Aluminum frame anode for changing anode current circuit

A technology of anode current and anode bus, which is applied in the field of aluminum electrolysis, can solve the problems of complex structure of anode bus, complex structure of electrolytic cell, and many restrictions on process operation, and achieve the effect of simplifying structure, simplifying structure and configuration, and simplifying process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

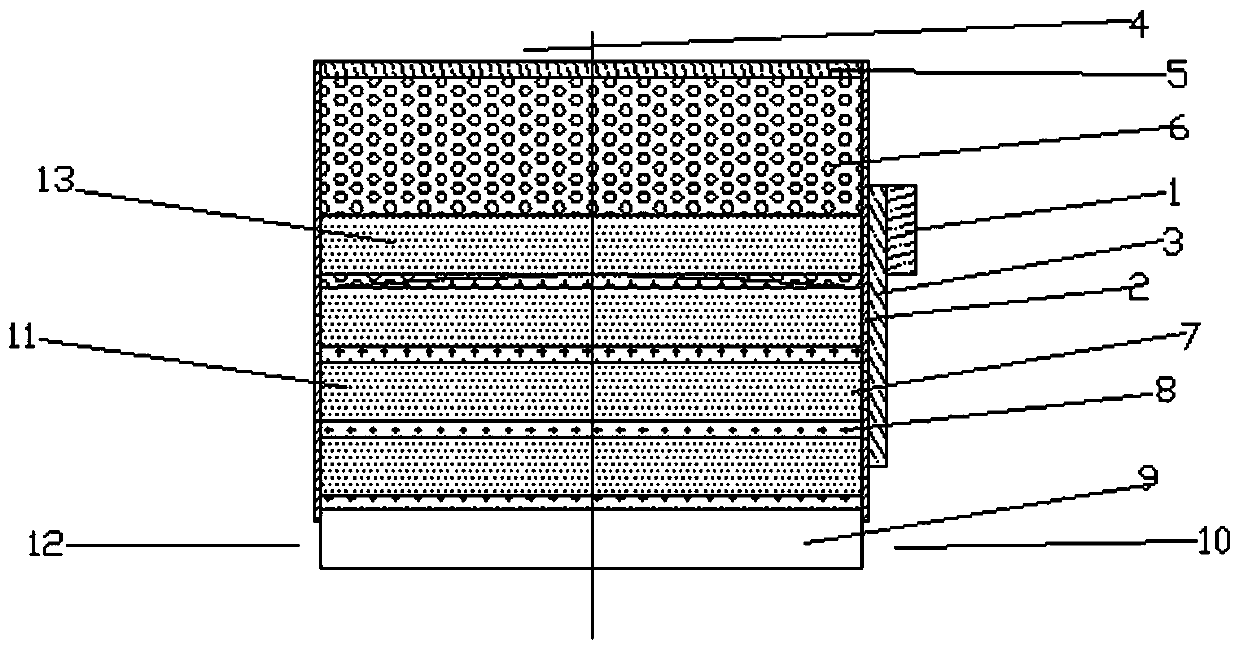

[0014] An aluminum frame anode that changes the anode current circuit includes an aluminum frame 2 and several conductors 13 arranged in the aluminum frame 2, and is only connected to the anode bus 1 on one side of the aluminum frame anode in the vertical direction.

[0015] An anode guide rod 3 is also arranged between the anode bus bar 1 and the aluminum frame 2 .

[0016] The number of the anode bus bars 1 is at least two groups.

[0017] A set of anode busbars 1 is simultaneously connected to one side in the vertical direction of several aluminum frame anodes.

[0018] Such as figure 1 As mentioned above, the anode busbar 1 is installed on the aluminum frame anode A side of the longitudinal center line 4 of the aluminum frame anode. Easy and voltage reduction requirement determination. Through a number of anode guide rods 3 arranged between the anode bus bar 1 and the aluminum frame 2, the current on the anode bus bar 3 is introduced to the power supply side (A side) of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com