Capacitive pressure touch sensor and electronic component

A touch sensor, capacitive technology, used in instruments, electrical digital data processing, non-polymer adhesive additives, etc., can solve problems such as poor user experience, limited sensor application, and low sensor sensitivity. The effect of increased touch sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

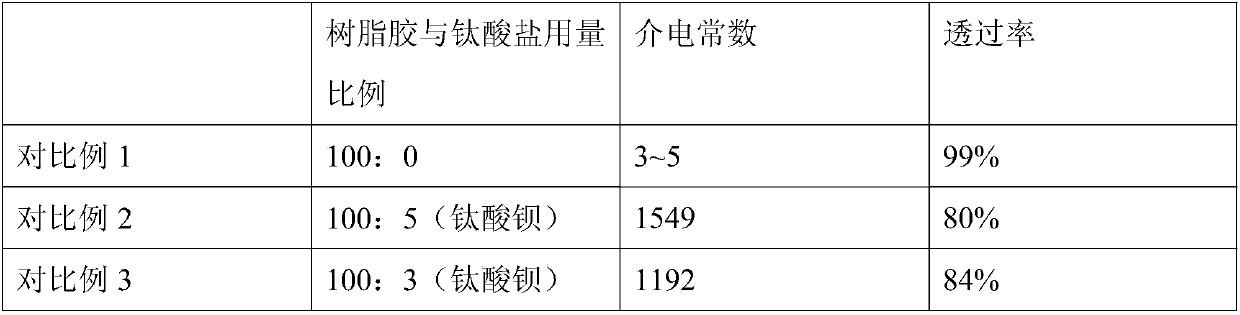

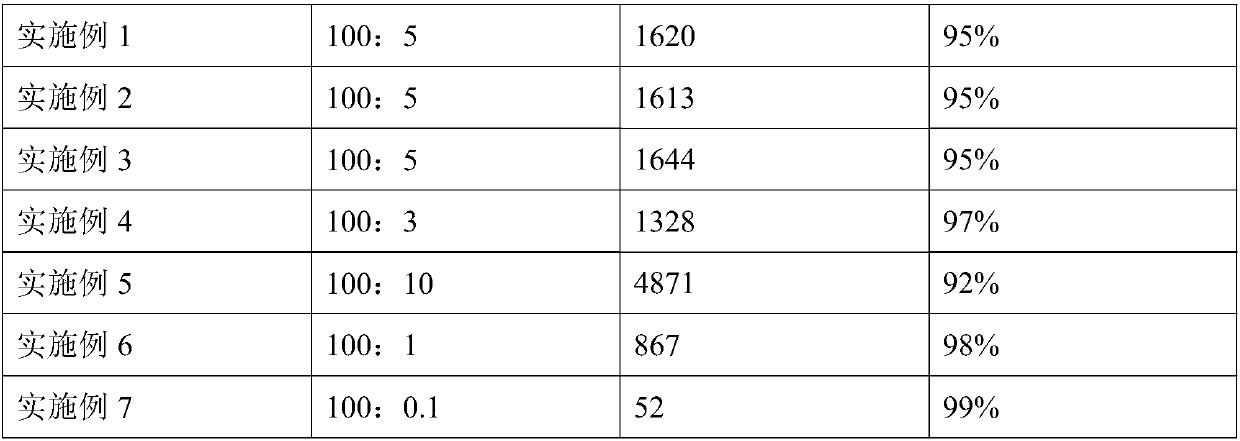

Examples

Embodiment 1

[0041] This embodiment provides an adhesive and a preparation method thereof.

[0042] 1): Weigh 100g of acrylic resin, 5g of nano-scale CCTO powder, and 0.5g of thermal curing agent, and mix them together with 40khz ultrasonic + magnetic stirring for 5 hours, so that CCTO and thermal curing agent are evenly dispersed in the colloid;

[0043] 2): Filter through a 1800-mesh stainless steel screen;

[0044] 3): Put the filtered glue into the vacuum cavity, vacuumize to 0.01torr, and keep it for 2 hours;

[0045] 4): Packaging glue.

Embodiment 2

[0047] This embodiment provides an adhesive and a preparation method thereof.

[0048] 1): Weigh 100g of epoxy resin, 5g of nano-scale CCTO powder, and 0.5g of thermal curing agent, mix them together with 40khz ultrasonic + magnetic stirring for 5 hours, so that CCTO and thermal curing agent are evenly dispersed in the colloid;

[0049] 2): Filter through a 1800-mesh stainless steel screen;

[0050] 3): Put the filtered glue into the vacuum cavity, vacuumize to 0.01torr, and keep it for 2 hours;

[0051] 4): Packaging glue.

Embodiment 3

[0053] 1): Weigh 100g of silicone resin, 5g of nano-scale CCTO powder, and 0.5g of thermal curing agent, and mix them together with 40khz ultrasonic + magnetic stirring for 5 hours, so that CCTO and thermal curing agent are evenly dispersed in the colloid;

[0054] 2): Filter through a 1800-mesh stainless steel screen;

[0055] 3): Put the filtered glue into the vacuum cavity, vacuumize to 0.01torr, and keep it for 2 hours;

[0056] 4): Packaging glue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com