Fabricated cave dwelling and building method

A prefabricated, kiln cave technology, which is applied in construction, building structure, shaft equipment, etc., can solve the problems of high production cost, lack of shock resistance, poor maintenance of the kiln roof, etc., and achieve the effect of stable quality and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

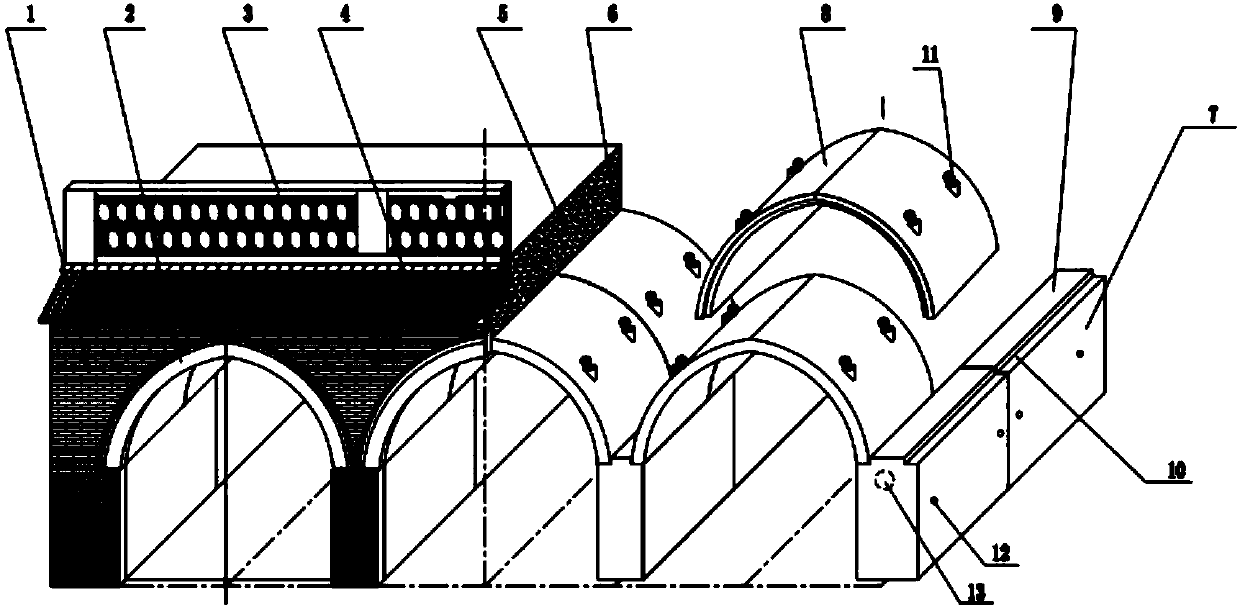

[0024] Such as figure 1 As shown, a prefabricated cave dwelling includes a front wall 1, a kiln entrance 2, a weir wall 3, and roof tiles with eaves and rain pads 4. The front face of the building structure, the flower weir wall 3 and the slope tile eaves 4 are all arranged on the top of the front wall of the cave frame building structure, which also includes the kiln leg part 7 and the kiln arch part 8. The kiln leg part Piece 7 is made of reinforced concrete integrally. There is a convex platform 9 in the middle of the top of the kiln leg part 7, and concave platforms 10 are provided on both sides. The other end surface of the kiln leg part 7 is provided with a male stop of the convex platform, and a plurality of kiln leg parts 7 are longitudinally assembled through the male stop of the convex platform and the female stop of the concave platform to form the kiln leg of the kiln dwelling. A plurality of kiln leg parts 7 are horizontally arranged to form a plurality of row ki...

Embodiment 2

[0027] Such as figure 1 Shown, a kind of construction method of prefabricated cave dwelling, comprises the following steps:

[0028] (1), according to the design depth of the cave dwelling, the kiln legs of the cave dwelling are formed by longitudinally assembling the plurality of kiln leg parts 7 through the male stop of the convex platform and the female stop of the concave platform;

[0029] (2), according to the design width of the cave dwelling, a plurality of kiln leg parts 7 are horizontally arranged to form the kiln legs of the row cave dwellings of a plurality of specifications;

[0030] (3) According to the depth of the kiln legs, a plurality of kiln arch parts 8 are longitudinally assembled through the male stop of the convex platform and the female stop of the concave platform to form the kiln arch of the cave dwelling,

[0031] (4) According to the distance between adjacent kiln legs and the two ends of the kiln arch parts 8 of corresponding specifications, they ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com