Molybdenum carbide catalyst for producing nerol and geraniol by citral hydrogenation

A catalyst, nerol technology, applied in physical/chemical process catalysts, tungsten/molybdenum carbides, carbides, etc., can solve the problem of high cost of noble metal hydrogenation catalysts, achieve low cost, high product quality, and expanded applications range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] 1. Catalyst preparation

[0066] Take molybdenum atomic concentration as 0.07mol / L (NH 4 ) 6 Mo 7 o 24 4H 2 0.15 L of O aqueous solution, 0.18 mol of aniline was added to the solution, and 2 mol / L of HCl solution was added dropwise under stirring until pH=2.0 to obtain material I;

[0067] Put material I at 60°C for 12 hours to obtain material II, filter, wash the filter cake with water three times with 200 mL of water each time, then wash the filter cake with absolute ethanol three times with 100 mL of ethanol each time, and finally dry the filter cake in vacuum at 60°C After 12 hours, material III was obtained.

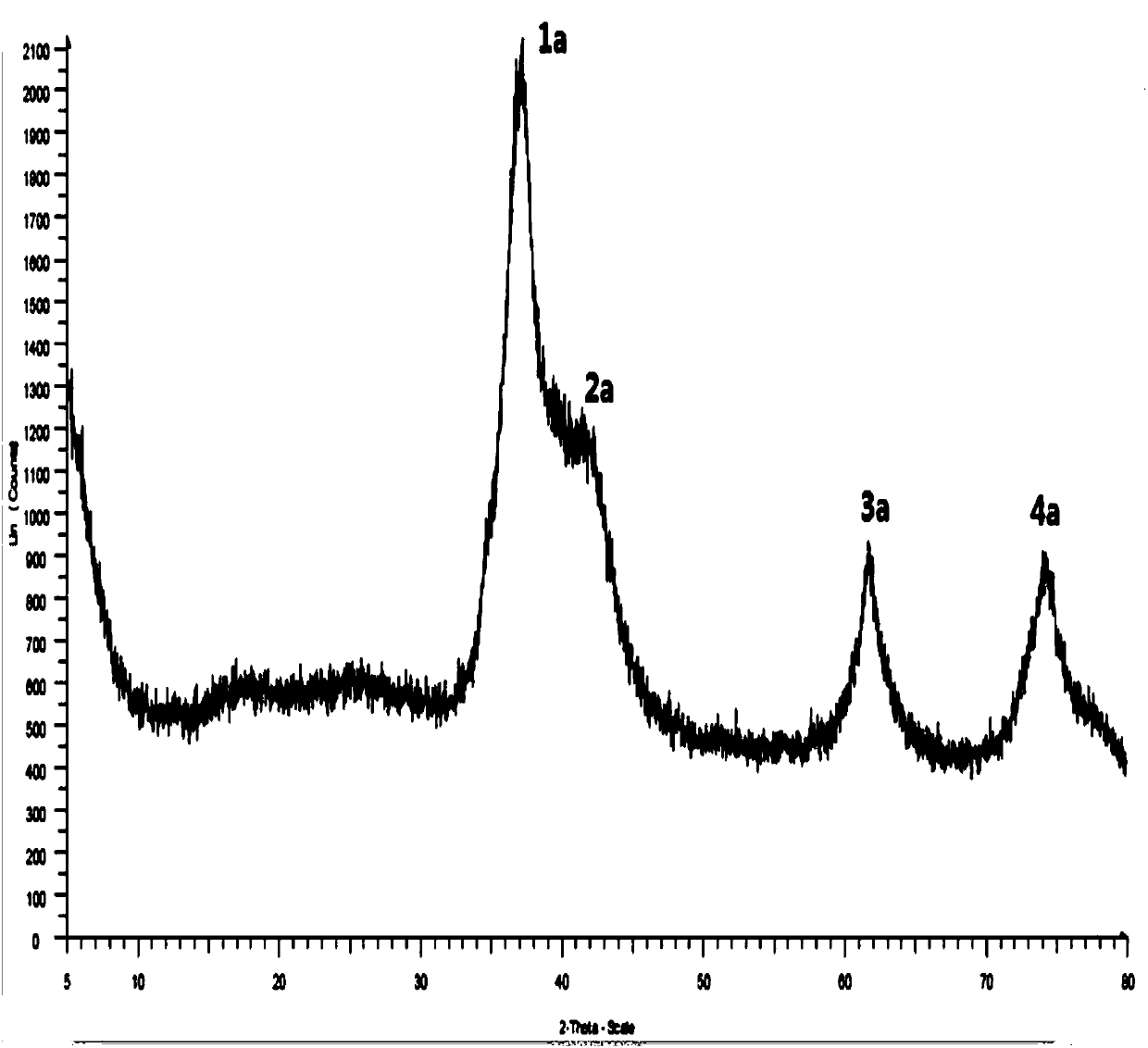

[0068] Material III is pre-calcined and roasted under a nitrogen atmosphere: the temperature is raised from 20°C to 300°C at a rate of 5°C / min, and then raised from 300°C to 700°C at a rate of 1°C / min, and kept at 700°C 2 hours. After cooling down to room temperature and cooling for 48 hours under nitrogen protection, the desired molybdenum carbide cat...

Embodiment 2

[0078] 1. Catalyst preparation

[0079] Take molybdenum atomic concentration as 0.07mol / L (NH 4 ) 6 Mo 7 o 24 4H 2 0.15 L of O aqueous solution, 0.18 mol of 1,6-hexanediamine was added to the solution, and 2 mol / L of HCl solution was added dropwise under stirring until pH = 2.0 to obtain material I;

[0080] Put material I at 60°C for 12 hours to obtain material II, filter, wash the filter cake with water three times with 200 mL of water each time, then wash the filter cake with absolute ethanol three times with 100 mL of ethanol each time, and finally dry the filter cake in vacuum at 60°C After 12 hours, material III was obtained.

[0081] Suspend 3.39g of material III in 100mL of water, add 1.45g of APS, drop in 2mol / L HCl solution to pH=2.5 under stirring, filter, wash the filter cake with water three times with 200mL of water each time, and finally dry the filter cake in vacuum at 60°C 12 hours, got material IIIB

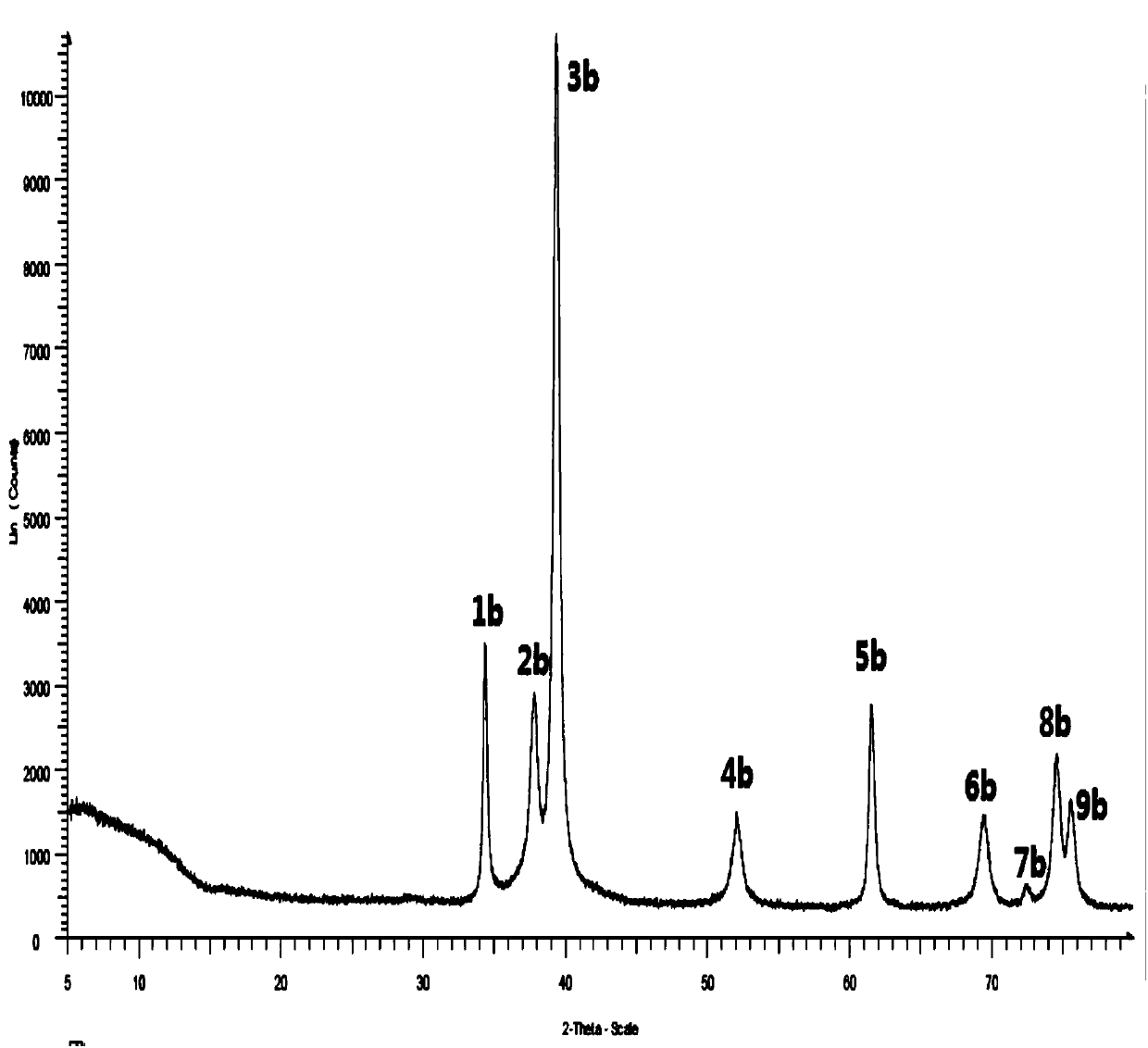

[0082] Material IIIB is pre-calcined and roasted in a...

Embodiment 3

[0090] 1. Catalyst preparation

[0091] Take molybdenum atomic concentration as 0.07mol / L (NH 4 ) 6 Mo 7 o 24 4H 2 O aqueous solution was 0.15 L, and 0.18 mol of tetraethylenepentamine was added to the solution, and 2 mol / L of HCl solution was added dropwise under stirring until pH=2.0 to obtain material I.

[0092] Put material I at 60°C for 12 hours to obtain material II, filter, wash the filter cake with water three times with 200 mL of water each time, then wash the filter cake with absolute ethanol three times with 100 mL of ethanol each time, and finally dry the filter cake in vacuum at 60°C After 12 hours, material III was obtained.

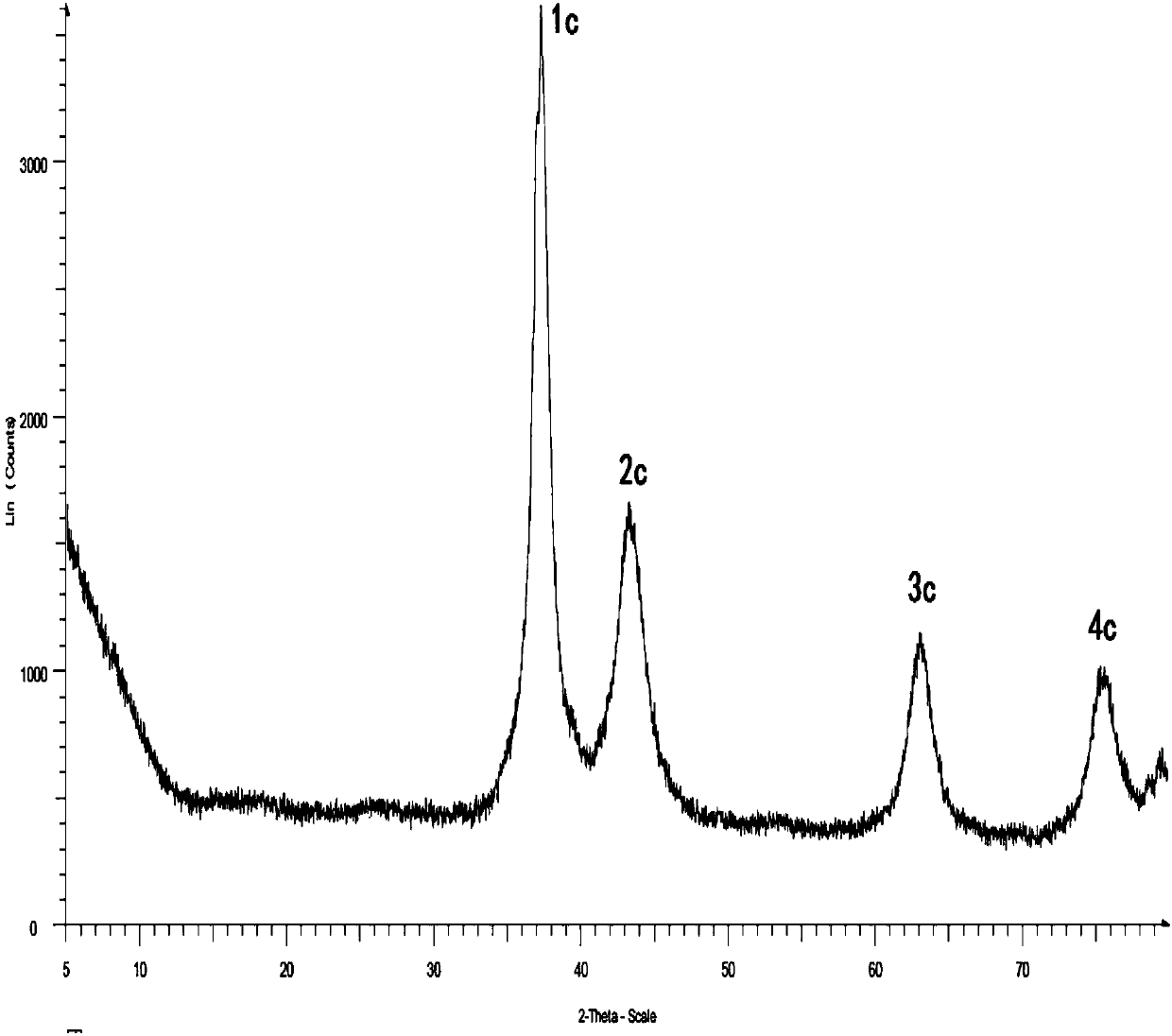

[0093] Material III is pre-calcined and roasted under a nitrogen atmosphere: the temperature is raised from 20°C to 300°C at a rate of 5°C / min, and then raised from 300°C to 700°C at a rate of 1°C / min, and kept at 700°C 2 hours. After cooling down to room temperature and cooling for 48 hours under the protection of nitrogen, the des...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap