Jade mud and titanium dioxide mixed coating and preparation method thereof

A technology of titanium dioxide and mixed coatings, applied in antifouling/underwater coatings, coatings, construction, etc., can solve the problem of high formaldehyde purification efficiency, achieve good decorative effects, natural and soft light, and less visual fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

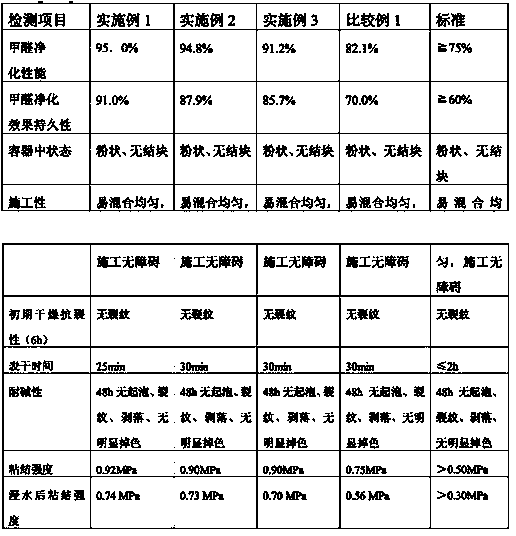

Examples

Embodiment l

[0033] Jade mud and titanium dioxide mixed coating formula 1 of the present invention:

[0034] Choose natural jade powder from Xiuyan 850kg

[0035] Titanium dioxide powder 10 kg

[0036] Negative oxygen ion powder 100kg

[0037] Dispersible rubber powder 50kg

[0038] Hydroxyethyl methylcellulose 5kg

[0039] The preparation method of described jade mud coating is as follows:

[0040] Step 1. Strictly screen the natural jade and titanium dioxide powder produced in Xiuyan and crush them into small pieces by the ore crusher. Example

[0041] If the diameter is less than 10cm, then grind it into 800 mesh powder with a Raymond mill;

[0042] Step 2, the titanium dioxide powder is ground into 100 mesh granules;

[0043] Step 3: Mix and stir 800kg of natural jade powder and 100kg of titanium dioxide powder, and stir with a dry powder mixer

[0044] Mix for 30 minutes; then add 150kg of negative oxygen ion powder, 100kg of dispersible rubber powder and 10kg of hydroxyethyl m...

Embodiment 2

[0047] Jade mud and titanium dioxide mixed coating formula 2 of the present invention:

[0048] Xiuyan Natural Jade Powder 800kg

[0049] Titanium dioxide powder l00kg

[0050] Negative oxygen ion powder 150kg

[0051] Imported dispersible rubber powder 100kg

[0052] Hydroxyethyl methylcellulose 1 kg

[0053] The preparation method of described jade mud and titanium dioxide mixed coating is as follows:

[0054] Step 1. Strictly screen the natural jade and titanium dioxide powder produced in Xiuyan and crush them into small pieces by an ore crusher

[0055] If the diameter is less than 10cm, grind it into 800-mesh powder with a Raymond mill;

[0056] Step 2. Grinding the negative oxygen ion powder into 400 mesh particles;

[0057] Step 3, mix and stir 800kg of natural jade powder and 100kg of titanium dioxide powder particles, and use a dry powder mixer

[0058] Stir for 25 minutes; then add 150kg of negative oxygen ion powder, 100kg of dispersible rubber powder, and 1k...

Embodiment 3

[0060] The formula 3 of jade mud and titanium dioxide mixed coating of the present invention:

[0061]In order to make the paint have different colors, different natural color powders can be added.

[0062] Xiuyan Natural Jade Powder 820kg

[0063] Titanium dioxide powder 8 kg

[0064] Negative oxygen ion powder 12kg

[0065] Dispersible rubber powder 7kg

[0066] Hydroxyethyl methylcellulose 0.8kg

[0067] Natural Toner 2.0kg

[0068] The preparation method of described jade mud and titanium dioxide mixed coating is as follows:

[0069] Step 1, the natural jade and titanium dioxide produced in Xiuyan are strictly screened and crushed into small pieces by an ore crusher, for example, the diameter is less than 10cm, and then ground into 800-mesh powder with a Raymond mill;

[0070] Step 2. Grinding the negative oxygen ion powder into 400 mesh particles;

[0071] Step 3: Mix and stir 800kg of natural jade powder and 100kg of titanium dioxide powder particles, and stir wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com