°C;

[0023] (2) Add Buton rock asphalt to the heated 70# base asphalt in step (1), maintain it at 185°C for 1.5 hours and then stir for 30 minutes to obtain rock asphalt modified asphalt;

[0024] (3) Add gravel to the asphalt-modified asphalt prepared in step (2), and continue shearing at 190°C for 2 hours, so that the gravel is evenly dispersed in the asphalt-modified asphalt;

[0025] (4) Add mineral powder and graphite oxide to the product obtained in step (3) and mix to prepare Buton rock asphalt modified asphalt mixture.

[0026] Preferably, the gravel is limestone.

[0027] Preferably, the addition of Butonite asphalt in the step (2) is 15% of the base asphalt.

[0028] Preferably, the addition of sand powder and graphite oxide in the step (4) is respectively 10% and 5% of the mixture before adding.

Embodiment 2

[0030] A preparation method of Buton rock asphalt modified asphalt mixture, comprising the following steps:

[0031] (1) Heat 70# base asphalt to 175°C;

[0032] (2) Add Buton rock asphalt to the heated 70# base asphalt in step (1), maintain it at 175°C for 1 hour and then stir for 20 minutes to obtain rock asphalt modified asphalt;

[0033] (3) Add gravel to the asphalt-modified asphalt prepared in step (2), and continue shearing at 180°C for 1 hour, so that the gravel is evenly dispersed in the asphalt-modified asphalt;

[0034] (4) Add mineral powder and graphite oxide to the product obtained in step (3) and mix to prepare Buton rock asphalt modified asphalt mixture.

[0035] Preferably, the gravel is basalt.

[0036] Preferably, the addition of Butonite asphalt in the step (2) is 10% of the base asphalt.

[0037] Preferably, the addition of sand powder and graphite oxide in the step (4) is respectively 5% and 3% of the mixture before adding.

Embodiment 3

[0039] A preparation method of Buton rock asphalt modified asphalt mixture, comprising the following steps:

[0040] (1) Heat 90# base asphalt to 190°C;

[0041] (2) Add Buton rock asphalt to the heated 90# base asphalt in step (1), maintain it at 190°C for 2 hours and then stir for 40 minutes to obtain rock asphalt modified asphalt;

[0042] (3) Add gravel to the asphalt-modified asphalt prepared in step (2), and continue shearing at 200°C for 3 hours, so that the gravel is evenly dispersed in the asphalt-modified asphalt;

[0043] (4) Add mineral powder and graphite oxide to the product obtained in step (3) and mix to prepare Buton rock asphalt modified asphalt mixture.

[0044] Preferably, the gravel is diabase.

[0045] Preferably, the addition of Butonite asphalt in the step (2) is 20% of the base asphalt.

[0046] Preferably, the addition of sand powder and graphite oxide in the step (4) is respectively 15% and 8% of the mixture before adding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com