Grinding mat, grinding device and grinding mat manufacturing method

A technology for grinding pads and grinding layers, which is applied in grinding devices, grinding machine tools, grinding tools, etc., and can solve problems such as scratches on substrates to be ground, difficulties in circulation of grinding fluid, and clogging of polishing powders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

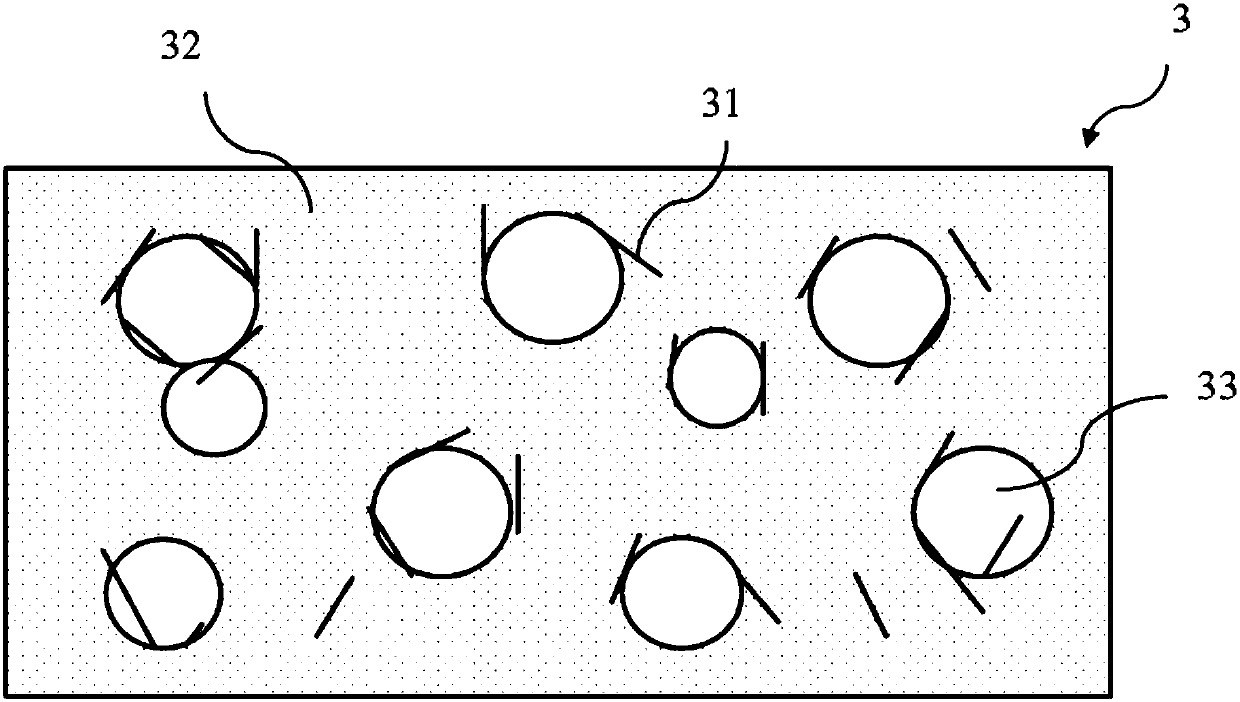

[0050] The invention provides a grinding pad comprising:

[0051] grinding layer, the grinding layer contains

[0052] polymeric elastic body; and

[0053] A plurality of titanium dioxide nanowires are independent from each other and uniformly and randomly dispersed in the polymer elastic body.

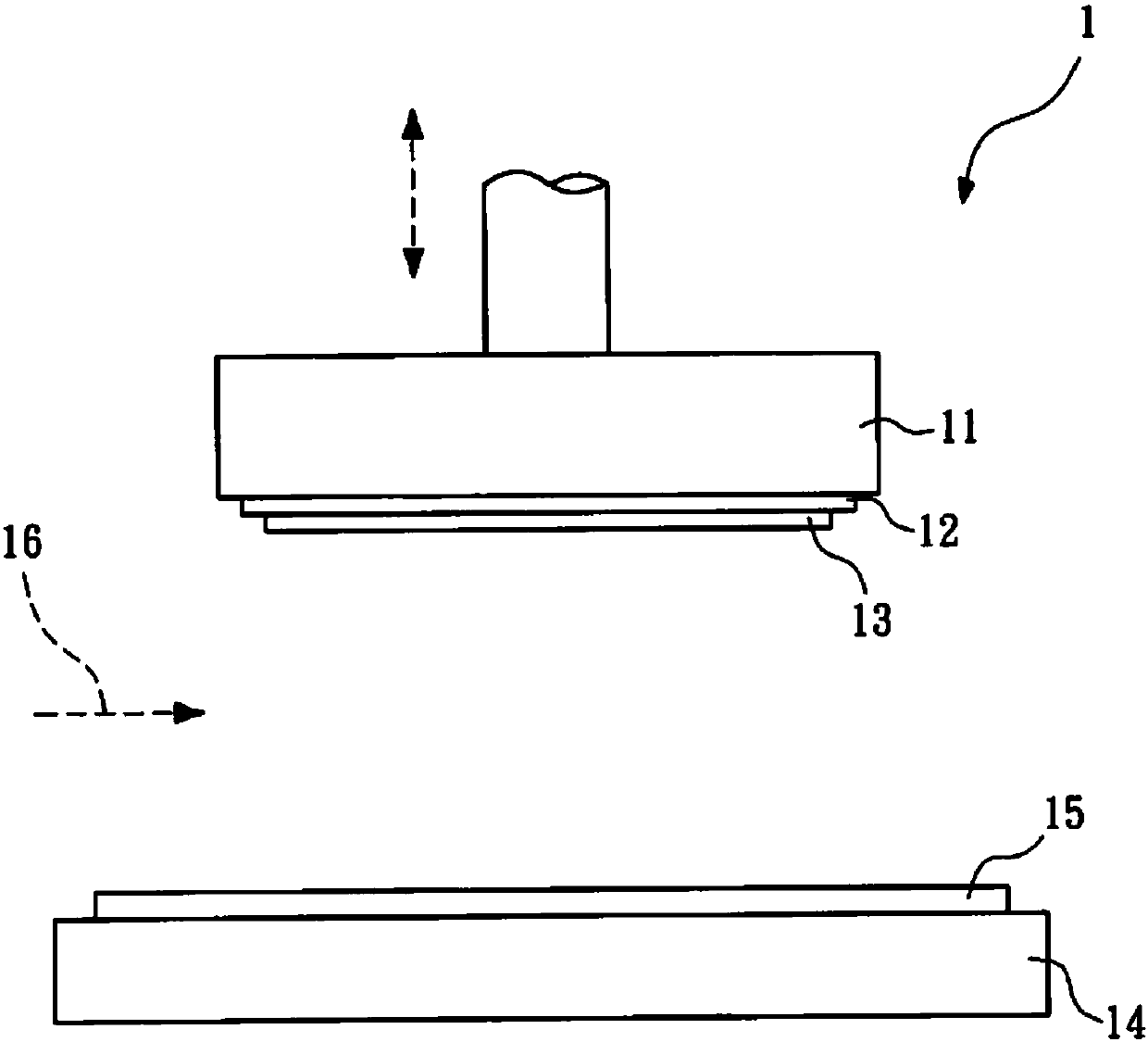

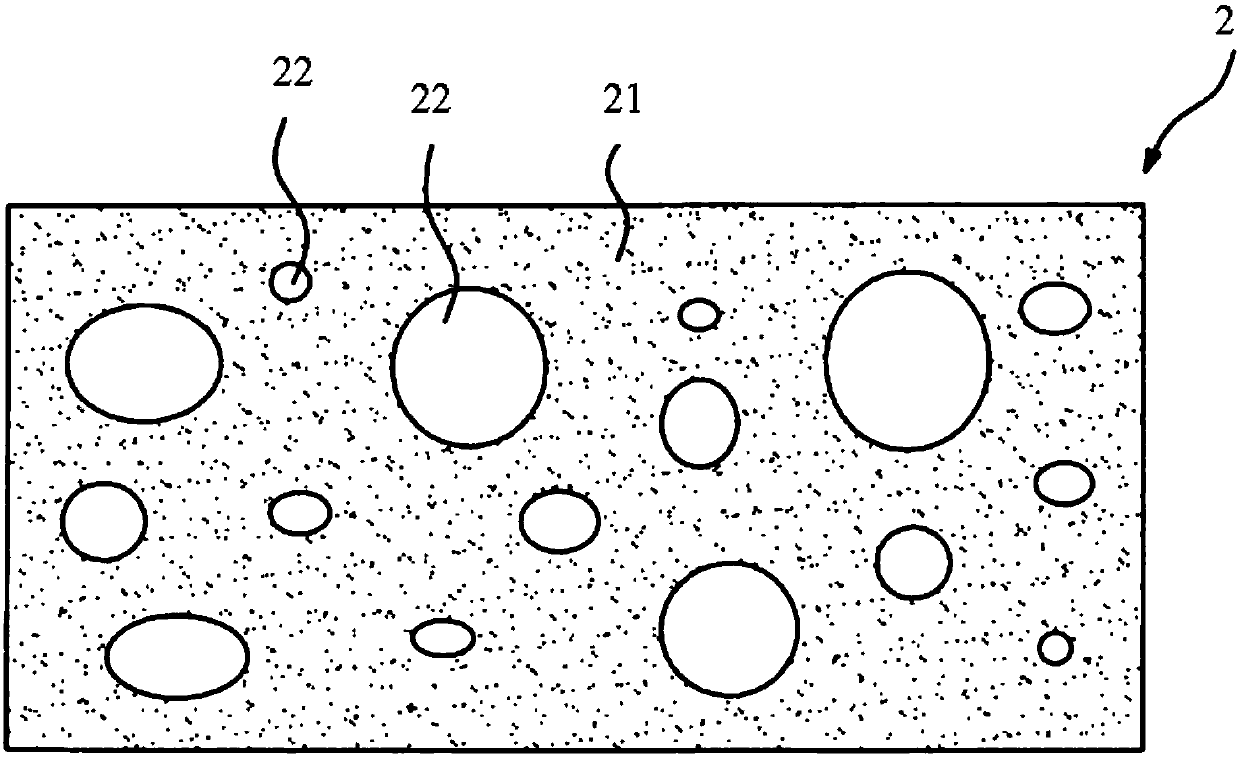

[0054] "Polishing pad" according to the present invention refers to a pad used to bear against a substrate to be polished in a chemical mechanical polishing process. The slurry is used to make the rough surface of the substrate to be ground be ground to a smooth surface. The "polishing layer" according to the present invention refers to a component used in a polishing pad to contact and rub the substrate to be polished, that is, a component in the polishing pad that cooperates with a polishing slurry to actually perform polishing. The abrasive layer can be in a sheet structure, or form a sheet structure together with other components. see image 3 According to the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com