Electric pressure cooker insulation cover pottery device and pottery method

An electric pressure cooker and pottery technology, applied in the direction of metal material coating process, etc., can solve the problems of heavy metal pollution of the environment, complex equipment, etc., to improve the oil removal effect and efficiency, improve the effect and efficiency, and improve the rinsing effect and efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

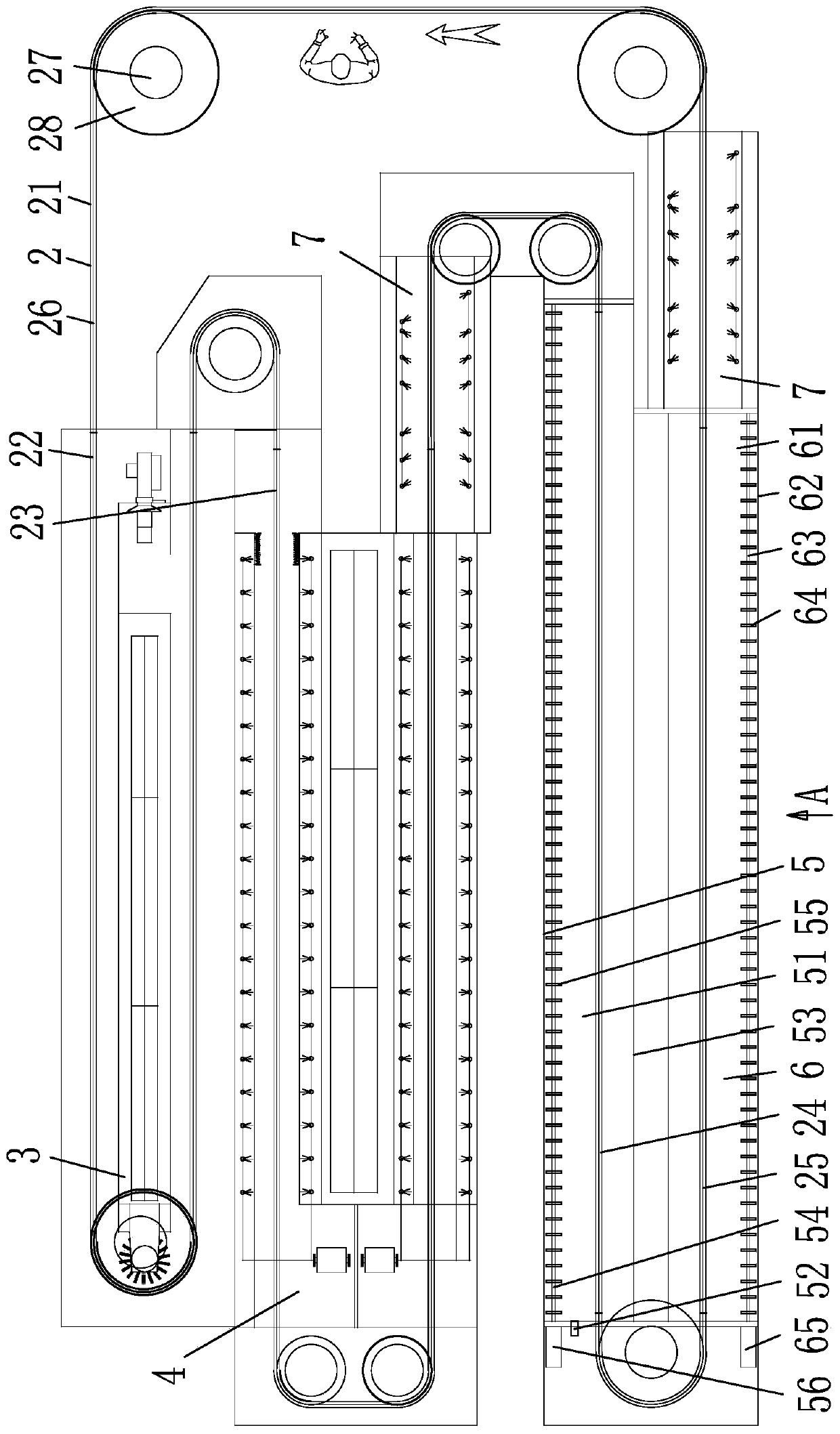

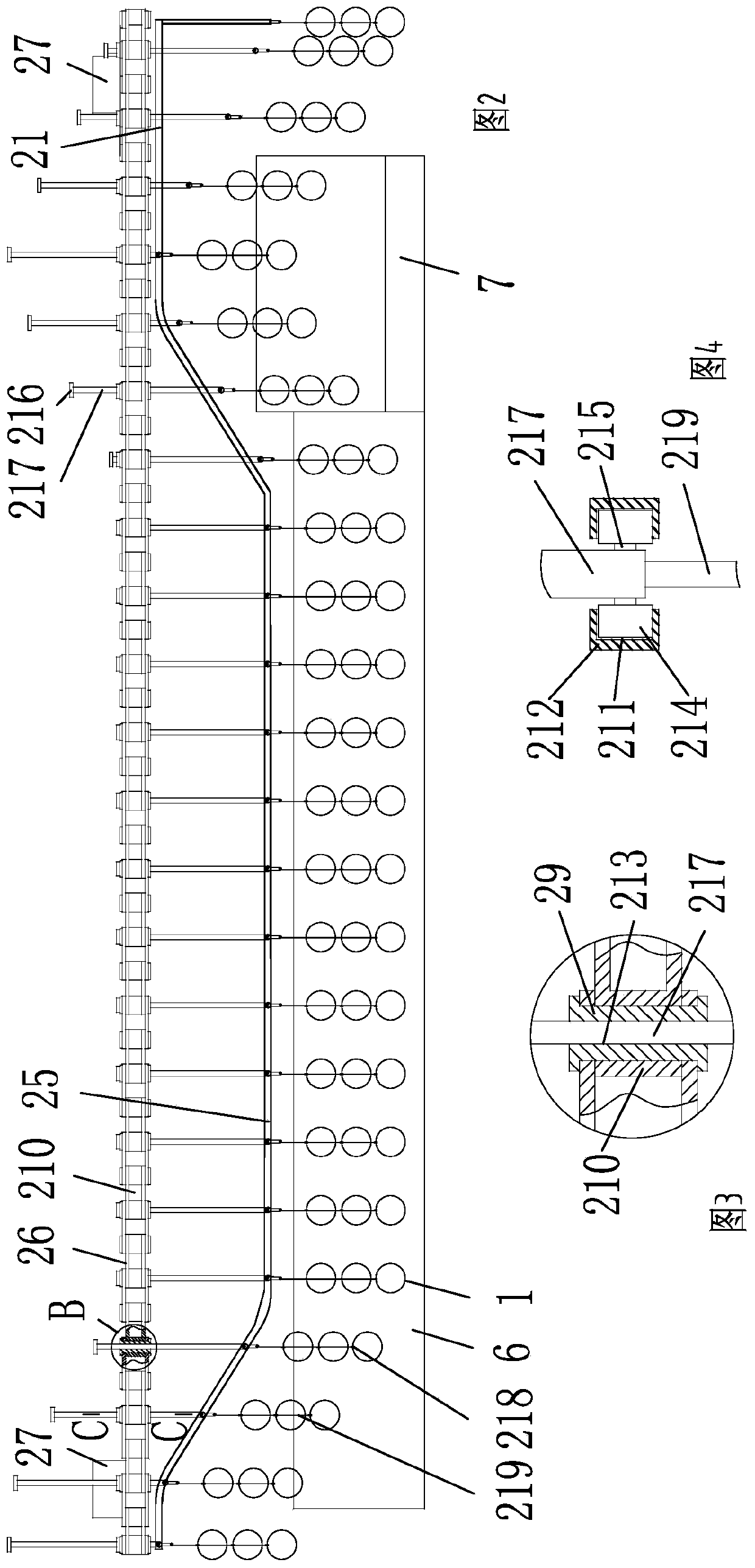

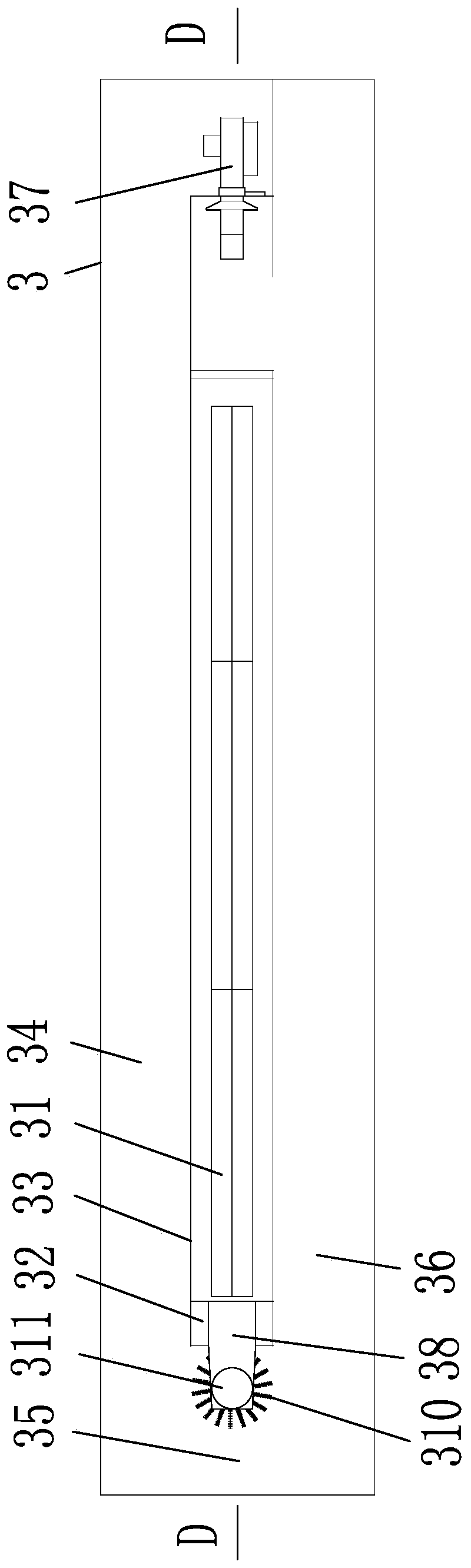

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] as attached figure 1 to attach Figure 9 Shown: a pottery device for electric pressure cooker heat preservation cover, comprising: a chain-type suspension conveyor 2 provided with a closed track 21 and a plurality of delivery hooks, a hot-dip degreasing device 3 arranged on the lower side of the closed track 21, warm water Decontamination device 4, ceramic device 5, rinse device 6, two spray cleaning devices 7; one spray cleaning device 7 is located between warm water decontamination device 4 and ceramic device 5; another spray cleaning device 7 is located Rinsing device 6 rear side.

[0028] The heat-dipping degreasing device 3 includes: a heat-dipping degreasing tank body 33 provided with a degreasing heater 31 and a degreasing temperature control switch 32; , the transition degreasing tank 35 and the rear degreasing tank 36 arranged side by side with the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com