Method for preparing chemical engineering iron powder from desulfuration residue iron

A technology for desulfurization slag and iron powder, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of high production cost, complex process flow, low metal iron content, etc., and achieve high grade, simple process flow, The effect of high metallic iron content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

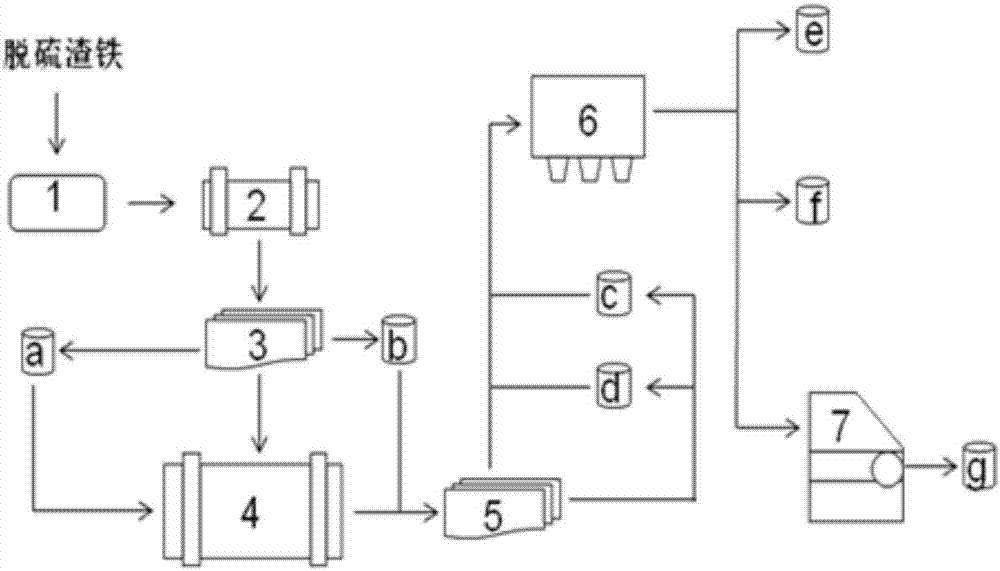

[0028] A method for preparing chemical iron powder from desulfurized slag iron, comprising the following steps:

[0029] 1) Vacuum dry the desulfurized slag and iron at 90-120°C for 2-4 hours, and then perform ball milling pretreatment to peel off the rust layer and non-metallic impurities on the surface. The pretreatment time is 15-30 minutes.

[0030] 2) The pretreated slag and iron pass through 2.36mm and 0.425mm (40 mesh) square hole sieves, the ball milling time for the part above the 2.36mm sieve is 30 to 60 minutes, and the slag iron between 0.425 and 2.36mm is ball milled for 15 to 30 minutes. Separately ball mill finely into iron powder;

[0031] 3) The iron powder below 0.425mm is mixed with the finely crushed iron powder in step 2) and divided into three grades of 40-80 mesh, 80-120 mesh and 120-200 mesh; the 40-80 mesh iron powder is air-selected , the wind speed is 4.1-5.4m / s; the iron powder after winnowing is subjected to magnetic separation, the magnetic field...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com