Method for preparing denitration catalytic composition and flue gas denitration method

A composition and denitrification technology, applied in the field of flue gas purification, can solve the problems of denitrification wastewater generation, unstable denitrification efficiency, and high energy consumption in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

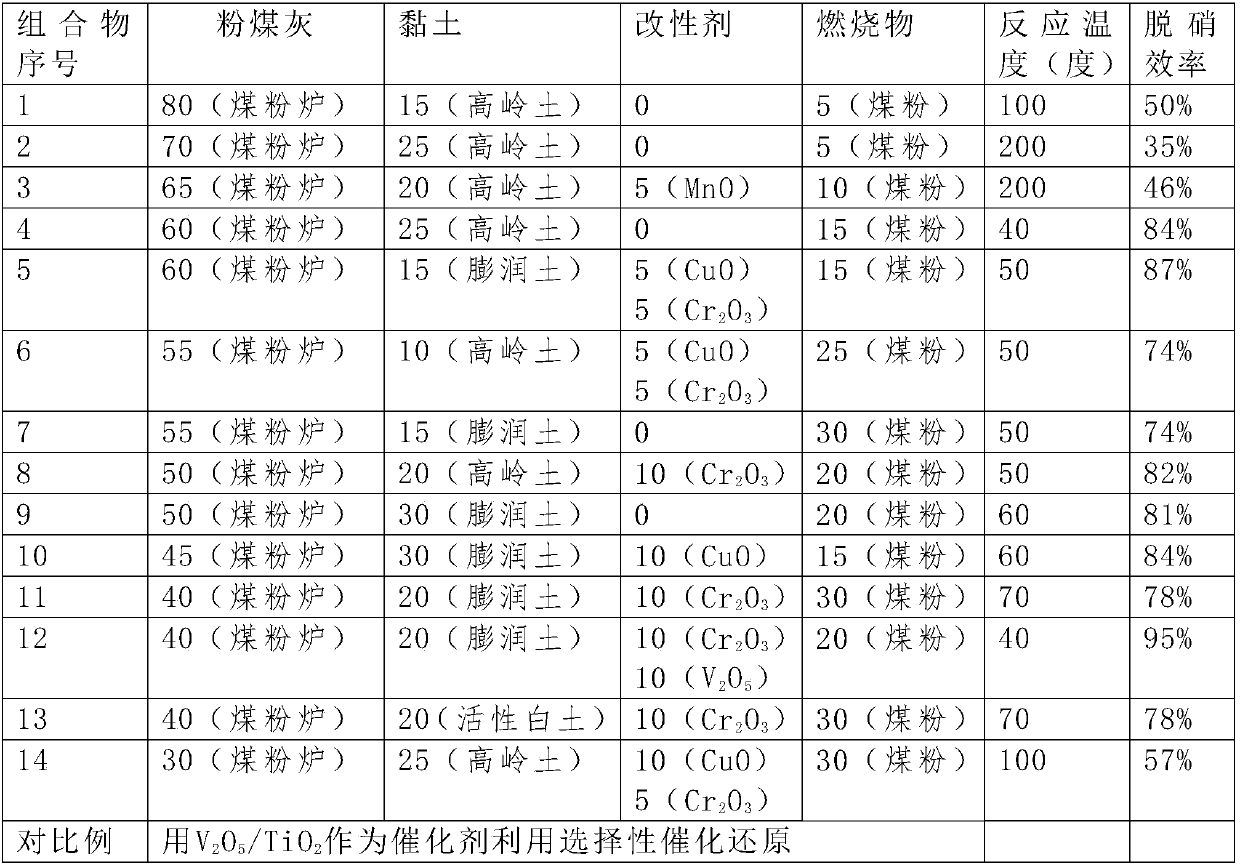

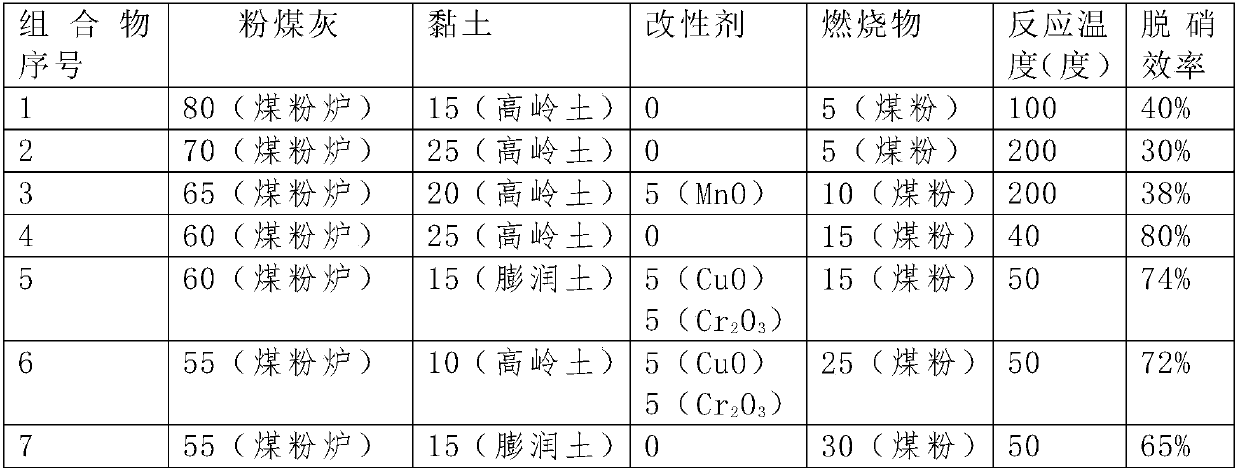

[0030] Specific embodiments provided by the present invention are described below.

[0031] The embodiment of the present invention provides a method for preparing a denitration catalytic composition, comprising the following steps:

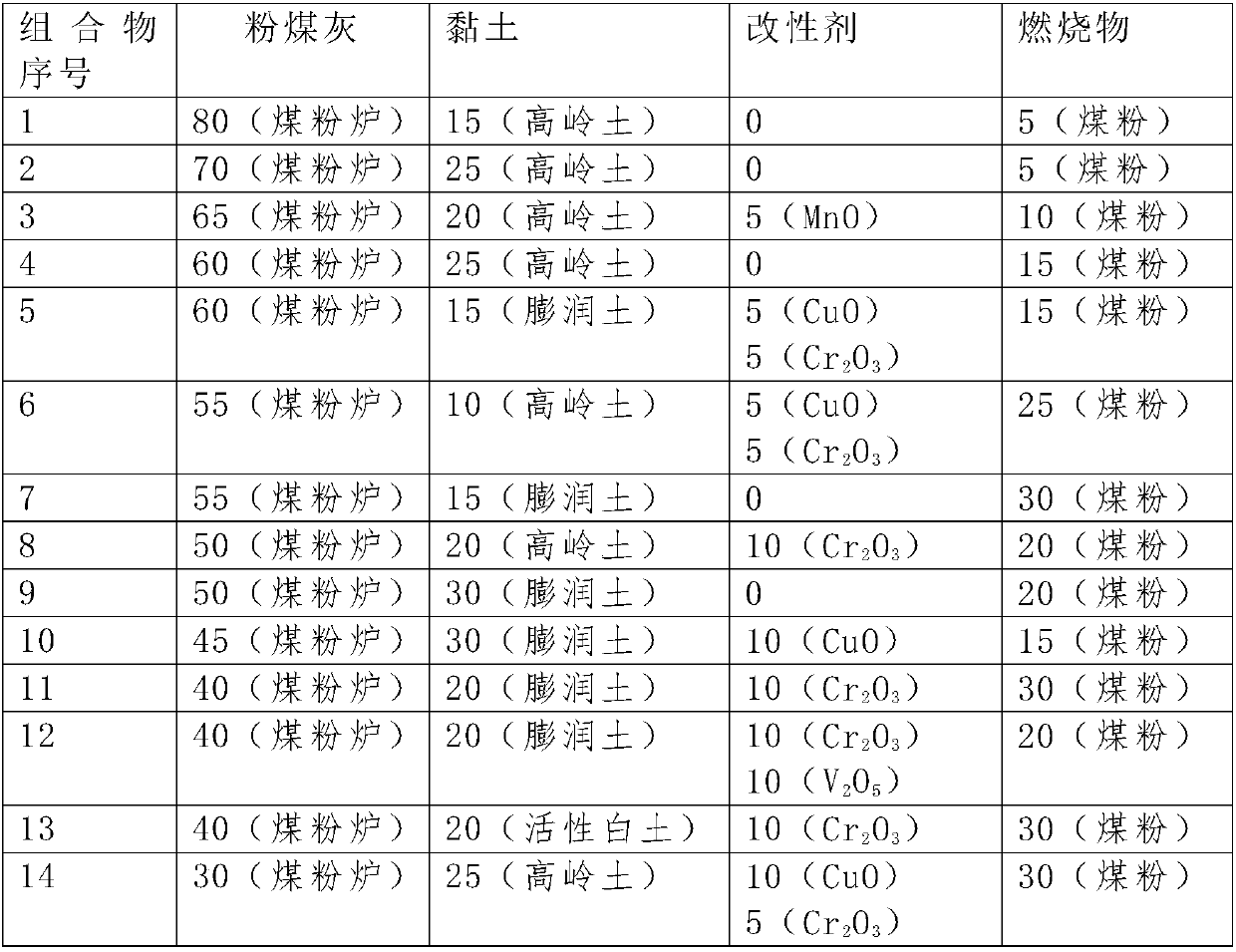

[0032] S100, ingredients. By weight, the weight (grams) and specific types of coal ash, clay, modifiers and combustibles are used for batching.

[0033] Wherein, the clay may be at least one of kaolin, bentonite and attapulgite. Combustion products can be at least one of coal powder and coke powder; modifiers can be MnO, V 2 o 5 、Cr 2 o 3 , CuO, Fe 2 o 3 、Al 2 o 3 、TiO 2 At least one of carbon and carbon; the fly ash can be the fly ash produced by a pulverized coal furnace.

[0034] Concrete batching and weight ratio are as follows:

[0035]

[0036] S200, mixing the powder materials with water and stirring evenly, extruding to form granules.

[0037] After the batching is completed, mix the powder materials and add an appropriate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap