Heat-insulating solar power generation automobile skylight and preparation process thereof

A car sunroof and preparation technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of not being able to enjoy the fun of the sunroof, the sunroof cannot be effectively insulated, and the temperature inside the car is overheated in summer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

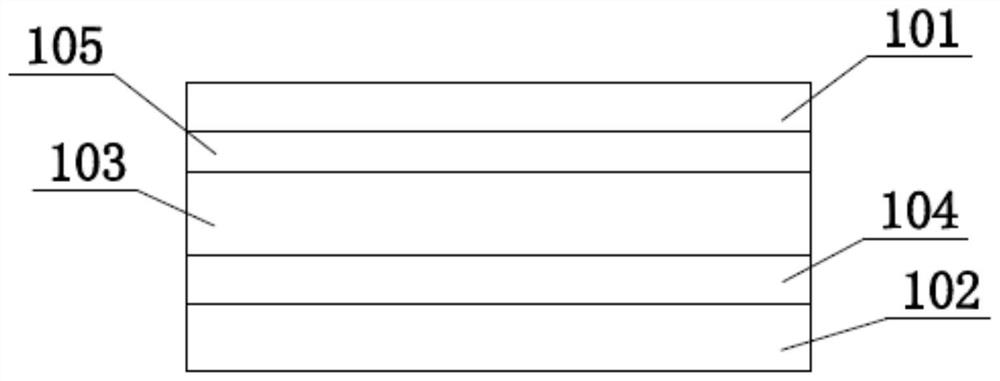

[0046] like figure 1 As shown, a sunroof for heat-insulating solar power generation vehicles includes a light-transmitting surface layer 101 made of tempered glass, a base layer 102 made of PMMA, and a battery chip layer 103 arranged between the tempered glass and PMMA. The battery chip layer 103 is formed by connecting several CIGS flexible chips in series.

[0047] In addition, a foam layer for heat insulation is also provided between the battery chip layer 103 and the PMMA. In this solution, the foam layer is made of a mixture of acrylate and polyester, and the thickness of this layer is 80 μm. Ensure that the sunroof has excellent heat insulation effect, and form a protective film on the roof sunroof to ensure that the interior of the car is warm in winter and cool in summer. At the same time, the foam layer also has a certain damping effect on the skylight. Once the skylight is subjected to external force, it can absorb the energy impact of the external force on the in...

Embodiment 2

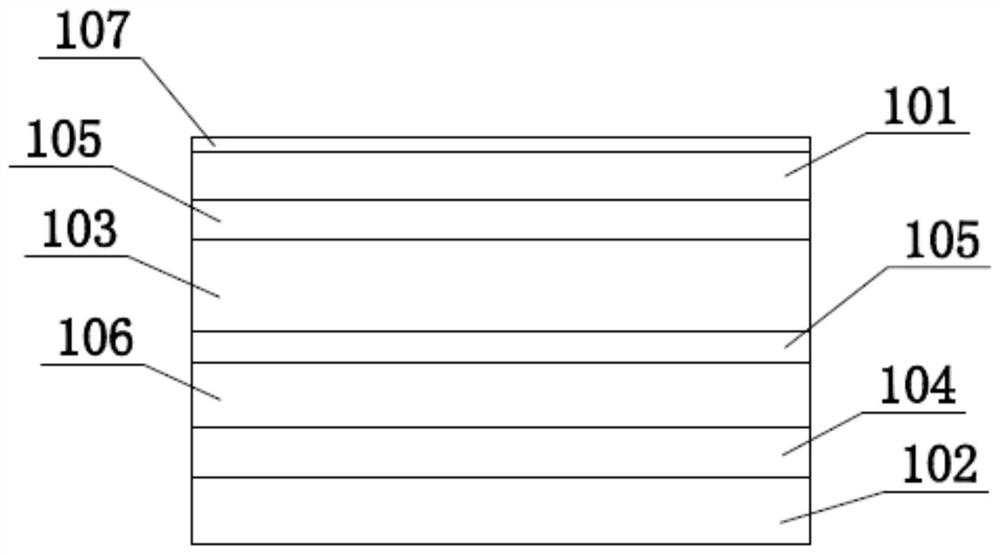

[0051] combine figure 2 As shown, the difference from Embodiment 1 is that a water vapor barrier layer 106 is provided between the battery chip layer 103 and the foam layer. The water vapor barrier layer 106 has a thickness of 0.6 μm, is made of silicon oxide, and has a water vapor transmission rate of 10. -6 g / m 2 Day. The setting of the water vapor barrier layer 106 effectively ensures the waterproof requirement of the battery chip layer 103 and ensures the safety of the solar sunroof.

[0052] An adhesive layer 105 is filled between the battery chip layer 103 and the water vapor barrier layer 106 to bond and fix the battery chip layer 103 and the water vapor barrier layer 106 . At the same time, it can also play an energy-absorbing and buffering role when the sunroof is subjected to external force, reducing the risk of damage to the internal components of the sunroof, especially the battery chip layer 103 due to external force. The adhesive layer 105 is a polyurethane ...

Embodiment 3

[0057] A preparation process for preparing the above-mentioned thermal insulation solar power generation car sunroof includes:

[0058] Preparation of the water vapor barrier layer: select the first piece of PMMA, wash and dry it, and prepare the water vapor barrier layer 106 on one surface by atomic layer deposition.

[0059] Prepare the adhesive layer: clean the tempered glass and dry it. The tempered glass, the battery chip layer 103 and the above-mentioned water vapor barrier layer 106 are stacked sequentially from top to bottom and fixed with a clamp, wherein the water vapor barrier layer 106 faces the side of the battery chip layer 103 .

[0060] Mix diphenylmethane diisocyanate, the main material of polyurethane glue, and the corresponding curing agent at a speed of 2000 rpm to mix evenly. The barrier layers 106 are poured and bonded respectively, and the adhesive layer 105 is obtained after cooling and forming at room temperature.

[0061] Preparation of foaming adhe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com