Carding machine with coiler

A technology of coiler and carding machine, applied in winding mechanism, coiling mechanism, deburring device, etc., can solve the problems of wire loss, broken ends, removal of short lint, unclean dust and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

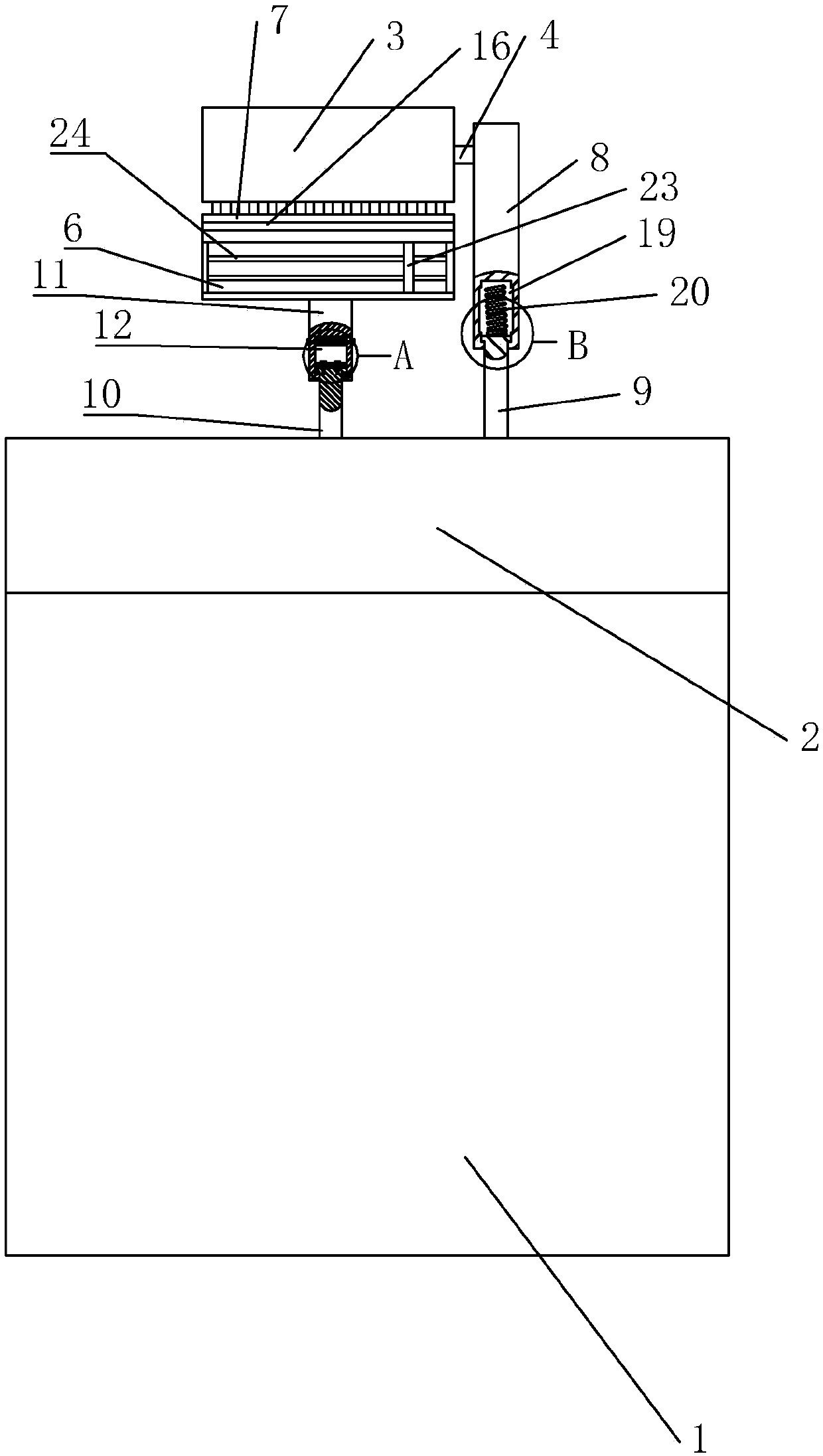

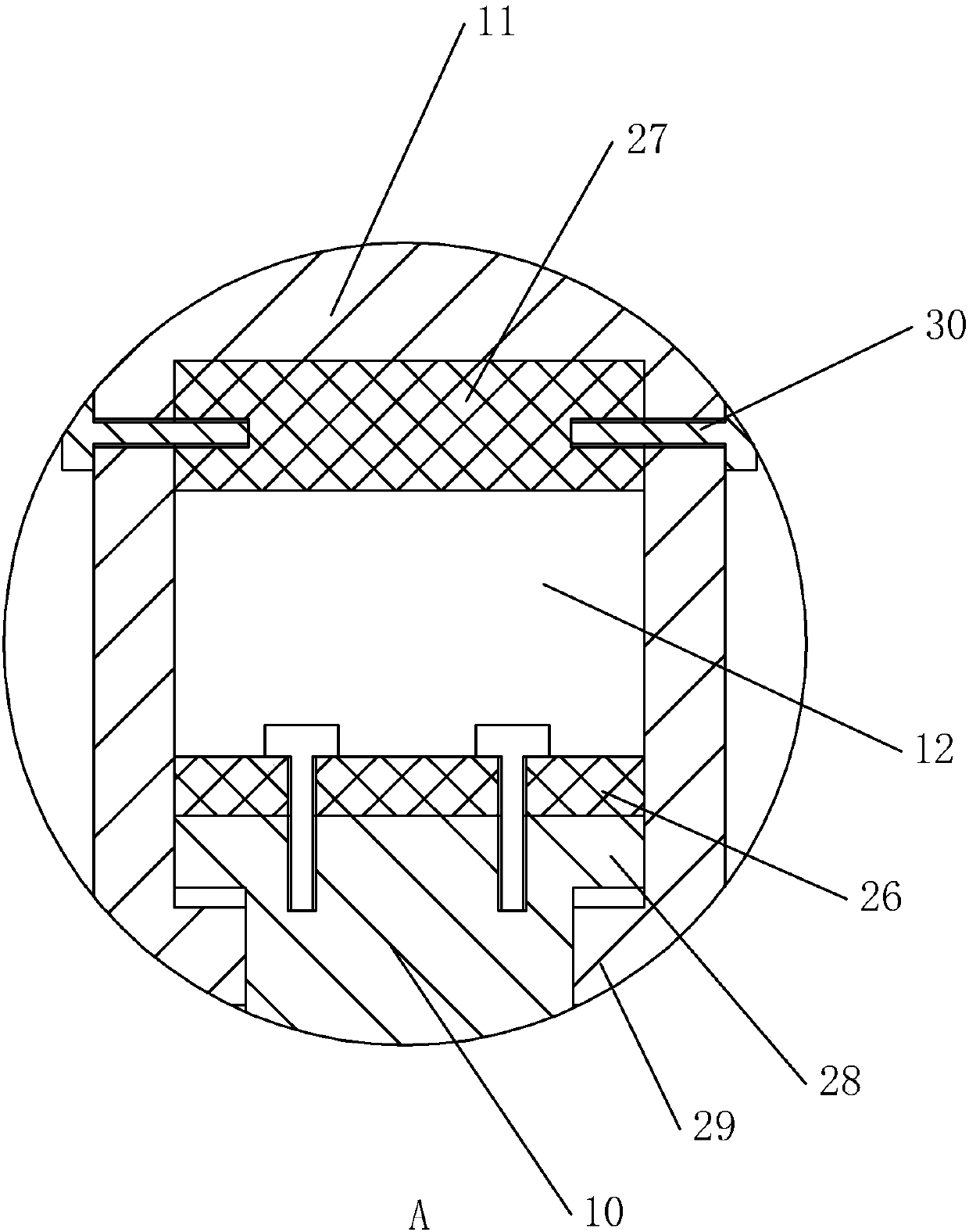

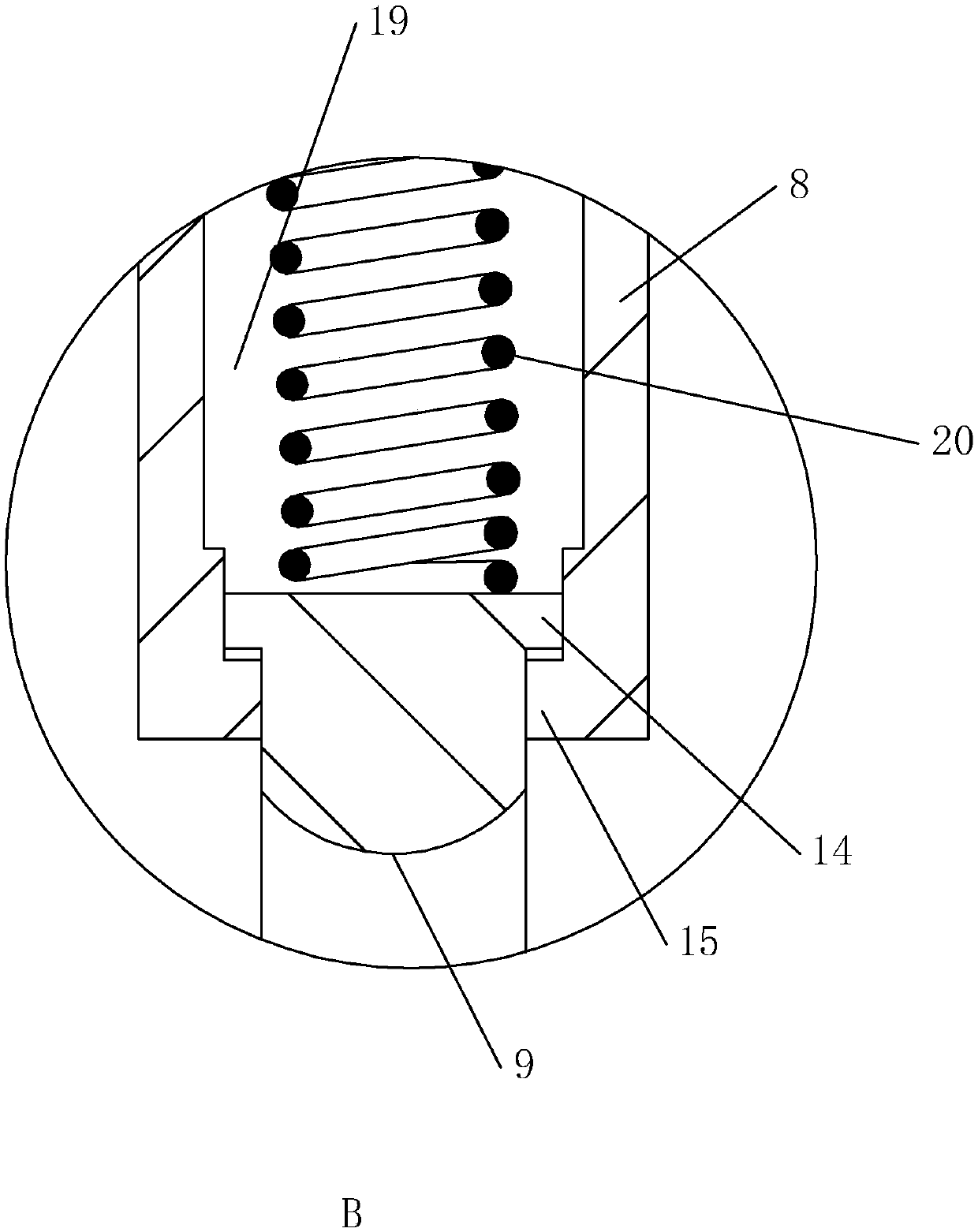

[0028] refer to Figure 1 to Figure 3 As shown, a carding machine with a coiler implemented in this case includes a coiler, and the coiler includes a barrel body 1 and a halter cover 2 installed on the barrel body 1, and the halter cover Shell 2 is provided with support frame and cylinder 3, and described cylinder 3 is installed on the halter cover shell 2 by support frame, and described support frame is set as first support frame 8 and second support frame 9, and described cylinder 3 and second The support frame 9 is connected, one end of the first support frame 8 is connected with the halter cover 2, and the other end is connected with the second support frame 9, and the first support frame 8 is provided with a mounting groove for placing the second support frame 9 19. An elastic member 20 is installed in the installation groove 19, and the two ends of the elastic member are respectively connected with the first support frame 8 and the second support frame 9, and the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com