Small ditching and fertilization integrated machine for tea trees

An all-in-one, small technology, applied in fertilization devices, excavation/covering of trenches, planting methods, etc., can solve the problems of low efficiency, high labor intensity, unfavorable large-scale planting of tea trees, etc., to achieve convenient and safe use and reduce labor. Strength, compact design and clever effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

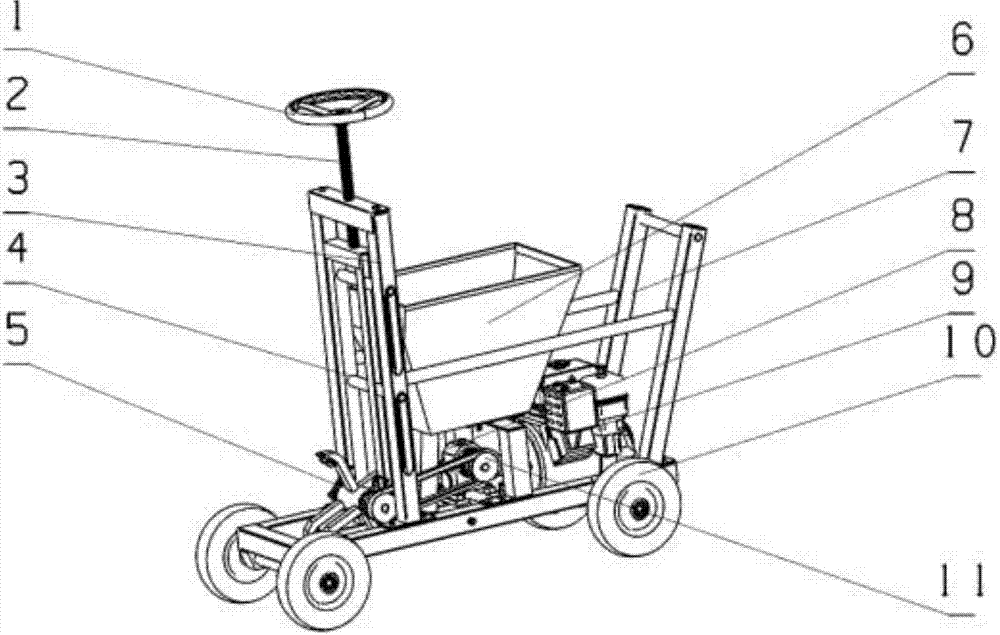

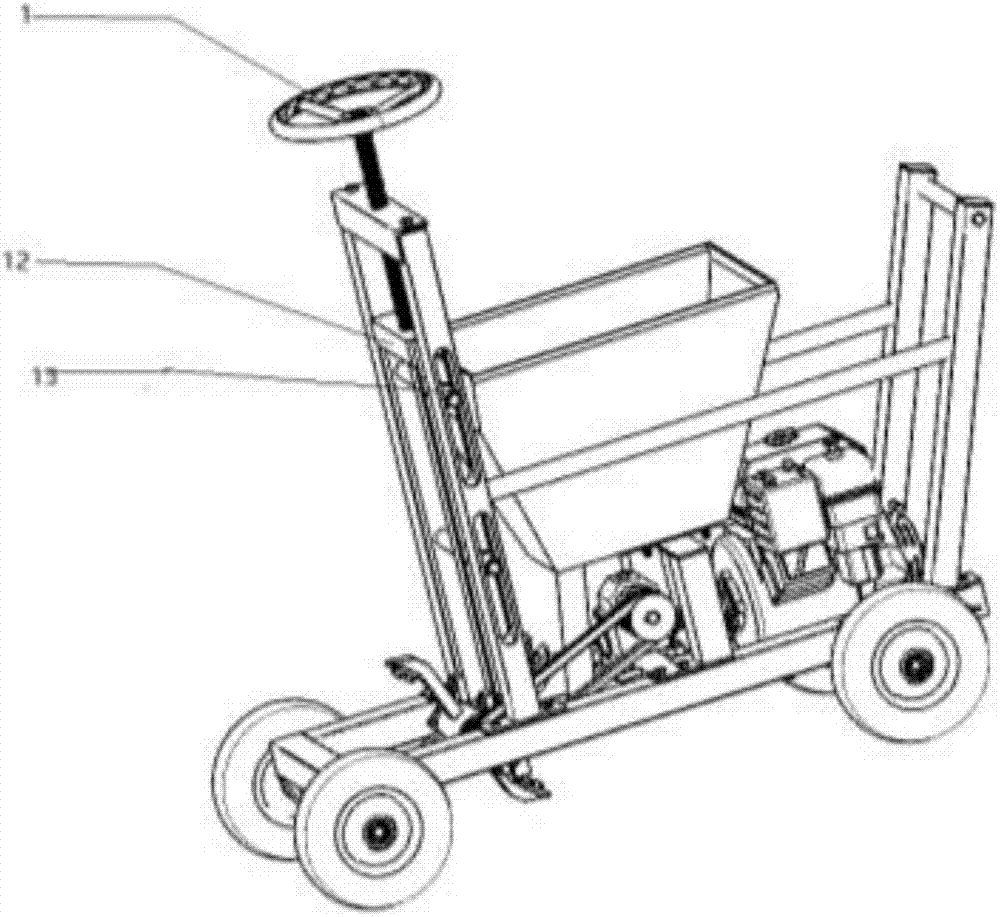

[0035] Such as Figure 1 to Figure 10 As shown, the small tea tree ditching and fertilizing integrated machine described in the present invention is a small tea tree ditching and fertilizing integrated machine, comprising a mechanism chassis, a cutter screw lifting mechanism, a cutter digging mechanism, a small diesel engine 9 and a speed reducer 8, The fertilization and blanking mechanism and the walking thrust mechanism, the specific mechanism and connection relationship are:

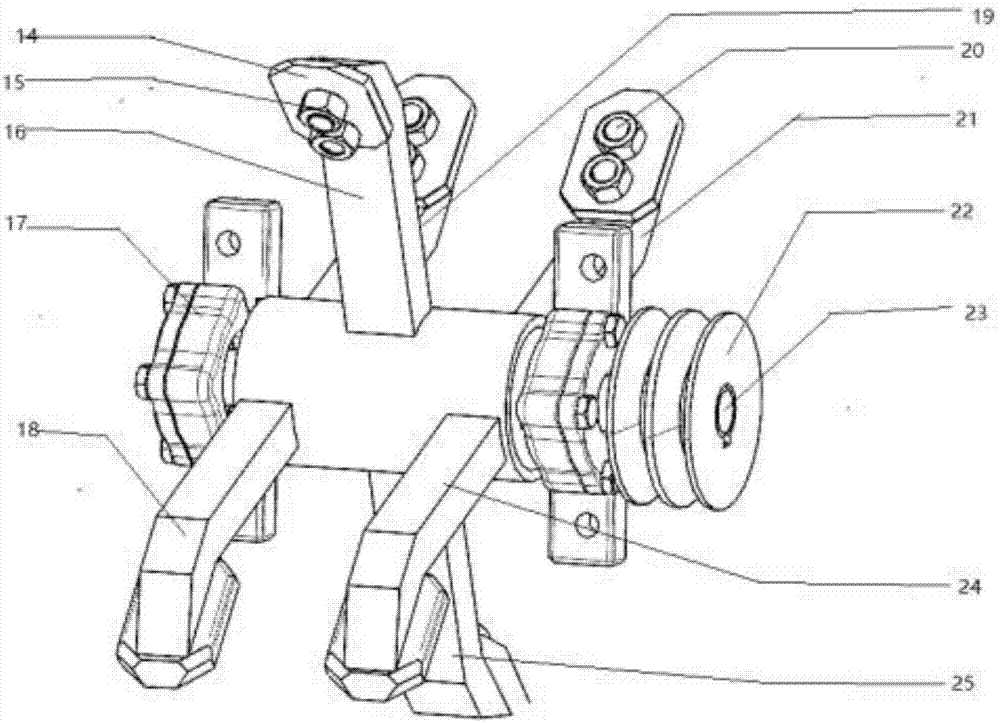

[0036] The tool lifting mechanism is fixed on the front part of the mechanism chassis through nuts and bolts; the excavating mechanism 5 is fixed on the tool lifting mechanism through two bearing seats 17; The middle part of the chassis; the small diesel engine 9 and the reducer 8 are respectively installed on the chassis of the mechanism through bolts and nuts, and the power is transmitted to the excavation mechanism through the belt 38 and pulleys (11, 22), and the hand thrust mechanism is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com