Nano emulsion spray and preparation method thereof

A technology of nano-emulsion and oil phase, which is applied in the field of nano-emulsion spray and its preparation, which can solve the problems of unfavorable skin health, uneven quality, small spray wide angle, etc., and achieve good industrial application prospects, soft atomization effect and excellent preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Preparation method of oil phase part:

[0048] According to the formula shown in Table 1, dissolve and mix the nonionic surfactant, polyol, and water in proportion at 40°C, and record it as A, where nonionic surfactant: polyol: water = (1.1~1.9): ( 1.1~1.9): (0.1~3); under the stirring condition of A, slowly add the oil ester, which is recorded as B; Obtain the oil phase department.

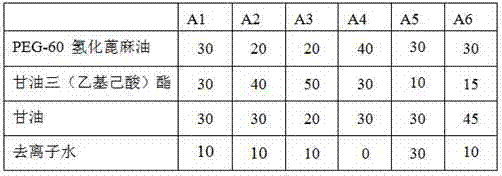

[0049] Table 1 Proportion of oil phase part (weight percentage)

[0050]

Embodiment 1-3 and comparative example 1-3

[0051] Example 1-3 and Comparative Example 1-3: Preparation of Nanoemulsion Spray

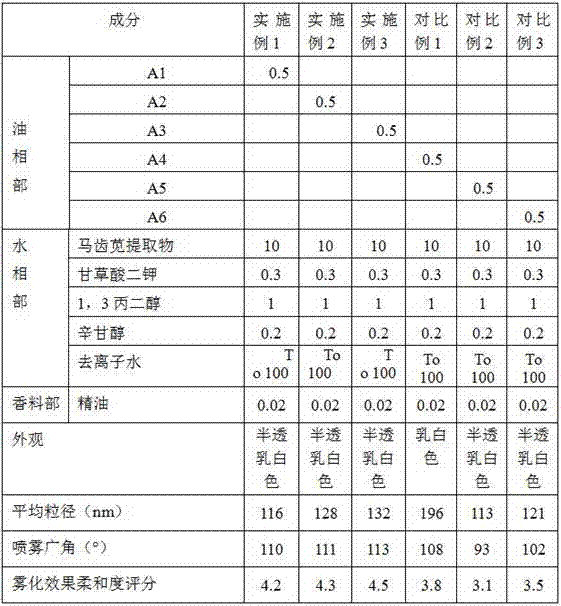

[0052] According to the formula shown in Table 2, the oil phase part is firstly pretreated and set aside; then the fragrance part is added to the oil phase part and mixed uniformly; finally the water phase part is added and stirred evenly to obtain the nanoemulsion spray inner material; the obtained nanoemulsion After the spray inner material is filled through the binary valve spray bottle, the nanoemulsion spray is obtained, and the test performance results are shown in Table 2.

[0053] Table 2 Proportion and performance test results (weight percentage) of the embodiment and the comparative example

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com